Stainless Steel 410 Slip On Flange Manufacturers In India

Introduction to Stainless Steel 410 Slip On Flanges

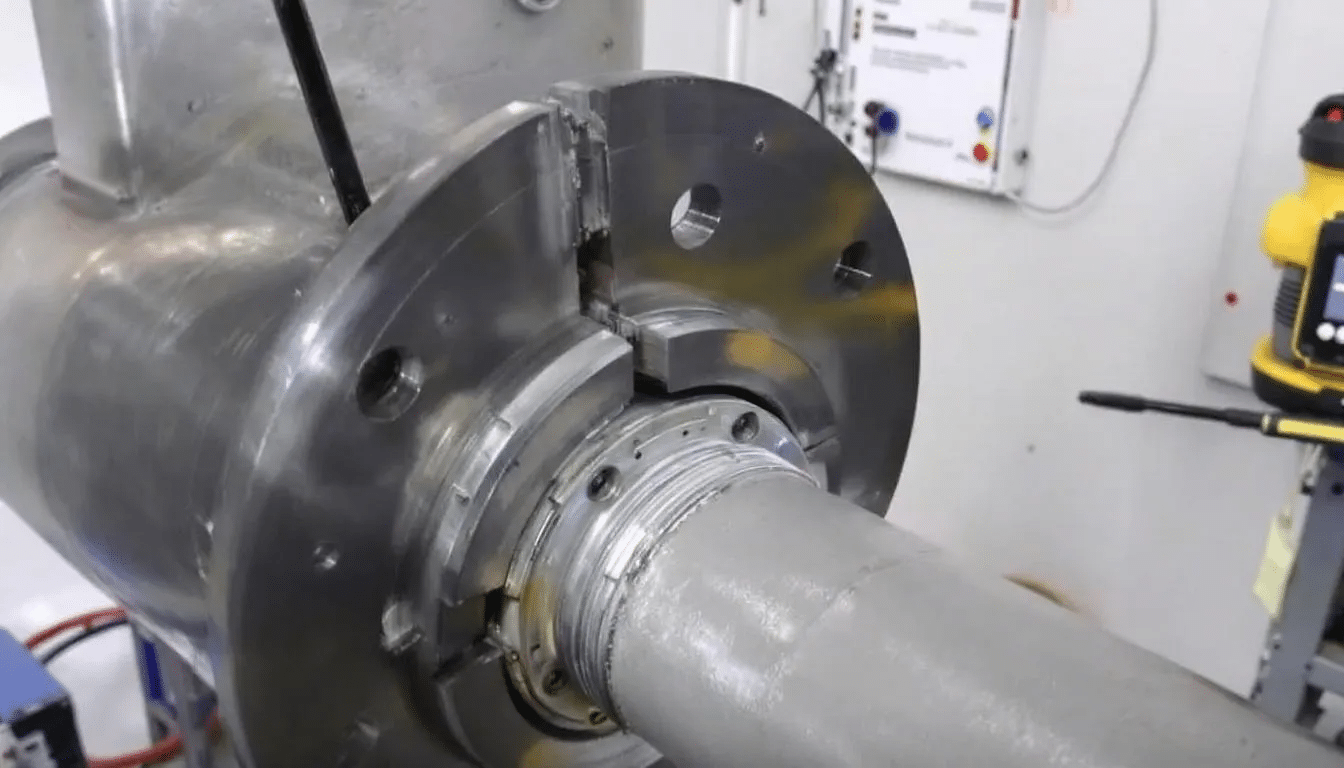

In the world of industrial applications, ensuring robust and reliable connections between pipes and other components is paramount. One such crucial component is the stainless steel 410 slip on flange. This versatile and durable flange is widely used across various sectors, including mechanical engineering, construction, and industrial projects. In this blog post, we’ll explore the significance, manufacturing process, and benefits of using stainless steel 410 slip on flanges, particularly those manufactured by Sachiya Steel International Private Limited, India’s leading manufacturer.

Specification Table of Stainless Steel 410 Slip On Flanges

|

Specification |

Details |

|---|---|

|

Material |

Stainless Steel 410 |

|

Type |

Slip On Flange |

|

Standards |

ASTM A182, ASME SA182 |

|

Dimensions |

ANSI/ASME B16.5, DIN, EN1092, JIS B2220 |

|

Sizes |

1/2″ to 24″ (DN 15 to DN 600) |

|

Pressure Rating |

Class 150, 300, 600, 900, 1500, 2500 |

|

Face Type |

RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) |

|

Connection |

Welded to Pipes |

|

Surface Treatment |

Rust-Proof Oil, Black Oil, Anti-Rust Paint, Galvanized |

|

Applications |

Mechanical Engineering, Construction, Industrial Projects |

This comprehensive specification table provides an authoritative summary of the key attributes that define the stainless steel 410 slip on flanges, ensuring you have all the essential details to make informed decisions for your industrial needs.

