In the construction and plumbing industry, accurate material planning can make the difference between project success and costly overruns. When working with galvanized iron pipes, understanding weight specifications becomes crucial for transportation, structural load calculations, and cost estimation. A comprehensive gi pipe weight chart serves as your essential reference tool for these critical decisions.

Whether you’re a contractor estimating materials for a water supply project or an engineer designing structural supports, knowing the exact weight per meter of different gi pipes directly impacts your project’s efficiency and budget. This guide provides everything you need to understand, read, and apply GI pipe weight charts effectively in your work.

GI Pipe Weight Chart Tables

To provide a practical reference, below are sample GI pipe weight charts for common pipe sizes and classes. These tables include outer diameter (OD), wall thickness, and weight per meter (kg/mtr) values based on standard IS specifications. Use these tables to quickly estimate pipe weights for your projects.

GI Pipe Weight Chart – Round Pipes (IS 1239 Part 1)

| Nominal Size (inch) | Outer Diameter (mm) | Wall Thickness (mm) | Class A Weight (kg/mtr) | Class B Weight (kg/mtr) | Class C Weight (kg/mtr) |

|---|---|---|---|---|---|

|

1/2″ |

21.3 | 2.77 | 1.02 | 1.27 | 1.56 |

| 3/4″ | 26.7 | 2.87 | 1.28 | 1.58 |

1.94 |

|

1″ |

33.4 | 2.87 | 1.78 | 2.27 | 2.73 |

| 1 1/4″ | 42.2 | 3.25 | 2.46 | 3.11 |

3.79 |

|

1 1/2″ |

48.3 | 3.25 | 2.83 | 3.57 | 4.38 |

| 2″ | 60.3 | 3.65 | 3.68 | 4.63 |

5.56 |

|

2 1/2″ |

73.0 | 4.00 | 4.83 | 6.05 | 7.30 |

| 3″ | 88.9 | 4.00 | 5.87 | 7.35 |

8.87 |

|

4″ |

114.3 | 4.50 | 7.90 | 9.88 | 12.0 |

| 6″ | 168.3 | 5.49 | 13.0 | 16.2 |

19.9 |

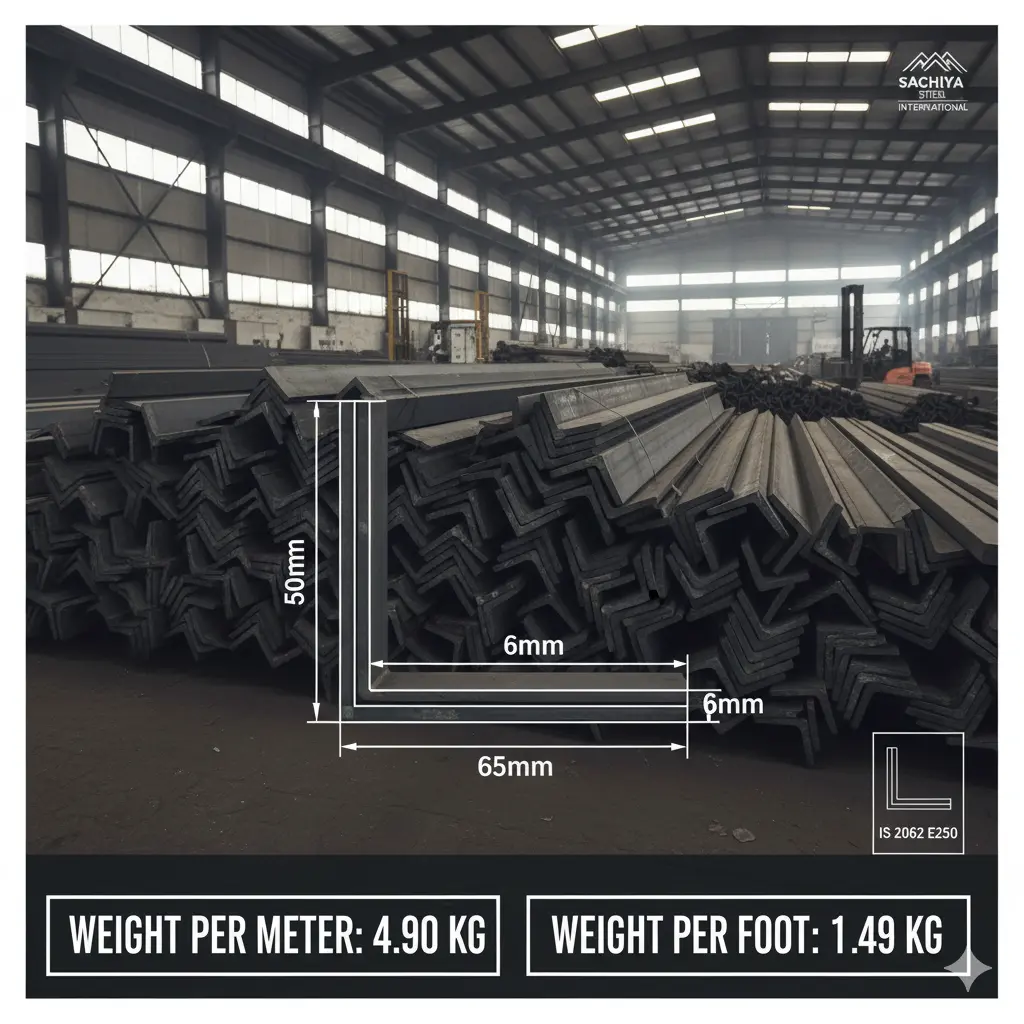

GI Pipe Weight Chart – Square Pipes (IS 1239 Part 1)

|

Size (mm) |

Wall Thickness (mm) | Weight per Meter (kg/mtr) |

|---|---|---|

| 20 x 20 | 1.6 |

0.68 |

|

25 x 25 |

1.6 | 0.84 |

| 32 x 32 | 1.6 |

1.10 |

|

40 x 40 |

2.0 | 1.70 |

| 50 x 50 | 2.5 |

2.60 |

|

65 x 65 |

3.0 | 4.00 |

| 80 x 80 | 3.0 |

4.90 |

|

100 x 100 |

4.0 | 8.20 |

| 125 x 125 | 4.5 |

11.6 |

These tables reflect typical values and may vary slightly based on manufacturer tolerances, zinc coating thickness, and steel grade. Always refer to manufacturer-specific weight charts or verify actual pipe weights when precise calculations are critical.

