Stainless Steel Pipe Manufacturers In India

Sachiya Steel International is one of the Leading Manufacturer And Exporter of High Quality stainless steel pipe, we stock over 600 tons in ss seamless and welded pipes. Sachiya Steel International is one of the largest stainless steel pipe supplier in India. Our stainless steel products include stainless steel seamless tube, stainless steel welded tube, ss seamless pipe and ss welded pipe. We supply a large variety of grades in size range of 6mm OD to 610mm OD, with thickness upto 30mm. We manufacture large diameter fabricated stainless steel pipes, high wall thick stainless steel pipes and thin walled stainless steel tubings.

The elements used in the manufacture of any grade Stainless Steel Pipes improves its longevity along with enhancing several of its properties such as corrosion resistance, increased tensile strength & durability. Therefore various grade Stainless Steel Welded Pipes such as alloys 304, 316, 310 etc are used in highly demanding applications involving industries like water, marine, pulp and paper industry, chemical processing, oil and gas, petrochemicals etc.

When alloy grade 316 is used in the manufacture of ASTM A312 Stainless Steel boiler pipes, the resultant pipe can be used in not only high temperature applications, but also general corrosive service. This is because grade 316 electropolished stainless steel pipes has improved resistance to corrosion and is often referred to as a marine grade stainless steel alloy. stainless steel pipe manufacturers in India ,On the other hand, those applications which are less demanding can use alloy grade 304, which although is known to have advantageous properties, is not as good at resisting corrosion in comparison to its austenitic counterpart grade 316 Stainless Steel Pipe.

