SS 304 Price Per Kg | Stainless Steel Price Per Kg & SS Steel Rate 2025

SS 304 stands out in today’s ever-evolving stainless steel market due to its remarkable corrosion resistance and versatility. Understanding the current SS 304 price per kg is of critical importance when purchasing products such as pipes, sheets, coils, tubes and fittings. Pricing dynamics can be affected by several factors, including raw material costs, intricate production methods and ever-evolving market environments. Our platform strives to be your one-stop resource, providing an accessible overview of the current SS 304 price per kg across our array of stainless steel products

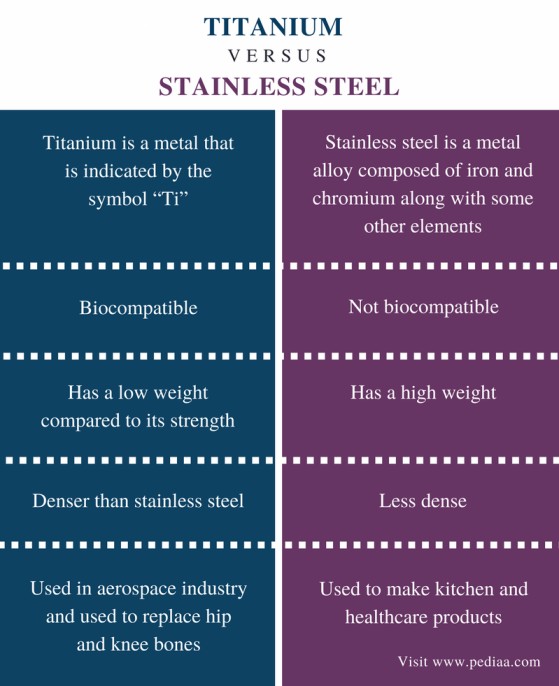

Stainless steel is a versatile and durable material that is used in a wide range of industries, from construction to manufacturing. It is known for its corrosion resistance, strength, and aesthetic appeal. However, with the constantly changing market, it can be challenging to keep up with the stainless steel prices. In this article, we will explore the factors that affect stainless steel prices and how you can stay updated on the current cost.

SS 304 Price Per Kg

| Stainless Steel 304 price per kg |

Origin |

Price in INR (per kg) |

Price in USD (per kg) |

Price in Euro (per kg) |

| SS 304 price per kg in India |

Indian |

Rs 190/- |

$2.68 |

€2.41 |

| SS 304 price per kg in Japan |

Japanese |

Rs 245/- |

$3.46 |

€3.11 |

| SS 304 price per kg in UK / Europe |

European |

Rs 295/- |

$4.16 |

€3.74 |

| SS 304 price per kg in USA |

USA |

Rs 345/- |

$4.87 |

€4.37 |

| ss 304 sheet price per kg |

Indian |

Rs 190/- |

$2.68 |

€2.41 |

Please note: Price is subject to change without any prior notice.

Navigating the vast realm of the stainless steel market, one must recognize the prevailing ss 304 price per kg. As a grade of stainless steel that stands out for its versatility, durability, and affordability, ss 304 is highly sought-after in various industries, from construction to kitchenware. With a substantial market demand and its extensive application, the ss 304 price per kg is a subject of immense interest for manufacturers, suppliers, and consumers alike, given its influence on cost calculations and budget planning. The price per kg can vary significantly based on global market trends, demand and supply balance, and raw material costs.

Understanding Stainless Steel Prices

Stainless steel prices are influenced by various factors, including supply and demand, production costs, and market trends. The price of stainless steel is typically measured in cost per kilogram (kg) or cost per tonne (t). The cost per kg is the most commonly used unit of measurement, and it is what we will focus on in this article.

Indian markets provide access to SS 304 at an incredibly economical cost – around INR 190 per kilogram – making it suitable for a range of applications. Japan prices SS 304 at around $3.46 per kilogram, reflecting its growing global popularity. Europe sees slightly higher per kilogram prices at $4.16 to account for regional market dynamics and import costs; in the US, however, SS 304 can be purchased for approximately $4.87 per kg, which factors in production and distribution expenses.