The Significance of Stainless Steel 410 in Flange Manufacture

Why Stainless Steel 410?

Stainless steel 410 is a martensitic stainless steel, known for its high strength and corrosion resistance. These properties make it an ideal material for manufacturing flanges, which need to withstand harsh environments and high pressure.

Superior Corrosion Resistance

The ability of stainless steel 410 to resist oxidation and corrosion is one of its standout features. This makes it a preferred choice for flanges used in chemical plants, refineries, and marine applications, where exposure to corrosive substances is common.

Strength and Durability

Beyond its corrosion resistance, stainless steel 410 offers excellent mechanical properties. It provides high tensile strength and toughness, ensuring that the flanges can handle significant stress and strain without deforming or breaking.

Stainless Steel 410 Slip On Flanges Price List

To aid in budgeting and procurement planning, we’ve provided a detailed price list for stainless steel 410 slip on flanges in both INR and USD. Please find the comprehensive pricing details for various sizes and pressure ratings below:

|

Size (Inch) |

Pressure Rating |

Price (INR) |

Price (USD) |

|---|---|---|---|

|

1/2″ |

Class 150 |

₹250 |

$3.50 |

|

1/2″ |

Class 300 |

₹300 |

$4.20 |

|

1/2″ |

Class 600 |

₹350 |

$4.90 |

|

1/2″ |

Class 900 |

₹400 |

$5.60 |

|

1/2″ |

Class 1500 |

₹450 |

$6.30 |

|

1/2″ |

Class 2500 |

₹500 |

$7.00 |

|

1″ |

Class 150 |

₹400 |

$5.60 |

|

1″ |

Class 300 |

₹450 |

$6.30 |

|

1″ |

Class 600 |

₹500 |

$7.00 |

|

1″ |

Class 900 |

₹550 |

$7.70 |

|

1″ |

Class 1500 |

₹600 |

$8.40 |

|

1″ |

Class 2500 |

₹650 |

$9.10 |

|

2″ |

Class 150 |

₹700 |

$9.80 |

|

2″ |

Class 300 |

₹750 |

$10.50 |

|

2″ |

Class 600 |

₹800 |

$11.20 |

|

2″ |

Class 900 |

₹850 |

$12.00 |

|

2″ |

Class 1500 |

₹900 |

$12.60 |

|

2″ |

Class 2500 |

₹950 |

$13.30 |

|

3″ |

Class 150 |

₹1,200 |

$16.80 |

|

3″ |

Class 300 |

₹1,300 |

$18.20 |

|

3″ |

Class 600 |

₹1,400 |

$19.60 |

|

3″ |

Class 900 |

₹1,500 |

$21.00 |

|

3″ |

Class 1500 |

₹1,600 |

$22.40 |

|

3″ |

Class 2500 |

₹1,700 |

$23.80 |

|

4″ |

Class 150 |

₹1,800 |

$25.20 |

|

4″ |

Class 300 |

₹2,000 |

$28.00 |

|

4″ |

Class 600 |

₹2,200 |

$30.80 |

|

4″ |

Class 900 |

₹2,400 |

$33.60 |

|

4″ |

Class 1500 |

₹2,600 |

$36.40 |

|

4″ |

Class 2500 |

₹2,800 |

$39.20 |

|

6″ |

Class 150 |

₹2,500 |

$35.00 |

|

6″ |

Class 300 |

₹2,800 |

$39.20 |

|

6″ |

Class 600 |

₹3,100 |

$43.40 |

|

6″ |

Class 900 |

₹3,400 |

$47.60 |

|

6″ |

Class 1500 |

₹3,700 |

$51.80 |

|

6″ |

Class 2500 |

₹4,000 |

$56.00 |

|

8″ |

Class 150 |

₹3,800 |

$53.20 |

|

8″ |

Class 300 |

₹4,200 |

$58.80 |

|

8″ |

Class 600 |

₹4,600 |

$64.40 |

|

8″ |

Class 900 |

₹5,000 |

$70.00 |

|

8″ |

Class 1500 |

₹5,400 |

$75.60 |

|

8″ |

Class 2500 |

₹5,800 |

$81.20 |

|

10″ |

Class 150 |

₹6,800 |

$95.20 |

|

10″ |

Class 300 |

₹7,500 |

$105.00 |

|

10″ |

Class 600 |

₹8,200 |

$114.80 |

|

10″ |

Class 900 |

₹8,900 |

$124.60 |

|

10″ |

Class 1500 |

₹9,600 |

$134.40 |

|

10″ |

Class 2500 |

₹10,300 |

$144.20 |

|

12″ |

Class 150 |

₹9,900 |

$138.60 |

|

12″ |

Class 300 |

₹10,800 |

$151.20 |

|

12″ |

Class 600 |

₹11,700 |

$163.80 |

|