Stainless Steel Pipe Specifications

| Product | Stainless Steel Pipes |

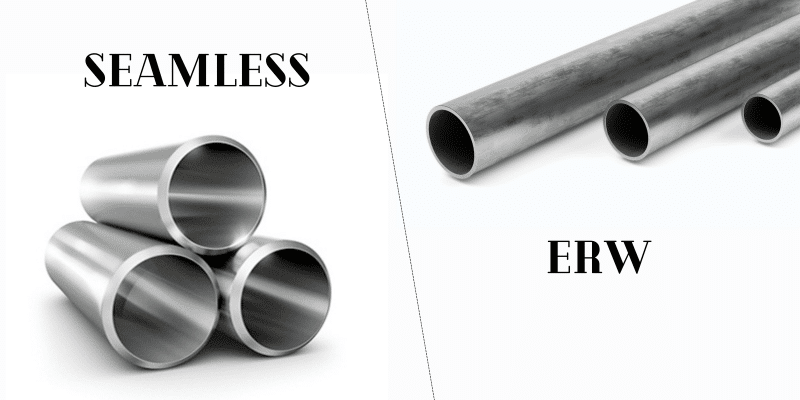

| Type | Seamless, Welded, ERW, 100% X Ray Welded |

| Size OD (mm) | 6.00 to 610.00 |

| Thickness (mm) | 0.5mm to 30mm |

| Length (mm) | 6000, 3000, 2000, 12000, Custom Length |

| Finish | Annealed & Pickled, 2B, No.4, Mirror, Polish |

| Packing | Bundled Packing |

| Services | Cutting, Beveling, Threading, Polishing |

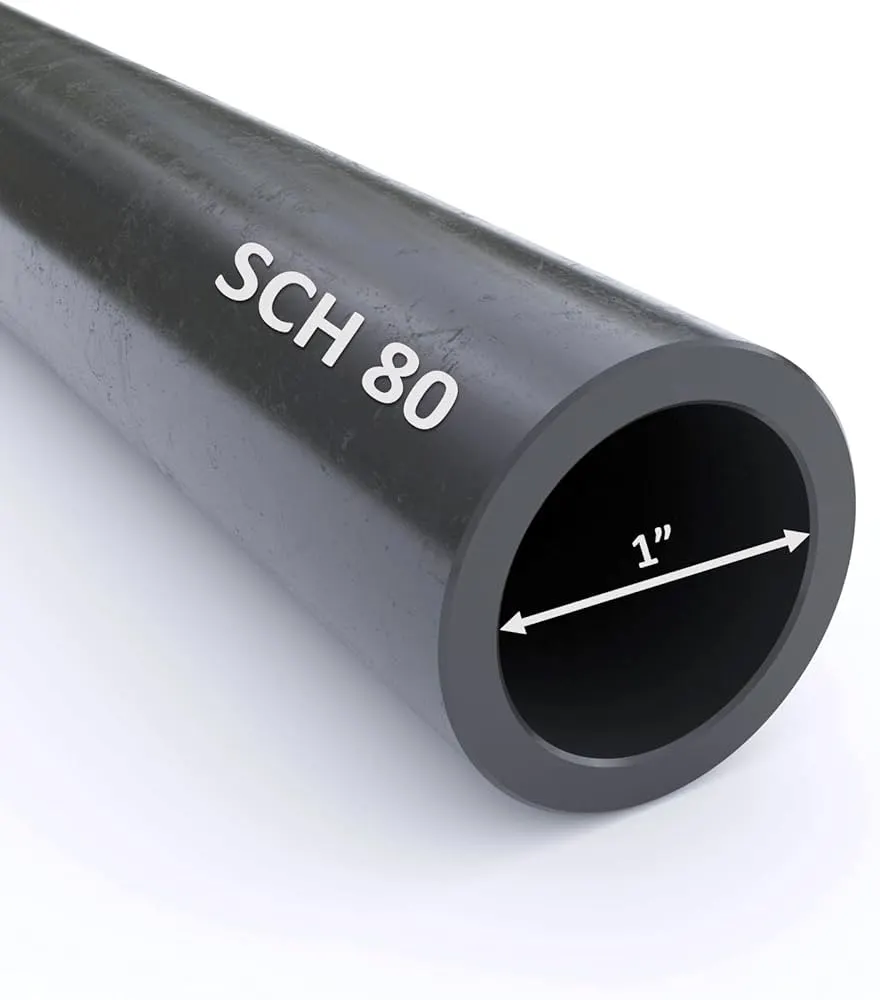

Sachiya Steel International provides ex-stock supply of stainless steel seamless pipes per ASTM A312 in 304/304L, 316/316L/316Ti, 3

21H, SS347H, 317L, 904L and SS446 among other special grades. 304/304L stainless steel pipes/tubes and 316/316L stainless steel pipes/tubes are readily available in all standard pipe sizes and schedules including Sch 5, Sch 10, Sch 40s and Sch 80s. Stainless steel seamless tubes are available in compliance with ASTM A213 and ASTM A269 in common grades of such as 304/304L and 316/316L in standard tube sizes and wall thicknesses. We stainless steel pipe manufacturers in India ,We can offer custom size cold drawn stainless steel pipes and stainless steel tubes to our customers. Generally stainless steel pipes and stainless steel tubes are available in standard OD or NB sizes. However, with our tube processing capabilities we can offer any custom size outside diameter and thickness to our customers.

Stainless Steel Welded Pipes & Tubes

Sachiya Steel International provides ex-stock supply of stainless steel welded pipes in accordance with ASTM A312 in common grades such as 304/304L and 316/316L in standard pipe sizes and schedules including Sch 5, Sch 10, Sch 40s and Sch 80s. We stainless steel pipe manufacturers in India , Sachiya Steel International in the supply of 100% X-Ray Welded custom sizes large diameter fabricated stainless steel pipes. All custom fabricated stainless steel pipe products are accompanied with X-Ray reports and chemical and physical properties certification from NABL approved labs. Specialty testing, including Hydro Testing, Destructive Test, and Non Destructive Test reports can be supplied upon customer request.

Stainless Steel Pipes, Stainless Steel Tubes Testing & Value Added Processing Services from Sachiya Steel International

- Stainless Steel Pipe Polishing

- Stainless Steel Pipe Beveling

- Heat Treatment, Annealing, Pickling

- Ultrasonic Testing

- 100% X-Ray Welding for Large Diameter Custom Size Stainless Steel Pipes

- Tube Processing

- Special Testing Requirements – Destructive Testing, Non Destructive Testing etc.

