EFW Pipe Manufacturers In India

EFW Pipe Manufacturers In India

Sachiya Steel International Private Limited is India’s leading manufacturer of Electric Fusion Welded (EFW) pipes. Renowned for our excellence and dedication to quality, Sachiya offers an expansive range of EFW pipes to meet the diverse needs of various industries. Our state-of-the-art manufacturing facilities and stringent quality control measures guarantee products of only the highest standards.

Specifications of EFW Pipes

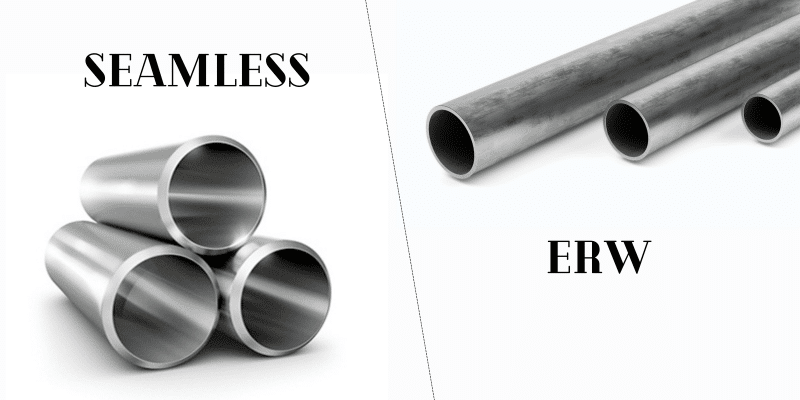

EFW pipes are produced by welding the edges of steel plates or coils to form a cylindrical shape. This method ensures a strong and durable pipe suitable for various applications. Here are the key specifications:

- Standards: ASTM, ASME, API, DIN, EN

- Sizes: 1/8″ NB to 24″ NB

- Schedules: SCH 10 to SCH XXS

- Thickness: 0.5 mm to 25 mm

- Length: Single Random, Double Random, and Custom Lengths

- End: Plain End, Beveled End, Threaded

Chemical and Mechanical Properties

EFW pipes are manufactured using various grades of steel, each with specific chemical and mechanical properties. Below are the details for common grades:

Chemical Composition (%)

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| 304/304L | 0.08 | 2 | 0.045 | 0.03 | 1 | 8.00-10.5 | 18.00-20.00 | – |

| 316/316L | 0.08 | 2 | 0.045 | 0.03 | 1 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.00-12.00 | 17.00-19.00 | – |

Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 304/304L | 515-750 | 205 | 40 |

| 316/316L | 515-750 | 205 | 40 |

| 321 | 515-750 | 205 | 40 |

Pipe Size and Weight Chart

The dimensions and weight of EFW pipes vary significantly, influencing their suitability for different applications. Below is a detailed chart of pipe sizes and corresponding weights:

| Nominal Pipe Size (inches) | Outer Diameter (mm) | Wall Thickness (mm) | Weight (kg/m) |

| 1/8″ | 10.3 | 1.73 | 0.38 |

| 1/4″ | 13.7 | 2.24 | 0.68 |

| 3/8″ | 17.1 | 2.31 | 0.88 |

| 1/2″ | 21.3 | 2.77 | 1.27 |

| 3/4″ | 26.7 | 2.87 | 1.68 |

| 1″ | 33.4 | 3.38 | 2.45 |

| 1 1/4″ | 42.2 | 3.56 | 3.38 |

| 1 1/2″ | 48.3 | 3.68 | 4.05 |

| 2″ | 60.3 | 3.91 | 5.44 |

| 2 1/2″ | 73 | 5.16 | 8.63 |

| 3″ | 88.9 | 5.49 | 11.29 |

| 4″ | 114.3 | 6.02 | 15 |

| 5″ | 141.3 | 6.55 | 19.65 |

| 6″ | 168.3 | 7.11 | 24.97 |

| 8″ | 219.1 | 8.18 | 37.48 |

| 10″ | 273.1 | 9.27 | 54.99 |

| 12″ | 323.9 | 9.53 | 63.29 |

| 14″ | 355.6 | 9.53 | 69.27 |

| 16″ | 406.4 | 9.53 | 79.68 |

| 18″ | 457 | 9.53 | 90.02 |

| 20″ | 508 | 9.53 | 100.36 |

| 24″ | 610 | 9.53 | 121.02 |

Pricing Chart for EFW Pipes

Understanding the pricing structure is crucial for budgeting and planning. The cost of EFW pipes is influenced by factors such as size, grade, and order quantity. Below is an indicative pricing chart (per meter):