Including square pipes in your planning is important, as they are widely used in structural frames and fabrication projects, where their weight per meter and moment of gyration are key design parameters.

If you require weight charts for other pipe types such as ERW pipes, or specific grades and finishes like mill cut finish, please request from your supplier or manufacturer directly.

What is a GI Pipe Weight Chart

A gi pipe weight chart functions as a reference table that displays the weight per meter for different pipe sizes, wall thickness variations, and class specifications. These standardized charts serve multiple purposes in construction and engineering projects, primarily helping professionals determine material requirements, calculate transportation costs, and plan structural support systems.

The weight chart typically presents measurements in kilograms per meter (kg/mtr) based on the outer diameter and wall thickness of the galvanized iron pipe. This standardization allows engineers and contractors to make precise calculations regardless of the manufacturer or supplier they choose for their projects.

As an essential tool for engineers, contractors, and suppliers, these charts eliminate guesswork from material estimation processes. When planning a large-scale water distribution project, for example, knowing that a 4-inch Class B gi pipe weighs approximately 12.2 kg/mtr helps determine total material weight, crane capacity requirements, and transportation logistics well before the first pipe arrives on site.

The charts also prove invaluable during procurement processes, where weight-based pricing requires accurate calculations to avoid budget surprises. Most manufacturers provide their own weight charts, but industry standards ensure consistency across different suppliers, making it easier to compare options and maintain quality standards.

How to Read GI Pipe Weight Charts

Understanding pipe nomenclature forms the foundation for reading any pipe weight chart effectively. The three critical measurements you’ll encounter are outer diameter (OD), inner diameter (typically calculated), and wall thickness (d thickness). These dimensions directly determine the pipe’s weight per meter and its suitability for different applications.