| Type | Description | USA FOB Price | Malaysia FOB Price | Europe FOB Price | Singapore FOB Price | Saudi Arabia (KSA) FOB Price | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit Per mtr | Unit Per mtr | Unit Per mtr | Unit Per mtr | Unit Per mtr | |||||||

| SS 304 Seamless Pipe | Size : 6″NB x SCH.80S | US $ | 105.85 | Malaysia Ringgit | 430.81 | Euro | 88.91 | Singapore Dollar | 141.84 | Saudi Riyal | 396.94 |

| SS 304 Welded Pipe | Size : 10″NB x SCH.10S | US $ | 66.7 | Malaysia Ringgit | 271.47 | Euro | 56.03 | Singapore Dollar | 89.38 | Saudi Riyal | 250.13 |

| 310S Stainless Steel Pipe / tube | Size : 2″ OD x 2.11mm Thk | US $ | 14.04 | Malaysia Ringgit | 57.14 | Euro | 11.79 | Singapore Dollar | 18.81 | Saudi Riyal | 52.65 |

| 310 Stainless Steel Pipe/ Tubing | Size : 2.1/2″ OD x 2.5mm Thk | US $ | 20.62 | Malaysia Ringgit | 83.92 | Euro | 17.32 | Singapore Dollar | 27.63 | Saudi Riyal | 77.33 |

| 317L Stainless Steel Pipe | Size : 3″NB x SCH.40S | US $ | 85.15 | Malaysia Ringgit | 346.56 | Euro | 71.53 | Singapore Dollar | 114.10 | Saudi Riyal | 319.31 |

| 321 Stainless Steel Pipe | Size : 8″NB x SCH.80S | US $ | 203.91 | Malaysia Ringgit | 829.91 | Euro | 171.28 | Singapore Dollar | 273.24 | Saudi Riyal | 764.66 |

| 347H Stainless Steel Pipe | Size : 3″NB x SCH.XXS | US $ | 151.85 | Malaysia Ringgit | 618.03 | Euro | 127.55 | Singapore Dollar | 203.48 | Saudi Riyal | 569.44 |

| 410 Stainless Steel Pipe | Size : 8″NB x SCH.10S | US $ | 32.91 | Malaysia Ringgit | 133.94 | Euro | 27.64 | Singapore Dollar | 44.10 | Saudi Riyal | 123.41 |

| 446 Stainless Steel Pipe | Size : 12″NB x SCH.10S | US $ | 66.65 | Malaysia Ringgit | 271.27 | Euro | 55.99 | Singapore Dollar | 89.31 | Saudi Riyal | 249.94 |

We stainless steel pipe manufacturers in India ,The elements used in the manufacture of any grade Stainless Steel Pipes improves its longevity along with enhancing several of its properties such as corrosion resistance, increased tensile strength & durability. Therefore various grade Stainless Steel Welded Pipes such as alloys 304, 316, 310 etc are used in highly demanding applications involving industries like water, marine, pulp and paper industry, chemical processing, oil and gas, petrochemicals etc.

When alloy grade 316 is used in the manufacture of ASTM A312 Stainless Steel boiler pipes, the resultant pipe can be used in not only high temperature applications, but also general corrosive service. This is because grade 316 electropolished stainless steel pipes has improved resistance to corrosion and is often referred to as a marine grade stainless steel alloy. On the other hand, those applications which are less demanding can use alloy grade 304, which although is known to have advantageous properties, is not as good at resisting corrosion in comparison to its austenitic counterpart grade 316 Stainless Steel Pipe.

However, it is important to note that due to its affordability as well as enhanced properties, the specified grade 304 ASME B36.19 stainless steel pipes are quite versatile and is considered to be very popular choice of metal in many applications. For instance, in the food industry, particularly the dairy industry uses stainless steel dairy pipes in the processing of acid containing items such as milk. Additionally, the factory uses high temperatures to treat these food groups followed by rapid cooling. Hence this alloy grade 304 or grade 316 ASTM A312 specified high temperature stainless steel seamless pipes needs to be able to withstand both high as well as low temperature settings. To learn more about the price of ASTM A731 Stainless Steel elliptical pipes, you can click the link given here.

Sachiya Steel International is one of the premier quality stainless steel pipe manufacturer in India. We strive to provide customer satisfaction by implementing Quality Management System and continual improvements in products, processes and systems.

Stainless Steel Welded Pipe Manufacturer In India

We stainless steel pipe manufacturers in India, Stainless Steel welded pipe is a long coiled ribbon of steel called skelp. The skelp is cut to the desired length, resulting in a flat rectangular sheet. The shorter ends of sheet’s width become the pipes outside circumference and to calculate it’s eventual outside diameter that value can be used And for forming a cylinder rectangular sheets are fed through a rolling machine that curls the longer sides up toward one another. Stainless Steel erw pipes are manufactured by high-frequency or low-frequency resistance. With longitudinal welds the round pipes are welded from steel plates. It plays an important position in the field of transportation pipes in the world. ERW steel pipes are used to transport natural gas, oil, and other vapour-liquid objects, and also it can meet various requirements of high and low pressure. astm a312 welded pipe contains chromium which gives corrosion resistance properties at high temperature.