Are you in search of up-to-date stainless steel prices? Currently, the market provides invaluable information regarding materials such as SS 304 that make up its cost. If you’re curious as to the SS 304 price per kg today, look no further. Stainless steel is a flexible and long-term material widely utilized across industries from construction to manufacturing. Staying informed of its current ss steel price per kg is vitally important to both businesses and individuals alike. steel 304 price per kg may fluctuate based on market dynamics, demand and global factors, making it essential to stay up-to-date on its cost per kilogram if you want to make informed decisions. Knowing this information can assist both manufacturers and consumers alike with planning projects and purchases effectively.

Stainless Steel 304 Price Per Kg In Rupees

Are You Searching for the Current Stainless Steel 304 Price per Kg in Rupees? Stainless steel has become increasingly popular as an industrial material due to its corrosion resistance and long lifespan, and can be found across various industries for use as part of various processes and products.

| SS Grade |

Price per kg in India (INR) |

| Stainless Steel 304 |

Rs 180/Kilogram |

| Stainless Steel 304L |

Rs 185/Kilogram |

| Stainless Steel 304H |

Rs 190/Kilogram |

| Stainless Steel 310/S |

Rs 195/Kilogram |

| Stainless Steel 310H |

Rs 200/Kilogram |

| Stainless Steel 316 |

Rs 220/Kilogram |

| Stainless Steel 316L |

Rs 240/Kilogram |

| Stainless Steel 316Ti |

Rs 250/Kilogram |

| Stainless Steel 317/L |

Rs 230/Kilogram |

| Stainless Steel 347 |

Rs 255/Kilogram |

| Stainless Steel 347H |

Rs 260/Kilogram |

| Stainless Steel 410 |

Rs 355/Kilogram |

| Stainless Steel 446 |

Rs 360/Kilogram |

Factors Affecting Stainless Steel Prices

The basic principle of supply and demand plays a significant role in determining the price of stainless steel. When the demand for stainless steel is high, and the supply is low, the price will increase. On the other hand, when the supply is high, and the demand is low, the price will decrease.

The cost of producing stainless steel is another crucial factor that affects its price. The production process involves various steps, including melting, casting, rolling, and finishing. Each of these steps incurs costs, such as raw materials, labor, and energy. Any changes in these costs can impact the final price of stainless steel.

The stainless steel market is constantly changing, and market trends can significantly impact the price of stainless steel. For example, if there is a sudden increase in demand for stainless steel in a particular industry, the price may rise due to the limited supply. Similarly, if there is a decrease in demand, the price may decrease as well.

Current Stainless Steel Prices

As of today, the average price for stainless steel is around $1.50 per kg. However, this price can vary depending on the type of stainless steel and its grade. Here are some of the current prices for different types of stainless steel:

SS 304: $1.50 – $2.50 per kg

SS 316: $2.50 – $3.50 per kg

SS 430: $1.00 – $1.50 per kg

SS 201: $1.00 – $1.50 per kg

It is essential to note that these prices are subject to change and may vary depending on the supplier and market conditions.

How to Calculate the Cost of Stainless Steel

Calculating the cost of stainless steel can be a bit tricky, as it depends on various factors. However, here is a simple formula you can use to estimate the cost per kg of stainless steel:

Cost per kg = (Raw Material Cost + Labor Cost + Overhead Cost) / Total Weight of Stainless Steel

The raw material cost includes the cost of the raw materials used to produce stainless steel, such as iron ore, nickel, and chromium. The labor cost includes the wages of workers involved in the production process, and the overhead cost includes expenses such as energy, maintenance, and transportation.