Most weight charts organize pipe sizes in inches, starting from smaller residential sizes like 1/2”, 3/4”, and 1”, progressing through commercial sizes like 1.25”, 2”, 3”, and 4”, up to large industrial diameter pipes of 6” and beyond. Each size corresponds to specific weight values across different pipe classes.

When reading weight values in kg/mtr for different pipe classes (A, B, C), remember that Class A represents light duty pipes with the thinnest walls, Class B covers medium duty applications, and Class C indicates heavy duty pipes with the thickest walls. The weight progression follows this pattern consistently across all pipe sizes.

Converting weight per meter to total pipe weight requires a simple multiplication: weight per meter × pipe length. For example, a 2” GI pipe Class B weighs 3.25 kg/mtr. For a 6-meter length, the total weight equals 3.25 kg/mtr × 6 meters = 19.5 kg total weight. This calculation becomes essential when planning transportation and determining handling requirements on site.

The chart format varies between manufacturers, but standard industry practice includes columns for nominal bore size, outer diameter in millimeters, wall thickness specifications, and corresponding weight values. Some charts also include additional information like internal surface area calculations and moment of gyration data for structural applications.

GI Pipe Weight Calculation Methods

The foundation of all gi pipe weight calculations rests on a formula that accounts for the steel material volume and its density. The standard calculation uses the outer diameter, wall thickness, and steel’s density of 7.85 grams per cubic centimeter to determine weight per meter.

The basic formula for weight calculation is: Weight = (OD – WT) × WT × 0.02466 kg/mtr, where OD represents outer diameter in millimeters, WT represents wall thickness in millimeters, and the constant 0.02466 converts the calculation to kg/mtr based on steel density.

For galvanized iron pipes specifically, you must consider additional weight from the zinc coating process. Hot-dip galvanizing typically adds 2-4% to the base mild steel pipe weight, as the zinc coating contributes approximately 85-110 grams per square meter of surface area. This seemingly small addition can significantly impact calculations for large projects.

Manufacturing standards include tolerance limits that affect final weight calculations. According to IS standards, medium and heavy tubes carry a tolerance of ±10%, while light duty pipes maintain ±8% tolerance. These tolerances must factor into calculations when precision matters, particularly for structural applications where load calculations require exact specifications.

When working with ready stock materials from suppliers, always verify actual weight against chart specifications. Manufacturing processes, quality control variations, and different material grade selections can result in weight differences that impact project planning and costs.

GI Pipe Classes and Weight Variations

Class A (Light Duty) GI Pipes

Class A galvanized iron pipes feature the thinnest wall thickness, resulting in the lowest weight per meter across all pipe sizes. These light duty pipes suit applications involving low-pressure water supply systems, domestic plumbing installations, and situations where structural loads remain minimal.

The weight characteristics of Class A pipes make them economical choices for residential projects and temporary installations. A 1/2” Class A pipe weighs approximately 1.02 kg/mtr, while a 1” pipe weighs around 1.78 kg/mtr, and a 2” pipe reaches 2.93 kg/mtr. This progression demonstrates how diameter increases significantly impact weight even in the lightest pipe class.

Despite their lighter construction, Class A pipes still provide adequate corrosion resistance through proper zinc coating application. However, their thinner walls make them less suitable for high-pressure applications or environments where external stress might compromise pipe integrity.

Class B (Medium Duty) GI Pipes

Class B pipes represent the most commonly used classification in general construction and plumbing works. With medium wall thickness specifications, these pipes balance cost, weight, and performance for moderate pressure applications across residential, commercial, and light industrial projects.

Weight specifications for Class B pipes demonstrate the impact of increased wall thickness: 1/2” weighs 1.27 kg/mtr, 1” reaches 2.27 kg/mtr, and 2” pipes weigh 3.25 kg/mtr. This represents roughly 20-25% more weight than equivalent Class A pipes, reflecting the additional steel material in thicker walls.