It can with stand corrosive or chemical environments. It has excellent forming, toughness and welding characteristic. ASTM A312 pipes are commonly used in demanding equipment like food processing, automobiles, oil and gas processing, water treatment facilities, refinery and petrochemicals, breweries and energy industries. You can buy Large diameter stainless steel welded pipe in above 457 mm and 508 mm from any supplier in India. The diameter of pipe which is larger than its OD is known as large diameter pipe. It plays an important role in oil and gas transmissions. It is used a lot for long distances pipeline projects, since it could carry more liquid and with big flow rate. View SCH 40 Pipe Dimensions in mm.

Other relevant products of Stainless Steel Pipe

stainless steel pipe manufacturers in India, ASTM A790 Stainless Steel high pressure pipe traders, Martensitic Stainless Steel large diameter pipe exporter in Mumbai. Super Ferritic Stainless Steel oval pipe, ANSI B36.19 Stainless Steel pipe manufacturers in India, compare our price with Jindal Stainless Steel pipe price list.

| Stainless Steel Seamless Pipes | Schedule 10 Stainless Steel Pipes |

| Stainless Steel Welded Pipes | 3 Inch Stainless Steel Pipes |

| Stainless Steel Erw Pipes | 4 Inch Stainless Steel Pipes |

| Mirror Finish Stainless Steel Pipes | Large Diameter Stainless Steel Pipes |

| Mirror Polished Stainless Steel Pipes | Large Diameter Seamless Stainless Steel Pipes |

| Brushed Stainless Steel Pipes | Nsf 61 Certified Stainless Steel Pipes |

| Corrugated Stainless Steel Pipes | Nfpa 13 Stainless Steel Pipes |

| Double Wall Stainless Steel Pipes | Oval Shaped Stainless Steel Pipes |

| Dn100 Stainless Steel Pipes | Polished Stainless Steel Pipes |

| Efw Stainless Steel Pipes | Thin Wall Stainless Steel Pipes |

| Electropolished Stainless Steel Pipes | Stainless Steel Hollow Pipes |

| Stainless Steel Elliptical Pipes | Stainless Steel Round Pipes |

| Schedule 40 Stainless Steel Pipes | Seamless SS Transmission Pipes |

| SS Seamless Oil and gas Pipes | Stainless Steel precision Pipes |

ASME B36.19 Stainless Steel Pipe Size Chart

Manufacturer of EN 10217-7 Stainless Steel round pipe, Best quality Stainless Steel pipe and Chromium Nickel Stainless Steel ornamental pipe, Check Martensitic Stainless Steel rectangular pipe & Schedule 40 Stainless Steel electropolished Pipe sizes.

| Dia NPS | OUTSIDE DIAMETER(Milimeter) |

SCH-5S WALL THICKNESS(Milimeter) |

SCH-10S WALL THICKNESS(Milimeter) |

SSCH-40S WALL THICKNESS(Milimeter) |

|---|---|---|---|---|

| 3/8 | 17.15 | 1.65 | 2.31 | |

| 5 | 141.30 | 2.77 | 3.40 | 6.55 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 |

| 1 | 33.40 | 1.65 | 2.77 | 3.38 |

| 1 1/4 | 42.16 | 1.65 | 2.77 | 3.56 |

| 1 1/2 | 48.26 | 1.65 | 2.77 | 3.68 |

| 4 | 114.30 | 2.11 | 3.05 | 6.02 |

| 2 | 60.33 | 1.65 | 2.77 | 3.91 |

| 2 1/2 | 73.03 | 2.11 | 3.05 | 5.16 |

| 1/2 | 21.34 | 1.65 | 2.11 | 2.77 |

| 3 | 88.90 | 2.11 | 3.05 | 5.49 |

| 3 1/2 | 101.60 | 2.11 | 3.05 | 5.74 |

| 1/4 | 13.72 | 1.65 | 2.24 | |

| 6 | 168.28 | 2.77 | 3.40 | 7.11 |

| 8 | 219.08 | 2.77 | 3.76 | 8.18 |

| 10 | 273.05 | 3.40 | 4.19 | 9.27 |

| 12 | 323.85 | 3.96 | 4.57 | 9.53 |

| 14 | 355.60 | 3.96 | 4.78 | 9.53 |

| 24 | 609.60 | 5.54 | 6.35 | 9.53 |

| 16 | 406.40 | 4.19 | 4.78 | 9.53 |

| 18 | 457.20 | 4.19 | 4.78 | 9.53 |

| 20 | 508.00 | 4.78 | 5.54 | 9.53 |

| 22 | 558.80 | 4.78 | 5.54 | |

| 30 | 762.00 | 6.35 | 7.92 | |

| 32|

80 |

812.8|

2032.0 |

(Thickness):6.35~30mm

Nominal diameter and wall thickness subject to the approval of vendor and purchaser |

