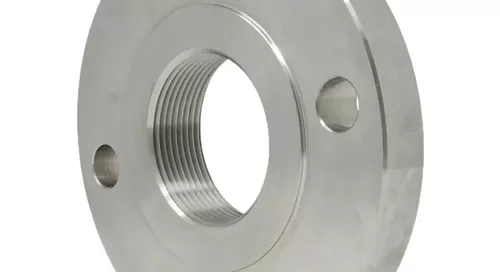

Stainless Steel 304 Threaded Flange Manufacturers in India

Stainless Steel 304 Threaded Flange Manufacturers in India

Sachiya Steel International Private Limited leads the industry as a top Stainless Steel 304 Threaded Flange manufacturer in India. Our reputation is built on delivering high-quality, durable flanges that cater to various industries. We understand the critical role these flanges play in piping systems, making our products reliable and efficient for your needs.

Why Stainless Steel 304 Threaded Flanges?

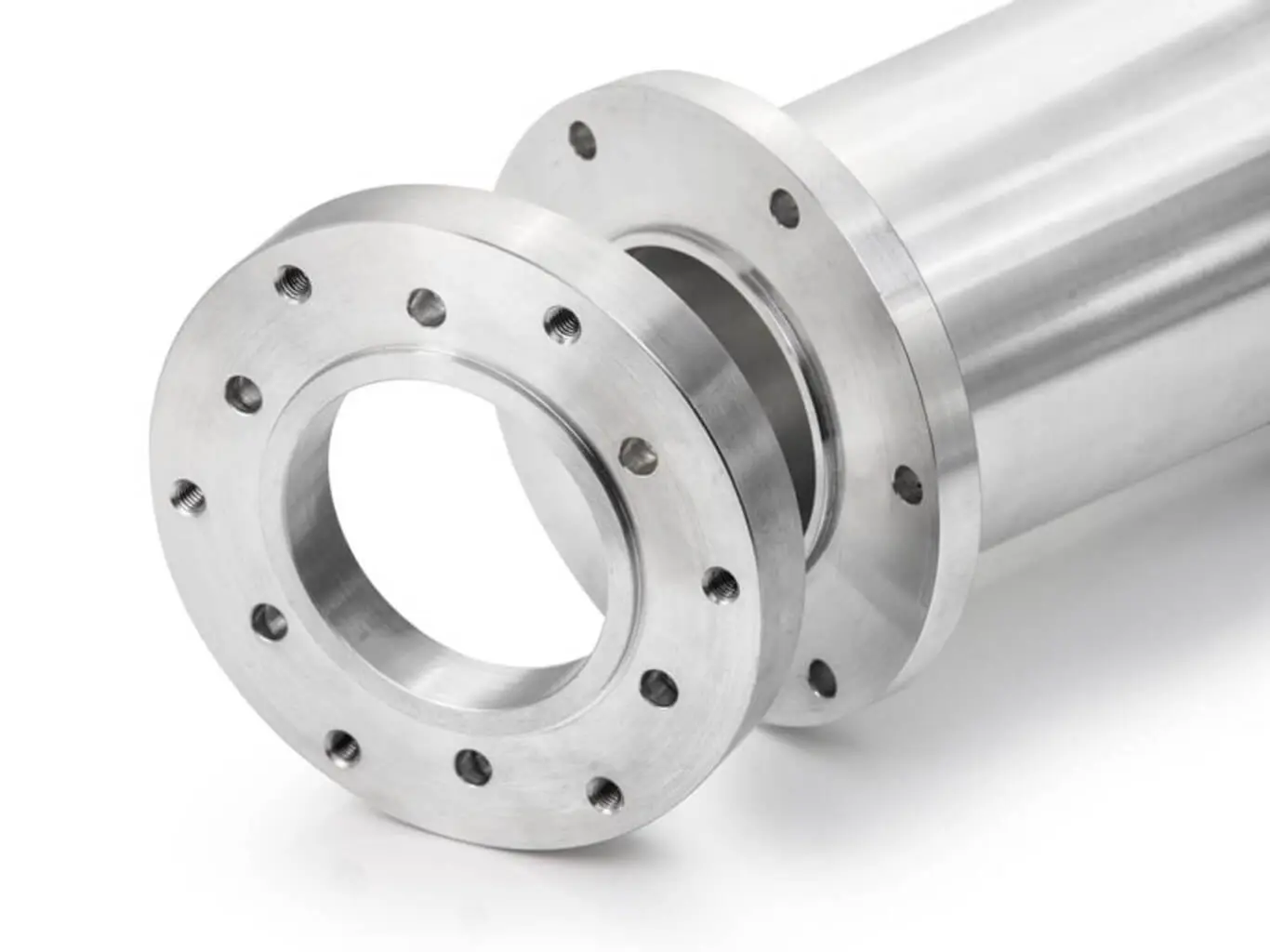

Stainless Steel 304 is a popular choice due to its excellent corrosion resistance, strength, and durability. These qualities make it ideal for threaded flanges, which are essential in piping systems. These flanges allow easy assembly and disassembly, eliminating the need for welding. As a result, they are widely used in industries like oil and gas, petrochemical, chemical processing, and power generation.

We design our Stainless Steel 304 Threaded Flanges to meet the highest standards of quality. Our products deliver consistent performance, whether for high-pressure applications or general use.

