IS 1239 Pipe Fittings by Sachiya Steel | Leading Manufacturer

IS 1239 Pipe Fittings Manufacturer In India

When it comes to reliable and durable pipe fittings, IS 1239 pipe fittings stand out as a trusted choice in various industrial applications. At Sachiya Steel International Private Limited, India’s leading manufacturer of IS 1239 pipe fittings, we pride ourselves on delivering products that meet the highest standards of quality and performance. In this article, we’ll dive into the essential details about IS 1239 Part 2 pipe fittings, the significance of these standards, and provide you with a detailed pipe fittings chart to guide your selection process.

What Are IS 1239 Pipe Fittings?

IS 1239 is an Indian Standard that specifies the requirements for steel tubes, tubulars, and other fittings that are widely used in industries such as construction, agriculture, automotive, and more. The IS 1239 pipe fittings are engineered to support various piping systems, ensuring a secure and leak-proof connection.

These fittings are manufactured from high-quality carbon steel and are designed to withstand high pressure, corrosion, and mechanical stress. This makes them ideal for use in water, gas, steam, and air pipelines.

IS 1239 Part 2: What You Need to Know

The IS 1239 Part 2 standard specifically focuses on pipe fittings made from carbon steel for use in pressure pipelines. This part of the standard outlines the dimensions, materials, and mechanical properties that these pipe fittings must adhere to. At Sachiya Steel International Private Limited, our IS 1239 Part 2 pipe fittings are manufactured to meet these stringent standards, ensuring that you receive products that are not only reliable but also consistent in quality.

Why Choose IS 1239 Part 2 Pipe Fittings?

- Superior Quality: Our IS 1239 Part 2 pipe fittings are made from the finest materials, ensuring durability and long-term performance.

- Versatility: These fittings are suitable for a wide range of applications, including water distribution, gas pipelines, and steam systems.

- Compliance: We strictly adhere to the IS 1239 Part 2 specifications, ensuring that our products meet all necessary quality and safety standards.

- Customizability: At Sachiya Steel International Private Limited, we offer a variety of sizes and configurations to meet the specific needs of your projects.

Comprehensive Pipe Fittings Chart

Selecting the right pipe fittings is crucial for the success of any piping system. Below is a detailed pipe fittings chart that outlines the dimensions and specifications of the various IS 1239 pipe fittings we offer:

| Fitting Type | Nominal Size (inches) | Outer Diameter (mm) | Wall Thickness (mm) | Material | Application |

| Elbow | 1/2″ – 12″ | 21.3 – 323.9 | 2.77 – 10.31 | Carbon Steel | Water, Gas, Steam |

| Tee | 1/2″ – 12″ | 21.3 – 323.9 | 2.77 – 10.31 | Carbon Steel | Water, Gas, Steam |

| Coupling | 1/2″ – 12″ | 21.3 – 323.9 | 2.77 – 10.31 | Carbon Steel | Water, Gas, Steam |

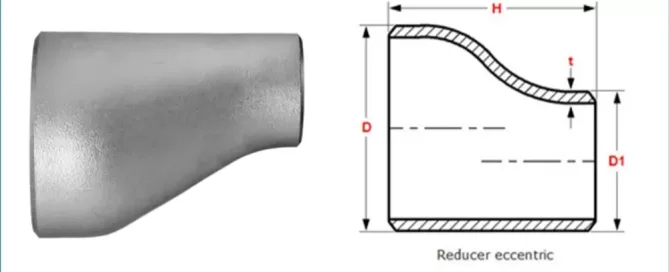

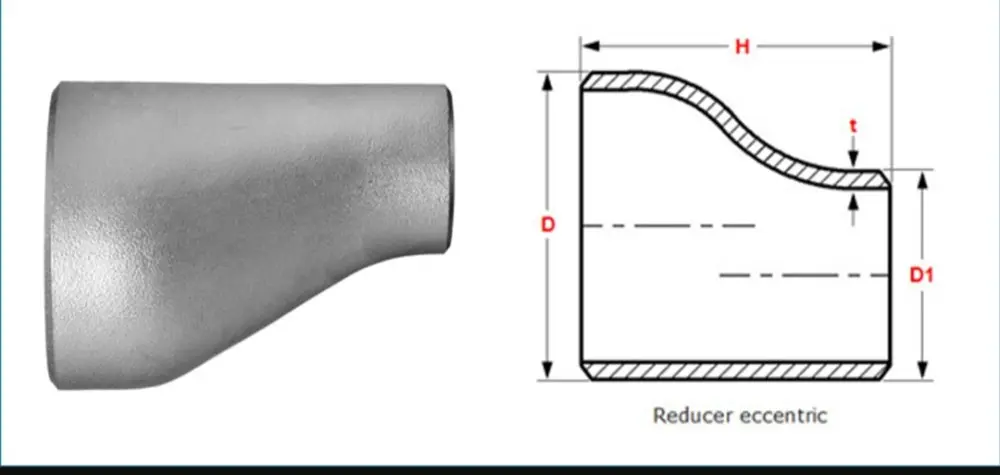

| Reducer | 1/2″ – 12″ | 21.3 – 323.9 | 2.77 – 10.31 | Carbon Steel | Water, Gas, Steam |

| End Cap | 1/2″ – 12″ | 21.3 – 323.9 | 2.77 – 10.31 | Carbon Steel | Water, Gas, Steam |

Note: The above chart is a general guide. For specific requirements, please consult with our technical team.

Why Sachiya Steel International Private Limited?

As India’s leading manufacturer of IS 1239 pipe fittings, Sachiya Steel International Private Limited is committed to delivering products that exceed industry standards. Our state-of-the-art manufacturing facilities, coupled with our rigorous quality control processes, ensure that every fitting we produce is of the highest quality.

- Experience: With years of expertise in the industry, we have built a reputation for reliability and excellence.

- Global Reach: We supply IS 1239 pipe fittings not just within India but to various international markets.

- Customer-Centric Approach: We believe in building long-term relationships with our clients, offering personalized solutions to meet their unique needs.

When it comes to choosing the right pipe fittings, IS 1239 Part 2 pipe fittings from Sachiya Steel International Private Limited offer the perfect blend of quality, durability, and performance. Whether you need fittings for water, gas, or steam pipelines, our products are designed to meet the most demanding requirements.