||

Production, Supply, Stock Range of Stainless Steel Pipes and Stainless Steel Tubes

| Stainless Steel Pipe Manufacturing Grades | |

| Austenite Stainless Steel Pipe Grades | 304/304L, 316/316L, 304H, 304LN, 316Ti, 310S, 904L, 317L, 321/321H, 347/347H |

| Martensite Stainless Steel Pipes Grades | 446, 410S |

| Duplex Stainless Steel Pipes Grades | S31803, S32205, S32750, Duplex 2205, Super Duplex 2507 |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness Range | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| End Protection | Plastic Caps |

| Surface Finish: | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

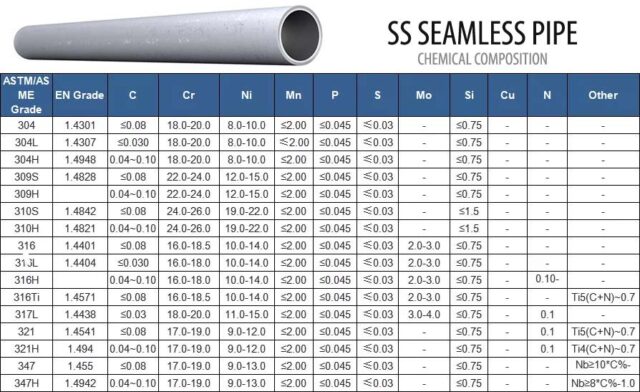

Chemical Composition of Stainless Steel Pipes, as per ASTM A312 Manufacturing Standard

The below table shows the chemical composition of the most used A312 Stainless Steel Pipes:

| A312 GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP304H | S30409 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304N | S30451 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-18.0 | 0.10-0.16 | |||

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | 0.10-0.16 | |||

| TP309S | S30908 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | 0.75 | |||

| TP309H | S30909 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | ||||

| TP309Cb | S30940 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP309HCb | S30941 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP310S | S3108 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | |||

| TP310H | S3109 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | ||||

| TP310Cb | S31040 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP310HCb | S31041 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min | ||

| 1.10 max | ||||||||||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |||

| TP316H | S31609 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316Ti | S31635 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 5x | 0.1 | |

| (C-N) | ||||||||||||

| -0.7 | ||||||||||||

| TP316N | S31651 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP317 | S3170 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 10.0-14.0 | 3.0-4.0 | |||

| TP317L | S31703 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |||

| TP321 | S3210 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP321H | S32109 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 0.1 | |||

| TP347 | S3470 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347H | S34709 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347LN | S34751 | 0.05-0.02 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | 0.20- | 0.06-0.10 | ||

| 50 | ||||||||||||

| TP348 | S3480 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 | ||||

| TP348H | S34809 | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-13.0 |

Mechanical Properties of Stainless Steel Pipes, as per ASTM A312

| ASTM A312 Mechanical Properties | |||||

| Material | Heat | Temperature | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP304H | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP310S | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

| TP316H | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316Ti | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP321 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP321H | Solution | Cold: 2000(1100) | 75(515) | 30(205) | 35 |

| Hot: 1925(1050) | |||||

| TP347 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP347H | Solution | Cold: 2000(1100) | 75(515) | 30(205) | |

| Hot: 1925(1050) | |||||

Dimensions of Welded and Seamless Stainless Steel Pipe

| NPS | Outside Diameter | Nominal Wall Thickness | ||||||||

| Designator | in. | mm | Schedule 5S | Schedule 10S | Schedule 40S | Schedule 80S | ||||