Stainless Steel 304 Stockist, SS 304 suppliers in Mumbai

Steel pipes are long, hollow Pipes that are used for a variety of purposes. Stainless Steel pipe and Pipes have excellent corrosion resistance and smooth finishing characteristics. The corrosion resistance of the welded steel pipe is the same as the base metal and the strength higher than the base metal. For these reasons, they are used in demanding industries.

Stainless Steel 304 Suppliers

Stainless Steel 304 Products Suppliers in Mumbai, India, check SS 304 sheet price per kg

| Stainless Steel 304 Pipe |

Stainless Steel 304 Tube |

Stainless Steel 304 Tubing |

Stainless Steel 304 Sheet |

Stainless Steel 304 Plate |

When discussing ss price per kg, one cannot overlook the contribution of Jindal Steel, one of the prominent players in the steel industry. The Jindal steel price per kg is known for its competitive rates without compromising on the quality of the product. The pricing strategy adopted by Jindal Steel contributes mainly to the overall ss price per kg in the market, impacting the affordability and accessibility of high-quality stainless steel for various sectors. With their constant innovation and commitment to sustainability, Jindal Steel remains a crucial determinant in the fluctuating ss 304 price per kg.

AISI Type 304

| Category |

: |

Steel |

| Class |

: |

Stainless steel |

| Type |

: |

Austenitic standard |

| Common Names |

: |

Chromium-Nickel steel |

| Designations |

: |

France: AFNOR Z 6 CN 18.09

Germany: DIN 1.4301 Italy: UNI X 5 CrNi 18 10

Japan: JIS SUS 304 Sweden: SS 2332

United Kingdom: B.S. 302 S 17, B.S. 304 S 15, B.S. 304 S 16, B.S. 304 S 18, B.S. 304 S 25, B.S. 304 S 40, B.S. En.58 E

United States: AMS 5501, AMS 5513, AMS 5560, AMS 5565, AMS 5566, AMS 5567, AMS 5639, AMS 5697, ASME SA182, ASME SA194 (Type 8), ASME SA213, ASME SA240, ASME SA249, ASME SA312, ASME SA320 (B8), ASME SA358, ASME SA376, ASME SA403, ASME SA409, ASME SA430, ASME SA479, ASME SA688, ASTM A167, ASTM A182, ASTM A193, ASTM A194, ASTM A213, ASTM A276, ASTM A312, ASTM A240, ASTM A249, ASTM A269, ASTM A580, ASTM A632, ASTM A651, ASTM A492, ASTM A493, ASTM A270, ASTM A271, ASTM A511, ASTM A554, ASTM A666, ASTM A688ASTM A313, ASTM A314, ASTM A320, ASTM A368, ASTM A376, ASTM A409, ASTM A430, ASTM A473, ASTM A478, ASTM A479, SAE 30304, SAE J405 (30304), UNS S30400, FED QQ-S-763, FED QQ-S-766, FED QQ-W-423, FED STD-66, MIL SPEC MIL-S-23195, MIL SPEC MIL-S-23196, MIL SPEC MIL-S-862, MIL SPEC MIL-S-862, MIL SPEC MIL-T-6845, MIL SPEC MIL-T-8506, MIL SPEC MIL-T-8504, MIL SPEC M.IL-S-5059, MIL SPEC MIL-F-20138 |

Nonetheless, while analyzing ss 304 price per kgs, it is crucial to consider not just the upfront costs but also the long-term benefits. SS 304 offers exceptional corrosion resistance, maintains its structural integrity in high temperatures, and exhibits good formability, making it a cost-effective choice in the long run. Hence, regardless of the ss price per kg, investing in ss 304 can yield significant returns, making it a reliable and cost-effective material for diverse applications.