The versatility of Class B gi pipes makes them suitable for municipal water supply systems, building plumbing installations, and general construction applications where durability and pressure handling capability matter more than minimizing weight.

Class C (Heavy Duty) GI Pipes

Heavy duty Class C pipes feature the thickest wall construction, making them the heaviest option but also the most durable for demanding applications. Industrial facilities, fire fighting systems, and high-pressure installations typically specify Class C pipes for their superior strength and pressure handling capabilities.

The weight progression for Class C pipes reflects their robust construction: 1/2” pipes weigh 1.56 kg/mtr, 1” pipes reach 2.73 kg/mtr, and 2” pipes weigh 4.05 kg/mtr. This represents approximately 35-40% more weight than Class A equivalents, requiring stronger support systems and more substantial transportation planning.

When projects specify Class C pipes, factor in the additional weight for structural support calculations, crane capacity requirements, and transportation costs. The permissible axial compressive stress ratings for these heavy tubes also make them suitable for applications where pipes must bear structural loads beyond simple fluid transport.

GI vs MS Pipe Weight Comparison

Understanding the relationship between galvanized iron and mild steel pipe weights helps clarify pricing and specification decisions. The base weight calculation remains identical for both gi pipes and MS pipes sharing the same dimensions, with the galvanizing process adding the primary weight difference.

Galvanized iron pipes start as mild steel pipes that undergo hot-dip galvanizing, where zinc coating application adds approximately 2-4% to the original weight. This process involves dipping steel pipes in molten zinc, creating a protective layer that prevents oxidation and extends service life significantly.

The galvanizing process adds roughly 85-110 grams per square meter of coating, translating to small but measurable weight increases. For practical applications, a 2” Class B MS pipe weighing 3.25 kg/mtr becomes 3.35-3.40 kg/mtr after galvanizing, demonstrating the modest but consistent weight impact.

This weight relationship becomes crucial for cost calculations, as suppliers often price materials by weight. Understanding that GI pipe weight includes both base steel material and zinc coating helps explain pricing differences and ensures accurate project budgets.

For long-distance transportation or projects involving thousands of meters of pipe, even small weight differences compound significantly. Calculate total project weight using final GI pipe specifications rather than base MS pipe weights to avoid transportation capacity miscalculations.

Indian Standards for GI Pipe Weights

IS 1239 (Part 1) establishes comprehensive specifications for steel tubes used in general engineering purposes, including detailed weight requirements for different pipe classes and sizes. This standard governs manufacturing tolerances, material grade specifications, and quality control procedures that directly impact final pipe weights.

IS 3589 standards specifically address ERW pipes designed for water and sewage applications, ensuring these pipes meet weight specifications appropriate for municipal and industrial fluid transport systems. These standards define wall thickness ranges, diameter tolerances, and corresponding weight calculations that manufacturers must follow.

The galvanizing process itself follows IS 4736 requirements, which specify hot-dip galvanized coating standards for iron and steel articles. This standard ensures consistent zinc coating application that affects final pipe weight and provides uniform corrosion protection across different manufacturers.

Bureau of Indian Standards (BIS) certification requirements mandate that manufacturers demonstrate compliance with weight specifications through regular testing and quality assurance procedures. This certification process helps ensure that pipe weight chart values accurately represent delivered materials.

International alignment with standards like ASTM A53 and BS EN 10255 allows Indian manufacturers to supply pipes meeting global specifications while maintaining domestic standard compliance. This dual compliance capability supports export opportunities while ensuring local project compatibility.

Factors Affecting GI Pipe Weight

Pipe diameter serves as the primary factor determining weight variations, with larger diameters requiring proportionally more steel material for equivalent wall thickness specifications. The relationship between diameter and weight follows mathematical principles where small diameter increases create significant weight changes.

Wall thickness variations significantly impact total weight calculations, as thicker walls require substantially more steel material per meter. The relationship isn’t linear – doubling wall thickness more than doubles the pipe weight due to the larger circumference of material at the outer diameter.