| in. | mm | in. | mm | in. | mm | in. | mm | |||

| 1/8 | 0.41 | 10.29 | … | … | 0.049 | 1.24 | 0.068 | 1.73 | 0.095 | 2.41 |

| 1/4 | 0.54 | 13.72 | … | … | 0.065 | 1.65 | 0.088 | 2.24 | 0.119 | 3.02 |

| 3/8 | 0.68 | 17.15 | … | … | 0.065 | 1.65 | 0.091 | 2.31 | 0.126 | 3.2 |

| 1/2 | 0.84 | 21.34 | 0.065 | 1.65 | 0.083 | 2.11 | 0.109 | 2.77 | 0.147 | 3.73 |

| 3/4 | 4.05 | 26.67 | 0.065 | 1.65 | 0.083 | 2.11 | 0.113 | 2.87 | 0.154 | 3.91 |

| 1 | 1.32 | 33.4 | 0.065 | 1.65 | 0.109 | 2.77 | 0.133 | 3.38 | 0.179 | 4.55 |

| 1 1/4 | 1.66 | 42.16 | 0.065 | 1.65 | 0.109 | 2.77 | 0.14 | 3.56 | 0.191 | 4.85 |

| 1 1/2 | 1.90 | 48.26 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.68 | 0.2 | 5.08 |

| 2 | 2.38 | 60.33 | 0.065 | 1.65 | 0.109 | 2.77 | 0.154 | 3.91 | 0.218 | 5.54 |

| 2 1/2 | 2.88 | 73.03 | 0.083 | 2.11 | 0.12 | 3.05 | 0.203 | 5.16 | 0.276 | 7.01 |

| 3 | 3.50 | 88.9 | 0.083 | 2.11 | 0.12 | 3.05 | 0.1216 | 5.49 | 0.3 | 7.62 |

| 3 1/2 | 4.00 | 101.6 | 0.083 | 2.11 | 0.12 | 3.05 | 0.226 | 5.74 | 0.318 | 8.08 |

| 4 | 4.50 | 114.3 | 0.083 | 2.11 | 0.12 | 3.05 | 0.237 | 6.02 | 0.337 | 8.56 |

| 5 | 5.56 | 141.3 | 0.10*9 | 2.77 | 0.134 | 3.4 | 0.258 | 6.55 | 0.375 | 9.52 |

| 6 | 6.63 | 168.28 | 0.10*9 | 2.77 | 0.134 | 3.4 | 0.28 | 7.11 | 0.432 | 10.97 |

| 8 | 8.63 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.5 | 12.7 |

| 10 | 10.75 | 273.05 | 0.134 | 3.4 | 0.165 | 4.19 | 0.365 | 9.27 | 0.5 | 12.7 |

| 12 | 12.75 | 323.85 | 0.156 | 3.96 | 0.18 | 4.57 | 0.375 | 9.52 | 0.5 | 12.7 |

| 14 | 14.00 | 355.6 | 0.156 | 3.96 | 0.188 | 4.78 | … | … | … | … |

| 16 | 16.00 | 406.4 | 0.165 | 4.19 | 0.188 | 4.78 | … | … | … | … |

| 18 | 18.00 | 457.2 | 0.165 | 4.19 | 0.188 | 4.78 | … | … | … | … |

| 20 | 20.00 | 508 | 0.188 | 4.78 | 0.188 | 4.78 | … | … | … | … |

| 22 | 22.00 | 558.8 | 0.188 | 4.78 | 0.218 | 5.54 | … | … | … | … |

| 24 | 24.00 | 609.6 | 0.218 | 5.54 | 0.25 | 6.35 | … | … | … | … |

| 30 | 30.00 | 762 | 0.25 | 6.35 | 0.312 | 7.92 | … | … | … | … |

Outside Diameter Tolerance of Stainless Steel Pipes

| NPS | ASTM A312 OD Tolerance | |||

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 | 1/64(0.015) | 0.4 | 1/32(0.031) | 0.8 |

| > 1 1 /2~4 | 1/32(0.031) | 0.8 | 1/32(0.031) | 0.8 |

| > 4~8 | 1/16(0.062) | 1.6 | 1/32(0.031) | 0.8 |

| > 8~18 | 3/32(0.093) | 2.4 | 1/32(0.031) | 0.8 |

| > 18~26 | 1/8(0.125) | 3.2 | 1/32(0.031) | 0.8 |

| > 26~34 | 5/32(0.156) | 4 | 1/32(0.031) | 0.8 |

| > 34~48 | 3/16(0.187) | 4.8 | 1/32(0.031) | 0.8 |

Wall Thickness Tolerance of Stainless Steel Pipes

| NPS | ASTM A312 WT Tolerance, % | |

| + | – | |

| 1/8-2 1 /2 | 20 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15 | 12.5 |