Stainless Steel 304 Threaded Flange Specifications

| Specification | Details |

|---|---|

| Material | Stainless Steel 304 |

| Flange Type | Threaded Flange |

| Size Range | 1/2″ NB to 24″ NB |

| Standards | ANSI B16.5, ASME B16.5 |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Face Type | Raised Face (RF), Flat Face (FF) |

| Thread Type | NPT, BSP, BSPT |

| Surface Finish | CNC Machined, Polished |

| Application | Petrochemical, Chemical, Oil & Gas, Power |

| Certification | ISO 9001:2015, CE Mark |

| End Connection | Threaded |

Choose Sachiya Steel International for flanges that last. We manufacture our products using high-quality materials, ensuring durability and resistance to harsh conditions.

Benefits of Choosing Stainless Steel 304 Threaded Flanges from Sachiya Steel International

Customers choose Sachiya Steel International for many reasons:

- High Corrosion Resistance: Stainless Steel 304 flanges resist corrosion effectively, making them suitable for use in harsh environments.

- Superior Strength: Our flanges are designed to handle high pressure and heavy loads, ensuring a secure and leak-free system.

- Wide Range of Sizes: We offer flanges in various sizes, catering to both small and large piping systems.

- Precision Engineering: We ensure a perfect fit through precision engineering, reducing leaks and improving system performance.

- Global Reach: We supply our products globally, ensuring timely delivery and consistent quality, no matter where you are.

Stainless Steel 304 Threaded Flange Price List

Our pricing is competitive, reflecting our commitment to value. Below is a sample price list:

| Size (inches) | Pressure Class | Price (INR per Piece) |

|---|---|---|

| 1/2″ | 150# | ₹150 |

| 3/4″ | 150# | ₹170 |

| 1″ | 150# | ₹200 |

| 1 1/2″ | 150# | ₹250 |

| 2″ | 150# | ₹300 |

| 3″ | 150# | ₹500 |

| 4″ | 150# | ₹700 |

| 6″ | 150# | ₹1,200 |

| 8″ | 150# | ₹2,000 |

| 10″ | 150# | ₹3,500 |

| 12″ | 150# | ₹5,000 |

Note: Prices are subject to change based on market conditions and quantities ordered. Please contact us for the latest pricing.

Why Choose Stainless Steel 304 for Threaded Flanges?

Stainless Steel 304 is the workhorse of the stainless steel family due to its versatility and performance. Here’s why it’s the best choice:

- Versatility: SS 304 is widely used across various applications due to its balanced composition of chromium and nickel. This gives it excellent formability and weldability.

- Ease of Maintenance: SS 304 requires minimal maintenance, making it ideal for industries where cleanliness is a priority.

- Aesthetic Appeal: The bright, shiny surface of SS 304 flanges adds to their aesthetic appeal, which is important in certain applications.

- Availability: As one of the most produced stainless steel grades, SS 304 is readily available, leading to shorter lead times and lower costs.

Chemical Composition of Stainless Steel 304

Stainless Steel 304’s chemical composition contributes to its outstanding properties:

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 2.00 max |

| Silicon (Si) | 0.75 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.030 max |

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 10.5 |

| Nitrogen (N) | 0.10 max |

Mechanical Properties of Stainless Steel 304

The mechanical properties of Stainless Steel 304 are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 515 MPa (min) |

| Yield Strength | 205 MPa (min) |

| Elongation (in 50mm) | 40% |

| Hardness (Brinell) | 201 HB max |

| Hardness (Rockwell B) | 92 HRB max |

Dimensional Chart for Stainless Steel 304 Threaded Flanges

For accurate measurements, refer to the dimensional chart below:

| Size (inches) | OD (mm) | Thickness (mm) | Thread Size (mm) | Pressure Class |

|---|---|---|---|---|

| 1/2″ | 90 | 11 | 15.7 | 150# |

| 3/4″ | 105 | 13 | 20.9 | 150# |

| 1″ | 115 | 14 | 26.4 | 150# |

| 1 1/2″ | 150 | 16 | 38.9 | 150# |

| 2″ | 165 | 18 | 51.4 | 150# |

| 3″ | 210 | 19 | 77.9 | 150# |

| 4″ | 255 | 20 | 102.4 | 150# |

| 6″ | 320 | 21 | 154.3 | 150# |

| 8″ | 380 | 22 | 202.7 | 150# |

| 10″ | 445 | 24 | 254.2 | 150# |

| 12″ | 520 | 26 | 303.2 | 150# |

Export Countries of Sachiya Steel International

We export our Stainless Steel 304 Threaded Flanges globally. Below is a list of countries where we have a strong presence:

| Country | Continent |

|---|---|

| United States | North America |

| Canada | North America |

| United Kingdom | Europe |

| Germany | Europe |

| France | Europe |

| Australia | Australia |

| UAE | Middle East |

| Saudi Arabia | Middle East |

| South Africa | Africa |

| Brazil | South America |

| Singapore | Asia |

| Malaysia | Asia |

| Japan | Asia |

Conclusion

Sachiya Steel International Private Limited is dedicated to delivering the highest quality Stainless Steel 304 Threaded Flanges. With our advanced manufacturing processes, rigorous quality control, and a team of skilled professionals, we ensure that every product meets the highest standards. Whether you’re looking for a reliable supplier for a single project or a long-term partner, Sachiya Steel International is your trusted choice. Contact us today to learn more about our products and services, and let us help you find the perfect solution for your industrial needs.