Introduction to MS Channels

MS channels, or mild steel channels, are fundamental structural elements widely used in construction, engineering, and fabrication projects. Known for their excellent load-bearing capacity and durability, MS channels offer a cost-effective solution for a variety of structural needs. These steel channels are available in a range of sizes and dimensions, making them adaptable for everything from small-scale fabrication to large construction projects.

Accurate knowledge of ms channel weight is essential for project planning, as it impacts both structural design and material estimation. Tools like the weight chart, channel weight calculator, and ismc weight chart help engineers and builders determine the precise channel weight required for their applications. By using these resources, you can ensure optimal use of mild steel channels, manage costs effectively, and achieve reliable structural performance.

MS Channel Weight Chart – The Ultimate Guide for Steel Channel Calculations

Steel channels, including MS Channels, C Channels, and I Channels, are indispensable in construction, manufacturing, and heavy engineering projects. Accurate weight calculations for these steel profiles are crucial for cost management, material selection, and project efficiency.

This guide covers the dimensions and weights of beams, joists, and channels, helping users compare structural sizes for different applications.

Dive into this comprehensive guide, equipped with detailed weight charts, calculators, and resources tailored to your needs. Weight tables are provided to assist in selecting the appropriate steel channel based on project requirements. Whether you’re looking for standard weight sizes, seeking sustainable options, or planning complex projects, we’ve got you covered.

MS Channel Applications

MS channels are prized for their versatility and strength, making them indispensable across numerous industries. In construction, ms channels are commonly used for building frames, roofing supports, and flooring systems, providing robust structural support for both commercial and residential projects. Their excellent load-bearing capacity also makes them ideal for use in material handling equipment, vehicle frames, and machinery structures.

Beyond construction, ms channels serve as essential components in the fabrication of storage racks, warehouse shelving, and support systems for heavy objects. The ability to select the right flange width and ms channel unit weight using a channel weight calculator ensures that each application meets specific load and safety requirements. Whether you’re designing storage solutions or reinforcing vehicle frames, ms channels deliver the strength and reliability needed for demanding environments.

Discover Accurate Tools and Resources

Downloadable MS Channel Weight PDF

To make your calculations easier, we’ve provided an updated and downloadable PDF featuring expanded MS channel weight charts with accurate dimensions and sectional properties. Save time by downloading our high-quality MS Channel Weight Chart PDF.

Interactive Weight Calculator

Don’t forget to use our Interactive Weight Calculator. It offers real-time weight calculations for MS, C, and I channels based on your inputs for web height, flange width, material thickness, and length.

Features:

- Calculate weight per foot, per meter, or for total length.

- Supports custom dimensions for non-standard sizes.

- View and export results in PDF format.

Access it here for reliable results every time.

MS Channel Weight Chart

Here’s a detailed weight chart for commonly used ISMC profiles, ensuring precise dimensions and weights.

|

Size (ISMC) |

Web Height (mm) | Flange Width (mm) | Flange Thickness (mm) | Web Thickness (mm) | Weight (kg/m) | Weight (kg/ft) |

|---|---|---|---|---|---|---|

| ISMC 75 x 40 x 4.8 | 75 | 40 | 4.8 | 4.0 | 7.14 |

2.176 |

|

ISMC 100 x 50 x 5 |

100 | 50 | 5.0 | 4.7 | 9.56 | 2.914 |

| ISMC 125 x 65 x 5.3 | 125 | 65 | 5.3 | 5.0 | 13.10 |

3.993 |

|

ISMC 150 x 75 x 5.7 |

150 | 75 | 5.7 | 5.4 | 16.80 | 5.121 |

| ISMC 175 x 75 x 6.0 | 175 | 75 | 6.0 | 5.7 | 19.60 |

5.975 |

|

ISMC 200 x 75 x 6.2 |

200 | 75 | 6.2 | 6.1 | 22.30 | 6.798 |

| ISMC 250 x 82 x 9 | 250 | 82 | 9.0 | 7.1 | 34.20 |

10.426 |

|

ISMC 300 x 90 x 7.8 |

300 | 90 | 7.8 | 7.6 | 36.30 | 11.067 |

| ISMC 400 x 100 x 8.8 | 400 | 100 | 8.8 | 8.6 | 50.10 |

15.274 |

This table provides the section weight and sectional weight for each mild steel channel unit, making it easy to compare different profiles. To calculate the weight per meter of a channel, you can use the sectional area and multiply it by the density of steel. The size weight of each ISMC profile is also important for accurate cost estimation and material planning in construction projects.