Premier Stainless Steel Tube Manufacturers in India -Sachiya Steel International

Improve your projects with the superior quality of Sachiya Steel International, a trailblazing name among stainless steel tube manufacturers in India. Our commitment to outstanding quality and cutting-edge solutions is unrivalled, and we have a solid reputation as a premier SS tube manufacturer in India. With modern production facilities that pioneer the industry in producing a wide range of stainless steel tubes, Sachiya Steel International takes fulfilment in providing them.

Sachiya Steel International, a reputable ss tube manufacturer in India goes above and beyond expectations. Our extensive selection of precisely made ss tubes is known for its remarkable toughness, corrosion resistance, and dimensional perfection. We serve a variety of industries as one of the top producers of stainless steel tubes in India, providing solutions compliant with high international standards. To give our clients a competitive edge for their projects, in addition to receiving stainless steel tubes, we consistently push the boundaries of innovation.

Rely on Sachiya Steel International’s reputation for dependability. Renowned as a top-tier SS tube manufacturers in India, our wide selection of stainless steel tubes reflects our commitment to superior quality. In addition to providing stainless steel tubes, we also create enduring relationships. Beyond being a mere supplier of stainless steel tubes, we forge lasting partnerships. We contribute to the nation’s industrial growth story while keeping an eye on the world markets and a heart firmly planted in India. Choose Sachiya Steel International for stainless steel tubes that are the epitome of perfection because of their precision, honesty, and superiority.

Stainless Steel Pipes Manufacturing Specifications

ASTM A312: Seamless and straight-seam welded austenitic pipe intended for high temperature and general corrosive service. Filler metal not permitted during welding.

ASTM A358: Electric fusion welded austenitic pipe for corrosive and/or high temperature service. Typically only pipe up to 8 inch is produced to this specification. Addition of filler metal is permitted during welding.

ASTM A790: Seamless and straight-seam welded ferritic/austenitic (duplex) pipe intended for general corrosive service, with a particular emphasis on resistance to stress corrosion cracking.

ASTM A409: Straight-seam or spiral-seam electric fusion welded large diameter austenitic light-wall pipe in sizes 14” to 30” with walls Sch5S and Sch 10S for corrosive and/or high

ASTM A376: Seamless austenitic pipe for high temperature applications.

ASTM A813: Single-seam, single- or double- welded austenitic pipe for high temperature and general corrosive applications.

ASTM A814: Cold-worked welded austenitic pipe for high temperature and general corrosive service.

| Sr. No. | Description | Sizes | Thickness | Price/Kg in Rs. | Price in US$/kg |

| Stainless Steel Seamless Pipes | Domestic Sales to India | Export Price | |||

| 1 | ASTM A312 TP 304 Seamless Pipes | 11/2″ to 4″ | SCH 10 & SCH 40 | 270 | 3.5 |

| 2 | ASTM A312 TP 304 Seamless Pipes | 1″ | SCH 10 & SCH 40 | 295 | 3.40 |

| 3 | ASTM A312 TP 304 Seamless Pipes | 6″ | SCH 10 & SCH 40 | 310 | 4.30 |

| 4 | ASTM A312 TP 316L Seamless Pipes | 11/2″ to 4″ | SCH 10 & SCH 40 | 360 | 4.95 |

| 5 | ASTM A312 TP 316L Seamless Pipes | 1″ | SCH 10 & SCH 40 | 390 | 5.40 |

| Stainless Steel Welded/ERW Pipes | |||||

| 1 | ASTM A312 TP 304 ERW Pipes | 1″ to 4″ | SCH 10 & SCH 40 | 195 | 2.90 |

| 2 | ASTM A312 TP 304 ERW Pipes | 6″ | SCH 10 & SCH 40 | 220 | 3.20 |

| 3 | ASTM A312 TP 316L ERW Pipes | 1″ to 4″ | SCH 10 & SCH 40 | 290 | 4.20 |

| 4 | ASTM A312 TP 316L ERW Pipes | 6″ | SCH 10 & SCH 40 | 320 | 4.70 |

| Stainless Steel Polished Pipes, 600 Grit | |||||

| 1 | ASTM A554 304 Pipes | 1″ to 3″ | 1.2mm, 1.5mm | 200 | 2.95 |

| 2 | ASTM A554 201 Pipes | 1″ to 3″ | 1.2mm, 1.5mm | 140 | 1.85 |

| 3 | ASTM A554 316 Pipes | 1″ to 3″ | 1.2mm, 1.5mm | 305 | 4.30 |

Some of the major locations we have supplied ss seamless and welded pipes

| Products | We supplied to following Locations |

|---|---|

| 40 mm NB, SS Seamless Pipe, Schedule 40 | Indonesia, Dammam -KSA, Philippines, Belgium |