12″ |

Class 900 |

₹12,600 |

$176.40 |

|

12″ |

Class 1500 |

₹13,500 |

$189.00 |

|

12″ |

Class 2500 |

₹14,400 |

$201.60 |

|

14″ |

Class 150 |

₹12,400 |

$173.60 |

|

14″ |

Class 300 |

₹13,500 |

$189.00 |

|

14″ |

Class 600 |

₹14,600 |

$204.40 |

|

14″ |

Class 900 |

₹15,700 |

$219.80 |

|

14″ |

Class 1500 |

₹16,800 |

$235.20 |

|

14″ |

Class 2500 |

₹17,900 |

$250.60 |

|

16″ |

Class 150 |

₹14,800 |

$207.20 |

Understanding the Manufacturing Process at Sachiya Steel International Private Limited

Raw Material Selection

At Sachiya Steel International Private Limited, the manufacturing process begins with the careful selection of raw materials. High-quality stainless steel 410 is sourced from reputable suppliers to ensure the end product meets stringent quality standards.

Precision Engineering

The selected stainless steel is then subjected to precision engineering processes. Advanced machinery and skilled technicians work together to shape and form the steel into slip on flanges. This involves various stages, including cutting, forging, and machining, to achieve the desired dimensions and specifications.

Heat Treatment and Finishing

To enhance the mechanical properties and durability of the flanges, heat treatment processes are employed. This includes annealing and tempering, which improve the steel’s hardness and strength. Finally, the flanges undergo surface finishing to ensure a smooth and polished appearance.

Chemical Properties of Stainless Steel 410 Slip On Flanges

|

Element |

Composition (%) |

|---|---|

|

Carbon (C) |

0.15 max |

|

Manganese (Mn) |

1.00 max |

|

Phosphorus (P) |

0.040 max |

|

Sulfur (S) |

0.030 max |

|

Silicon (Si) |

1.00 max |

|

Chromium (Cr) |

11.50 – 13.50 |

|

Nickel (Ni) |

0.75 max |

|

Iron (Fe) |

Balance |

Mechanical Properties of Stainless Steel 410 Slip On Flanges

|

Property |

Value |

|---|---|

|

Tensile Strength |

450 – 700 MPa |

|

Yield Strength |

205 MPa min |

|

Elongation (in 50mm) |

20% min |

|

Hardness |

22 HRC max (Rockwell Hardness) |

|

Impact Energy (Charpy V-notch) |

20 J min at room temperature |

Quality Control Measures and Certifications

Rigorous Testing Procedures

Quality control is a top priority at Sachiya Steel International Private Limited. Each stainless steel 410 slip on flange undergoes rigorous testing procedures to verify its compliance with international standards. This includes tests for mechanical properties, dimensional accuracy, and corrosion resistance.

Certifications and Standards

Sachiya Steel International Private Limited holds various certifications that attest to the quality of their products. These include ISO 9001, CE, and ASTM certifications, among others. Adhering to these standards ensures that customers receive flanges that meet or exceed industry expectations.

Customer Satisfaction

The company also places a strong emphasis on customer satisfaction. Feedback from clients is regularly sought and incorporated into the quality control process. This continuous improvement approach helps maintain high standards and build long-term relationships with customers.

Dimension Chart for Stainless Steel 410 Slip On Flanges

The following dimension chart provides critical measurements for stainless steel 410 slip on flanges, ensuring compatibility and proper fitment across diverse applications.