Looking for more sizes? Check our complete weight chart PDF.

Need help with weight calculations? Watch this video for a practical demonstration of using the MS channel weight chart effectively

Joists, Channels, and Angles

Joists, channels, and angles are key structural steel components that form the backbone of many construction and engineering projects. Among these, ms channels—manufactured as hot rolled steel channels—stand out for their distinctive C-shaped profile and adaptability. Available in popular sizes such as ISMC 75 and ISMC 150, these steel channels are designed to handle significant loads while maintaining structural integrity.

The weight of ms channels is typically measured per meter, and accurate calculations are crucial for ensuring the safety and efficiency of support structures. Utilizing a weight chart or channel weight calculator allows engineers to determine the precise channel weight required for joists, beams, and other structural elements. This is especially important in large-scale projects managed by leading steel manufacturers and organizations like india limited, where the weight of beams joists and channels must be carefully coordinated for optimal performance.

Indian Standard Medium (ISM) Channels

Indian Standard Medium (ISM) channels, commonly referred to as ISMC channels, are produced in accordance with the IS 808 code and are available in various grades under IS 2062 standards. These channels are engineered to meet the rigorous demands of the steel industry, offering standardized dimensions for depth, flange width, thickness, and weight per meter. The ismc weight chart and channel weight chart provide essential data for selecting the right channel size and calculating the required material for any project.

For engineers and builders, the channel weight calculator is an invaluable tool for determining the exact weight per meter of ISMC channels, ensuring precise material estimation and structural design. Whether you’re working with indian standard medium channel sizes or custom specifications, these resources help streamline the planning process and guarantee compliance with indian standard requirements. By choosing ISMC channels, you benefit from reliable quality, consistent sectional properties, and the assurance of industry-standard performance.

MS vs C vs I Channels – How to Choose the Right One

Choosing between MS, C, and I channels often depends on the project’s requirements. MS C channel and hot rolled steel channel are common metal types used in construction, each with unique properties and applications. Here’s a side-by-side comparison to make it easier for you to decide.

| Parameter | MS Channel | C Channel | I Channel |

|---|---|---|---|

| Shape | Rectangular C-like | U-Shaped | I-Shaped |

| Stiffness | Moderate | Moderate | High |

| Applications | Structures, EOT cranes | Roofing, Purlins | Bridges, Heavy Loads |

| Weight | Lower | Moderate | Heavy |

| Cost-Effectiveness | High | Moderate | High Investment |

Need help? Request a Quote for custom recommendations based on your specific requirements.

How to Calculate MS Channel Weight

Steel weight calculation becomes seamless with our guide. Here’s how you can manually calculate weight:

Formula

Weight (kg/m) = Volume x Density of Steel (7850 kg/m³)

Steps to Calculate

- Measure the Web height, Flange width, Thickness, and Length.

- Use the formula to calculate weight per meter.

- Multiply the weight per meter by the total length.

Example

For a 100 x 50 x 5mm ISMC, and total length of 12 meters:

- Weight per meter = 9.56 kg/m.

- Total weight = 9.56 x 12 = 114.72 kg.

For quick calculations, use our digital weight calculator.