| Ferritic martensitic steel seamless pipes | France, Qatar, Europe, Thailand |

| 50mm ASTM A 312 Stainless Steel Seamless Pipe | Germany, Czechia, Thailand, Malaysia |

| Jindal/ Tata Make Schedule 40 Seamless Pipes | USA, Malaysia, Bangladesh, Finland |

| ASTM A269 Seamless Pipe | Saudi Arabia (KSA), South Africa, Kuwait, Brazil |

| SS ERW and Seamless Pipes | South Africa, Singapore, Bahrain |

| BE 18″ SCH STD, ASME B 36.19M Stainless Steel Seamless Pipe | Australia, Philippines, UK, Nigeria |

| Stainless steel pipe for chilled water, ANSI B36.19 | Malaysia, Oman, Hong Kong |

| 8″ NB SCH 5 SS SEAMLESS PIPE | Italy, Chile, Iran, Singapore |

| ASTM 312 Pipe Seamless, DN150, SCH – 10S | Turkey, United Arab Emirates (UAE), Norway |

| Schedule 20 Seamless round pipe | Malaysia, Netherlands, Russia |

| 1.5” NPS Austenitic stainless steel seamless pipes | Spain, Egypt, Mexico, UK, Singapore |

| SS ERW Round Pipe | Europe, United Kingdom -UK, Malaysia |

| SS seamless pipe in schedule 60 | Canada, Ellington -United States, UK |

| sch20 Food grade SS Pipes | Malaysia, Philippines, Canada, Singapore |

| Sch 5, annealed, seamless, cold finish pipes | Japan, Europe, Romania, Poland |

| ASME SA213 Stainless pipe annealed pickled expanding | Colombia, Sweden, Malaysia, China |

| Stainless Steel Welded Pipes | Taiwan, Philippines, Los Alamos -Mexico |

| BE SCH 10S SEAMLESS PIPES AS PER ASME B36.19 | South Korea, Singapore, NY 12203 (USA) |

Buy from stainless steel welded pipe manufacturer in India to ensure high quality at better price, also you can save the wastage if buy the exact sizes

|

|

Stainless Steel Pipe Chemical composition

General queries of our customers about Stainless Steel Seamless Pipes

- What is the minimum diameter and maximum size in seamless pipe?

Ans: Minimum OD: 16 inch, 406.4 mm

Maximum OD: 20 inch, 508 mm - What is the price difference between Seamless & Welded Pipe in India?

Ans: Seamless steel pipe cost is almost 40-50% higher compared to the welded pipes due to manufacturing process & raw material, click here to view the updated Stainless Steel Seamless Pipe Price List. - What is the maximum pressure of SCH40 Seamless Pipes?

Ans: Pressure rating depends upon sizes, wall thickness & temperature. For example:

1″ SCH40 WT 0.133, 100°F = 2205 PSi

10″ SCH40 WT 0.365, 100°F = 699 Psi - Why in high pressure applications SS Seamless Pipe is preferred?

Ans: Welded pipe can be cracked on high pressure while Seamless Pipes can withstand extremely high pressure without cracking. So seamless pipe can take 20% higher pressure compared to welded. - What is the weight difference between Welded and Seamless Pipe?

Ans: The welded pipe is 30% heavier compared to seamless pipe because of welding of HR coil, don’t forget to check SS Pipe Weight Chart.

Stainless Steel Pipe

Leading Stainless Steel Pipe Manufacturers in India - Your trusted source for high-quality stainless steel pipes. We are a top SS pipe manufacturer and supplier, offering a wide range of stainless steel pipes, including seamless options. Discover durable and corrosion-resistant stainless steel pipes for various industrial applications.

Product Brand: Sachiya Steel International

Product Currency: INR

Product Price: 100

Price Valid Until: 2025-05-31

Product In-Stock: InStock

5