| Size (inches) | Grade | Price (INR) |

| 1/2″ | 304/304L | 150 |

| 1″ | 316/316L | 300 |

| 2″ | 321 | 450 |

| 4″ | 304/304L | 700 |

| 6″ | 316/316L | 1050 |

| 8″ | 321 | 1400 |

Grade and Equivalent Grade Table

Selecting the right material grade is essential for ensuring compatibility with various standards and applications. Below is a comparison of different grades across various international standards:

| ASTM/ASME | DIN | EN | JIS |

| 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9 | SUS 304/SUS 304L |

| 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2 | SUS 316/SUS 316L |

| 321 | 1.4541 | X6CrNiTi18-10 | SUS 321 |

Applications of EFW Pipes

EFW pipes have proven themselves indispensable across industries. Below are a few applications where EFW pipes have proven most useful:

- Oil and Gas Industry

EFW pipes are widely utilized in the oil and gas sector for transporting oil, gas, and other fluids. Their ability to withstand high pressures and extreme environmental conditions makes them perfect for this sector.

- Chemical Processing

EFW pipes are widely utilized in chemical plants for safely handling corrosive substances. Their resistance to corrosion and chemical reactions helps ensure longevity and reliability.

- Power Generation

EFW pipes are commonly found in power plants for applications like boilers and heat exchangers, where their ability to withstand high temperatures and pressures are crucial.

- Construction

EFW pipes are widely utilized in both structural applications and plumbing for building projects in the construction industry, due to their strength and durability, making them perfect for creating sturdy infrastructure.

- Water Treatment

EFW pipes are widely utilized in water treatment plants to transport wastewater and potable water, providing maximum purity and safety to their supply chain. Their corrosion-resistance ensures its purity.

Packaging

Packaging our EFW pipes safely for our customers is of utmost importance, so we employ various packaging methods to safeguard our products during transit:

- Bundles: Pipes can be wrapped together and protected using plastic netting to form bundles for easier transportation and installation.

- Crates: Smaller pipes should be stored in sturdy wooden crates to protect from damage during shipping.

- Pipe End Protection: Pipe ends are typically protected with caps to help prevent damage.

- Labeling: Each package is labeled with relevant information such as size, grade, and batch number for easy identification.

Export Country List

Sachiya Steel International Private Limited is proud to serve a global clientele. We export our high-quality EFW pipes to numerous countries across different continents. Here is a list of some of the countries we export to:

| Region | Countries |

| Africa | Nigeria, Egypt, South Africa, Kenya, Ghana, Tanzania |

| Europe | Germany, France, United Kingdom, Italy, Spain, Netherlands |

| Asia | Japan, China, South Korea, Singapore, Malaysia, Thailand |

| Americas | United States, Canada, Brazil, Mexico, Argentina |

| Middle East | United Arab Emirates, Saudi Arabia, Qatar, Kuwait, Oman |

Why Choose Sachiya Steel International Private Limited

- Quality Assurance

Quality Assurance at Sachiya Steel International is our number one priority. We adhere to stringent quality control measures that guarantee every product meets international standards, with in-house testing facilities and certification from recognized bodies ensuring only top quality products reach customers.

- Custom Solutions

Each project has distinct needs. That is why our team works closely with clients to provide tailored solutions, tailored specifically to their sizes, lengths, and grades – to meet those exacting standards.

- Competitive Pricing

We pride ourselves on offering cost-effective solutions at competitive pricing without sacrificing quality. Thanks to efficient manufacturing processes and strategic raw material sourcing, our solutions offer cost-cutting benefits to our customers.

- Timely Delivery

At our company, our robust supply chain and efficient logistics enable us to guarantee timely deliveries of products across the world to all our clients without delay in project schedules or budget. Our dedication to punctuality ensures their projects don’t encounter delays during their schedules.

Sachiya Steel International Private Limited is your go-to source for premium EFW pipes. With our wide range of quality pipes at competitive pricing and outstanding service, clients around the globe turn to Sachiya Steel. Whether they need standard or customized solutions – Sachiya Steel’s experts and dedication ensure they receive only top quality products and services. Contact us now so you can experience what sets Sachiya Steel apart!