Manufacturing processes affect weight consistency, with seamless pipes typically showing tighter weight tolerances compared to ERW pipes. The welding process in ERW pipes can create slight variations in wall thickness along the seam, potentially affecting overall weight calculations for precise applications.

Quality control standards implemented during manufacturing directly influence how closely actual pipe weights match published chart specifications. Manufacturers with stringent quality control typically deliver pipes with weights within narrow tolerance ranges, while less controlled processes may show wider variations.

The steel grade and chemical composition of base material can create small weight variations even within the same specifications. Different steel compositions may have slightly different densities, affecting final weight calculations, though these differences typically fall within standard tolerances.

Practical Applications of GI Pipe Weight Charts

Material quantity estimation represents one of the most critical applications of pipe weight charts in construction projects. Contractors use these charts to calculate total material weights for transportation planning, determine storage requirements, and estimate handling equipment needs before project commencement.

Transportation planning relies heavily on accurate weight calculations to determine vehicle capacity requirements and shipping costs. When planning to transport 500 meters of 4” Class B GI pipes weighing 12.2 kg/mtr each, the total weight reaches 6,100 kg, requiring appropriate truck capacity and loading equipment.

Structural load calculations for pipe supports and foundations require precise weight data to ensure adequate support systems. Engineers design pipe racks, hangers, and foundations based on total distributed loads that include pipe weight, fluid weight, and safety factors.

Inventory management and warehouse storage planning depend on weight calculations to determine floor loading requirements, storage rack capacities, and material handling equipment specifications. Warehouse managers need these calculations to optimize storage layouts and ensure safe stacking practices.

Crane capacity requirements for lifting and installation work must account for pipe weights plus any lifting hardware. A crane installing 12-meter sections of 6” Class C pipes must handle weights exceeding 400 kg per section, requiring appropriate capacity and safety margins.

Quality control verification during material receipt involves weighing sample pipes to confirm they match specification requirements. Significant weight variations may indicate non-conforming materials or specification errors that could affect project performance.

Popular GI Pipe Brands and Their Weight Standards

Jindal Star gi pipes follow IS 1239 Part 1 weight specifications precisely, providing contractors with reliable weight consistency across different production batches. Their manufacturing process emphasizes tight tolerance control, ensuring that actual pipe weights closely match published chart values for accurate project planning.

Tata gi pipes maintain consistent weight tolerance compliance through advanced quality control systems and regular calibration of manufacturing equipment. Their weight certification process includes batch-wise testing to verify conformance with standard specifications, providing additional confidence for precision applications.

APL Apollo gi pipes meet international quality standards while maintaining compatibility with Indian specifications, allowing contractors to use their weight charts for both domestic and export projects. Their documentation typically includes detailed weight charts with tolerance specifications for each pipe class and size.

Essar Steel galvanized pipes provide accurate weight certification with each shipment, including batch-specific weight data that helps contractors verify material conformance. Their quality control process includes statistical sampling to ensure weight consistency across production runs.

Brand-specific weight charts available from manufacturers often provide more detailed information than generic industry charts, including specific tolerances, coating weights, and material certifications. When precision matters, consulting manufacturer-specific charts provides the most accurate weight data for project calculations.

Different manufacturers may show slight variations in weight due to different steel compositions, galvanizing processes, or quality control standards. For critical applications, specify both the pipe standard and manufacturer to ensure consistent weight characteristics throughout the project.

Understanding gi pipe weight charts empowers construction professionals to make informed decisions about material selection, transportation planning, and structural design. These charts serve as fundamental tools that bridge the gap between theoretical specifications and practical project requirements.

Accurate weight calculations prevent costly surprises during construction, ensure adequate equipment capacity, and support proper safety planning. Whether you’re estimating materials for a small plumbing repair or planning a major infrastructure project, reliable weight data forms the foundation for successful project execution.

For optimal results, always cross-reference weight chart data with manufacturer specifications and account for applicable tolerances in your calculations. This attention to detail ensures your projects proceed smoothly from planning through completion, with materials that meet both weight and performance expectations.