Stainless Steel 304 Composition Chart

| Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

| 304 |

min. |

– |

– |

– |

– |

– |

18.0 |

– |

8.0 |

– |

| max. |

0.08 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

10.5 |

0. |

Stainless Steel 304 Mechanical Properties

| Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

| Rockwell B (HR B) max |

Brinell (HB) max |

| 304 |

515 |

205 |

40 |

92 |

201 |

Stainless Steel 304 Physical Properties

| Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (m/m/0C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-1000C (J/kg.K) |

Electrical Resistivity (n.m) |

| 0-1000C |

0-3150C |

0-5380C |

at 1000C |

at 5000C |

| 304 |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

304 Stainless Steel Electric Properties

| Properties |

Conditions |

| T (°C) |

Treatment |

| Electric Resistivity (10-9W-m) |

720 |

25 |

|

Equivalent Grades for 304 Stainless Steel

| Grade |

UNS No |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

GOST |

| BS |

En |

No |

Name |

| SS 304 |

S30400 |

304S31 |

58E |

1.4301 |

X5CrNi18-10 |

SS 304 Pipes may be furnished bare or coated and with capped ends. pipes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of SS 304 Pipes may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.

SS 304 Pipes Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

SS 304 Pipes Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

SS 304 Pipes Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and Macro Test

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

SS 304 Pipes Documentation

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- Form A for the purposes of the Generalized System of Preferences (GSP)

Country’s We Export

Venezuela, Iraq, United Kingdom, Russia, United Arab Emirates, Croatia, Indonesia, Oman, Kazakhstan, Israel, Kenya, Iran, Bahrain, Bhutan, Colombia, Serbia, Pakistan, Czech Republic, Turkey, Ukraine, Poland, Bulgaria, France, Chile, Slovakia, Belgium, Iran, Ireland, Qatar, Sri Lanka, Sweden, Brazil, Bolivia, Taiwan, Jordan, South Africa, Switzerland, Tibet, Norway, India, Ghana, Costa Rica, Hungary, New Zealand, Vietnam, Ecuador, Afghanistan, Algeria, Peru, Netherlands, Argentina, Austria, Malaysia, Thailand, Portugal, Zimbabwe, Mongolia, Lebanon, Trinidad & Tobago, Tunisia, Mexico, Greece, Angola, Hong Kong, Denmark, Nepal, Finland, Chile, Poland, Yemen, Nigeria, Italy, Bangladesh, Australia, Macau, Azerbaijan, Saudi Arabia, Japan, Gabon, Philippines, Singapore, United States, Namibia, Romania, South Korea, Germany, Puerto Rico, Estonia, Morocco, Belarus, Nigeria, Mexico, Spain, China, Canada, Libya, Lithuania, Kuwait, Gambia, Egypt.

What is the SS 304 price per kg in 2024?

The SS 304 price per kg in 2024 generally ranges from $2.50 to $3.50 depending on market conditions, raw material costs (like nickel and chromium), and regional factors. For the most accurate pricing, it's best to check with suppliers or online price tracking tools.

Why do SS 304 prices vary across suppliers?

SS 304 prices can vary due to factors like order quantity, location (shipping costs), fluctuations in raw material prices (nickel, chromium), and market demand. Larger orders and regional factors can influence the cost.

What factors affect the SS 304 price per kg?

The price of SS 304 is influenced by raw material costs (nickel, chromium), global demand, supply chain disruptions, geopolitical events, and production costs. Prices can fluctuate based on these dynamic factors.

Is SS 304 a good material for outdoor use?

Yes, SS 304 is ideal for outdoor use due to its high corrosion resistance. It’s commonly used in architectural features, furniture, and outdoor equipment. However, in coastal areas, SS 316 is recommended due to its better resistance to saltwater.

What is the difference between SS 304 and SS 316 in price?

SS 316 is more expensive than SS 304 due to the addition of molybdenum, which enhances its corrosion resistance, especially in chloride-rich environments. SS 304 is more cost-effective for general use but less resistant to harsh conditions.

How do I choose the right stainless steel grade?

Choosing the right stainless steel depends on corrosion resistance, strength needs, and cost. SS 304 is suitable for most general uses, while SS 316 is better for harsh, marine environments. SS 430 is more affordable but has lower corrosion resistance.