|

Size (Inches) |

Class |

Outside Diameter (OD) (mm) |

Inside Diameter (ID) (mm) |

Bolt Circle Diameter (BCD) (mm) |

Number of Bolts |

Bolt Hole Diameter (BHD) (mm) |

Flange Thickness (T) (mm) |

|---|---|---|---|---|---|---|---|

|

1/2″ |

150 |

89 |

15.8 |

60.5 |

4 |

15.9 |

12.7 |

|

1/2″ |

300 |

95 |

15.8 |

66.5 |

4 |

15.9 |

14.3 |

|

1/2″ |

600 |

95 |

15.8 |

66.5 |

4 |

15.9 |

22.2 |

|

1/2″ |

900 |

105 |

15.8 |

69.9 |

4 |

19.1 |

28.6 |

|

1/2″ |

1500 |

105 |

15.8 |

69.9 |

4 |

19.1 |

33.3 |

|

1/2″ |

2500 |

108 |

15.8 |

73.0 |

4 |

19.1 |

44.5 |

|

1″ |

150 |

114 |

22.9 |

77.7 |

4 |

15.9 |

14.3 |

|

1″ |

300 |

124 |

22.9 |

86.0 |

4 |

19.1 |

16.7 |

|

1″ |

600 |

127 |

22.9 |

88.9 |

4 |

19.1 |

23.9 |

|

1″ |

900 |

136 |

22.9 |

92.1 |

4 |

22.2 |

28.6 |

|

1″ |

1500 |

136 |

22.9 |

92.1 |

4 |

22.2 |

33.3 |

|

1″ |

2500 |

141 |

22.9 |

98.4 |

4 |

22.2 |

47.6 |

|

2″ |

150 |

152 |

50.8 |

120.7 |

4 |

19.1 |

15.9 |

|

2″ |

300 |

165 |

50.8 |

127.0 |

8 |

19.1 |

20.7 |

|

2″ |

600 |

171 |

50.8 |

133.4 |

8 |

19.1 |

27.7 |

|

2″ |

900 |

197 |

50.8 |

146.1 |

8 |

22.2 |

36.6 |

|

2″ |

1500 |

197 |

50.8 |

146.1 |

8 |

22.2 |

41.3 |

|

2″ |

2500 |

216 |

50.8 |

165.1 |

8 |

25.4 |

52.4 |

|

3″ |

150 |

190 |

76.2 |

152.4 |

4 |

19.1 |

17.5 |

|

3″ |

300 |

210 |

76.2 |

168.3 |

8 |

22.2 |

23.9 |

|

3″ |

600 |

216 |

76.2 |

171.5 |

8 |

22.2 |

31.8 |

|

3″ |

900 |

241 |

76.2 |

182.4 |

8 |

25.4 |

41.3 |

|

3″ |

1500 |

254 |

76.2 |

190.5 |

8 |

25.4 |

46.0 |

|

3″ |

2500 |

276 |

76.2 |

203.2 |

8 |

28.4 |

57.2 |

|

4″ |

150 |

229 |

101.6 |

190.5 |

8 |

19.1 |

19.1 |

|

4″ |

300 |

254 |

101.6 |

200.2 |

8 |

22.2 |

23.9 |

|

4″ |

600 |

268 |

101.6 |

215.9 |

8 |

22.2 |

33.3 |

|

4″ |

900 |

292 |

101.6 |

236.6 |

8 |

25.4 |

44.5 |

|

4″ |

1500 |

305 |

101.6 |

244.5 |

8 |

25.4 |

50.8 |

|

4″ |

2500 |

337 |

101.6 |

260.4 |

8 |

28.4 |

63.5 |

|

6″ |

150 |

279 |

152.4 |

241.3 |

8 |

22.2 |

20.7 |

|

6″ |

300 |

318 |

152.4 |

269.9 |

12 |

22.2 |

27.0 |

|

6″ |

Benefits of Using Stainless Steel 410 Slip On Flanges in Industrial Applications

Versatility and Adaptability

Stainless steel 410 slip on flanges are incredibly versatile and can be used in a wide range of industrial applications. Whether in chemical processing plants, oil refineries, or construction projects, these flanges provide reliable and leak-proof connections.

Cost-Effective Solution

The longevity and durability of stainless steel 410 slip on flanges make them a cost-effective solution. They require minimal maintenance and have a longer service life compared to other materials, reducing the need for frequent replacements and associated costs.

Enhanced Safety

Using high-quality slip on flanges enhances the safety of industrial operations. Their robust construction and resistance to wear and tear minimize the risk of leaks and failures, ensuring smooth and uninterrupted processes.

Case Studies and Testimonials from Satisfied Customers

Real-World Applications

Many industries have benefited from using stainless steel 410 slip on flanges from Sachiya Steel International Private Limited. For instance, a major chemical plant reported a significant reduction in maintenance costs and downtime after switching to these flanges.

Customer Testimonials

One satisfied customer, a leading construction company, praised the durability and reliability of the flanges. “We have been using Sachiya Steel’s stainless steel 410 slip on flanges for over a year now, and they have exceeded our expectations in terms of performance and longevity,” they said.