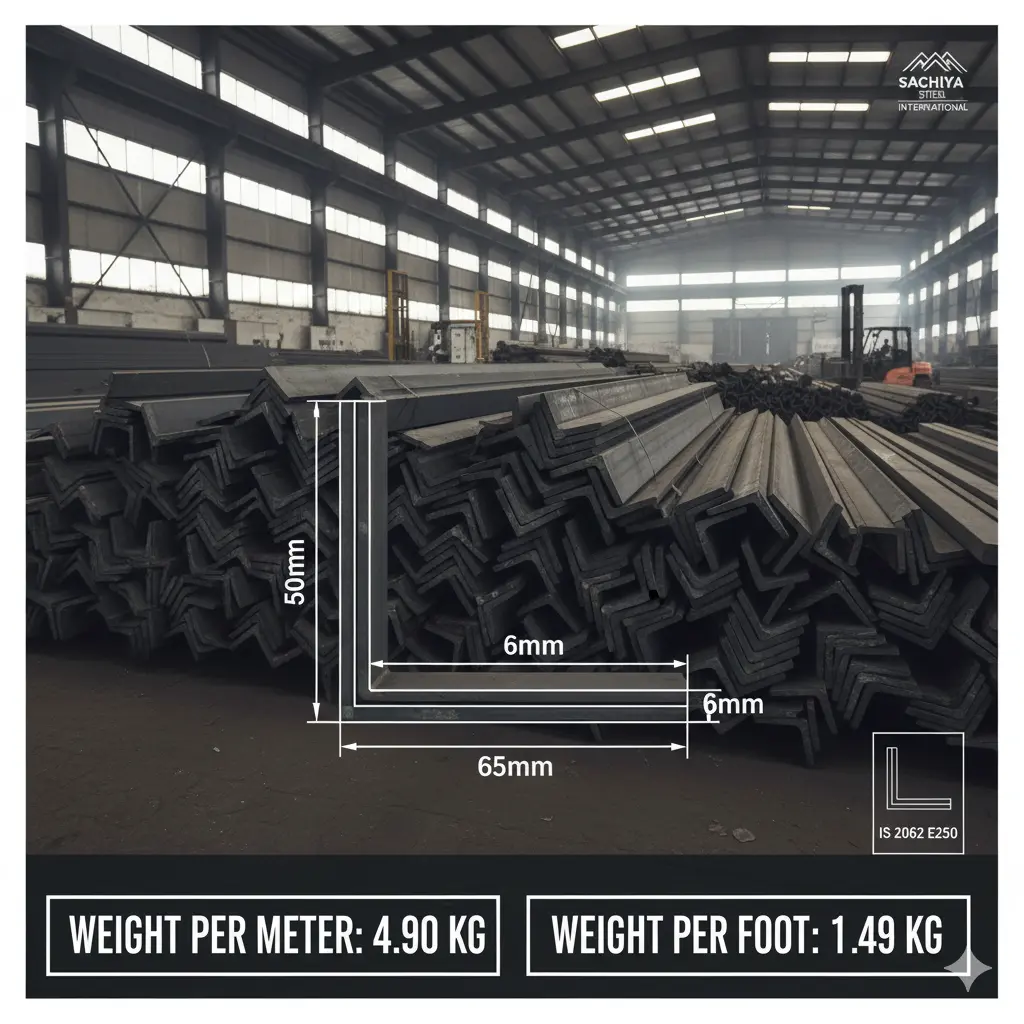

Certifications and Global Delivery

Our steel channels comply with major certifications like IS 2062 E250 for structural applications. Major steel plants such as Bhilai Steel Plant, Rashtriya Ispat Nigam Limited (Vizag Steel Plant), and Steel Authority of India Limited are recognized for producing certified structural steel channels. Sourcing from a reputable steel plant ensures compliance with industry standards.

Regions We Serve

We offer seamless delivery across multiple regions, including:

- Asia: India, UAE, Qatar, and Thailand.

- Europe: Germany, UK, and France.

- North America: USA and Canada.

Why Choose Us?

- Fast shipping to 50+ countries with reliable logistics.

- Fully certified materials meeting industry standards.

How Steel Channels Support Sustainability

Steel is one of the most recycled materials in the world. With over 90% recyclability, it’s a sustainable choice for environmentally conscious projects.

Additionally, the corrosion resistance of steel channels contributes significantly to their long service life and overall sustainability.

Benefits of Steel Channels

- Reduced waste and resource conservation.

- Durable enough to require fewer replacements.

- Energy-efficient manufacturing processes.

Invest in eco-friendly building solutions with quality steel channels.

Looking for more weight charts? Visit our SS pipe weight chart and MS pipe weight chart to find the perfect fit for your project needs.

FAQs for Deeper Insights

1. How do I download the weight chart?

Click here to download the comprehensive MS Channel Weight Chart PDF for offline use.

2. Which standards do MS channels follow?

Common standards include IS 808-1989, IS 2062 E250 (grades A & B), and tolerances as per IS 1852-1985.

3. Can I calculate non-standard channel sizes?

Yes, use our interactive weight calculator to input custom dimensions (length, height, thickness) for instant results.

4. Is global delivery available?

Absolutely. We deliver to Asia, North America, Europe, and beyond. Contact us for your region’s logistics details.

5. What’s the difference between ISMC and C Channels?

While both are C-shaped, ISMCs are industrial-grade profiles with precise IS 808 standards, often heavier and sturdier than commercial C Channels.

Have more questions? Add them in the comments section or get in touch directly!

Take the Next Steps – Download, Calculate, Optimize!

- Compare ISMC profiles using our Calculator.

- Download the MS Channel Weight Chart PDF for complete sizes and sectional details.

- Contact Us for expert consultation or Request a Quote for your unique requirements.

Make your projects efficient and cost-effective with our unmatched resources today!