Industry Recognition

Sachiya Steel International Private Limited has also received recognition in the industry for their commitment to quality and customer satisfaction. Their products are widely regarded as some of the best in the market, making them a trusted choice for industrial buyers.

Project Reference Table

The following table highlights key projects where Sachiya Steel International Private Limited’s stainless steel 410 slip on flanges were utilized. Each project showcases the versatility, durability, and high performance of these products in various industrial applications.

|

Year |

Project Name |

Industry |

Location |

Description |

|---|---|---|---|---|

|

2019 |

Greenfield Chemical Plant Expansion |

Chemical Processing |

Texas, USA |

Supplied SS 410 slip on flanges for the expansion and modernization of chemical processing units. Expected to improve efficiency and reduce maintenance costs. |

|

2020 |

Offshore Oil Platform Renovation |

Oil & Gas |

North Sea |

Provided corrosion-resistant flanges to withstand harsh offshore conditions, ensuring reliable connections and safety. |

|

2021 |

Urban Infrastructure Development |

Construction |

Dubai, UAE |

Delivered durable flanges for key structural components in large-scale urban infrastructure projects. |

|

2022 |

Renewable Energy Wind Farm |

Renewable Energy |

Scotland |

Supplied flanges for wind turbine installation, contributing to a sustainable and eco-friendly energy solution. |

|

2023 |

High-Pressure Pipeline Project |

Petrochemical |

Saudi Arabia |

Provided high-performance flanges for high-pressure pipelines, ensuring secure and leak-proof connections in demanding applications. |

These references underscore Sachiya Steel International Private Limited’s commitment to delivering high-quality products that meet client requirements across various sectors.

How to Source and Order Stainless Steel 410 Slip On Flanges

Easy Ordering Process

Sourcing stainless steel 410 slip on flanges from Sachiya Steel International Private Limited is a straightforward process. Customers can visit the company’s website and browse through their extensive product catalog.

Customization Options

The company offers customization options to meet specific project requirements. Whether you need flanges with unique dimensions or additional features, Sachiya Steel can accommodate your needs.

Customer Support

For any queries or assistance, the company’s customer support team is readily available. They provide prompt and helpful responses, ensuring a smooth and hassle-free purchasing experience.

Export Countries List

Below is a comprehensive list of countries where Sachiya Steel International Private Limited supplies stainless steel 410 slip on flanges, excluding India. This extensive reach underscores our global presence and commitment to quality.

|

Export Countries |

|---|

|

United States |

|

Canada |

|

United Kingdom |

|

Germany |

|

France |

|

Italy |

|

Australia |

|

Japan |

|

South Korea |

|

Singapore |

|

United Arab Emirates |

|

Saudi Arabia |

|

Brazil |

|

South Africa |

|

Mexico |

|

Indonesia |

|

Malaysia |

|

Norway |

|

Netherlands |

|

Turkey |

This wide distribution network ensures that clients worldwide can access high-quality stainless steel 410 slip on flanges efficiently and reliably.

Conclusion The Future of Stainless Steel 410 Slip On Flanges

Continued Innovation

The future of stainless steel 410 slip on flanges looks promising, with ongoing advancements in manufacturing technologies and materials. Sachiya Steel International Private Limited continues to invest in research and development to deliver even better products to their customers.

Growing Demand

With the increasing demand for high-quality and reliable industrial components, stainless steel 410 slip on flanges will remain a crucial element in various industries. Their versatility, durability, and cost-effectiveness make them an indispensable part of modern industrial applications.

Commitment to Excellence

Sachiya Steel International Private Limited remains committed to providing top-notch products and services. Their dedication to quality, customer satisfaction, and continuous improvement ensures that they stay at the forefront of the industry.

Call to Action

Discover the difference that high-quality stainless steel 410 slip on flanges can make in your industrial projects. Visit Sachiya Steel International Private Limited website today to learn more about their products and place your order. Join the ranks of satisfied customers who trust Sachiya Steel for all their flange needs.

Stainless Steel 410 Slip On Flange

In the world of industrial applications, ensuring robust and reliable connections between pipes and other components is paramount. One such crucial component is the stainless steel 410 slip on flange. This versatile and durable flange is widely used across various sectors, including mechanical engineering, construction, and industrial projects. In this blog post, we'll explore the significance, manufacturing process, and benefits of using stainless steel 410 slip on flanges, particularly those manufactured by Sachiya Steel International Private Limited, India's leading manufacturer.

Product Brand: Sachiya Steel International Private Limited

Product Currency: INR

Product Price: 120

Price Valid Until: 2025-06-30

Product In-Stock: InStock

5