MS ERW Pipe Manufacturers In Benin

MS ERW pipes play an essential part in industrial steel products, thanks to their versatility, durability, and cost-effectiveness. Used across sectors ranging from construction and infrastructure to automotive and agriculture. This comprehensive guide seeks to explore all aspects of MS ERW pipes from their manufacturing process, chemical and mechanical properties, standards compliance compliance applications as well as leading manufacturers such as Sachiya Steel International Private Limited.

Introduction to MS ERW Pipes

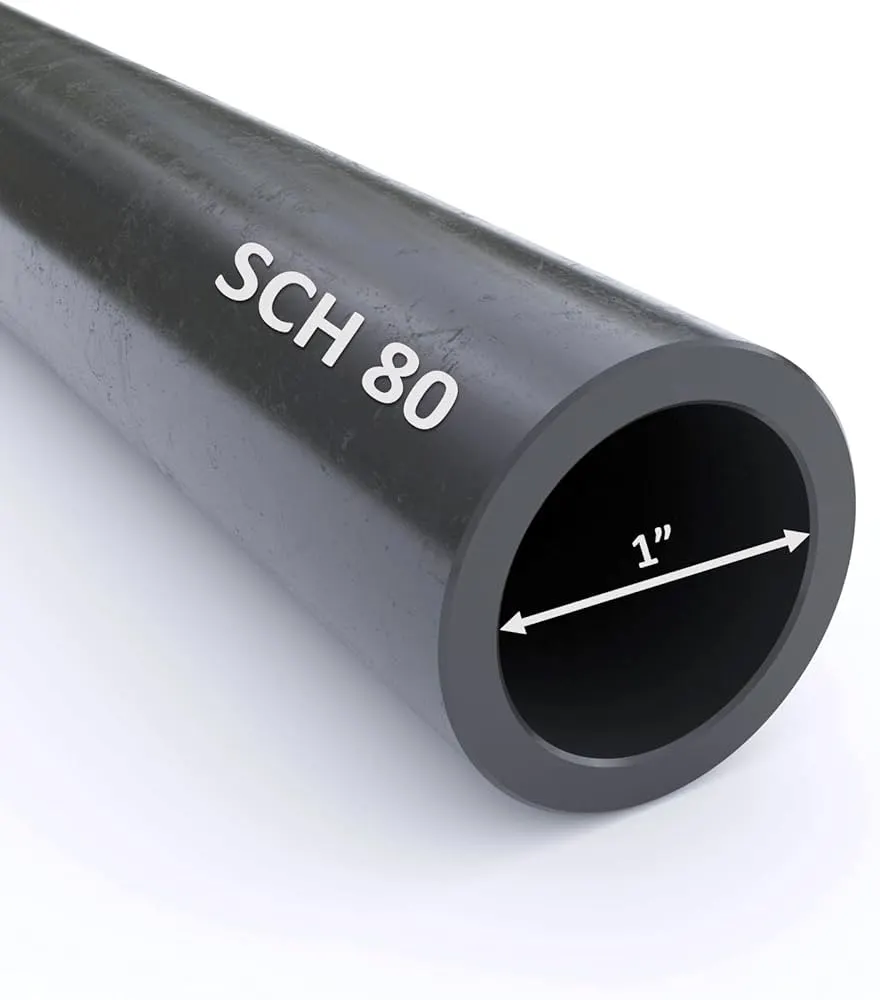

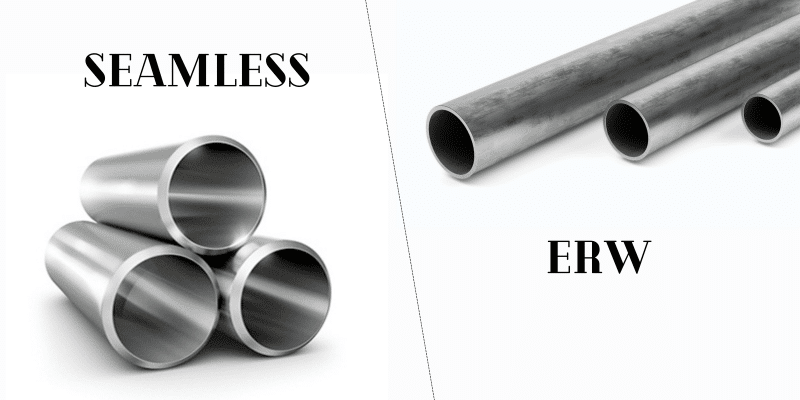

MS ERW pipes are constructed using low-carbon (mild) steel strips which are cold formed into cylindrical shapes before being longitudinally welded using electric resistance welding technology, producing uniform wall thickness and diameter without gaps between wall layers, making these ideal for conveying fluids under varied pressure conditions. Their popularity among various industries stems from being affordable, easy to install and long lasting – qualities which make MS ERW pipes highly valued products.

Manufacturing Process of MS ERW Pipes

The production process for MS ERW pipes includes several steps.

- Raw Material Selection: High-grade mild steel strips are selected based on their chemical and mechanical properties, usually to standards such as ASTM A36 or IS 1239 or equivalent.

- Forming: Cold-formed steel strips are cold-formed into cylindrical forms using rollers, which ensure that their edges are aligned for welding purposes.

- Welding: Electric Resistance Welding (ERW) is used to join together longitudinal edges of formed strips using electric current, heating them until they fuse without filler material and are then normalized to release any residual stresses in the seam.

- Sizing and Straightening: After being welded into place, welded pipes require both sizing to achieve their desired dimensions and straightening with rollers to meet straightness tolerance requirements.

- Cutting and Testing: After cutting pipes to their specified lengths, each one undergoes rigorous tests such as hydrostatic testing, nondestructive (such as ultrasonic testing), and dimensional inspection to ensure it satisfies quality standards. Testing typically includes hydrostatic pressure testing, non-destructive (such as ultrasonic testing), and dimensional inspection.

Chemical Composition of MS ERW Pipes

The chemical composition of MS ERW pipes typically includes the following elements:

Carbon (C): Typically less than 0.25%.

Manganese (Mn): Usually between 0.60% to 1.50%.

Phosphorus (P): Maximum 0.040%.

Sulfur (S): Maximum 0.040%.

The exact composition may vary depending on the standards and specifications required by the end-user or application.

Mechanical Properties of MS ERW Pipes

The mechanical properties of MS ERW pipes are crucial for their performance in various applications. These properties are tested in accordance with relevant standards such as ASTM, IS, or equivalent:

Tensile Strength: Typically ranging from 330 MPa to 450 MPa.

Yield Strength: Generally around 210 MPa to 360 MPa.

Elongation: Usually 20% to 25%.

Hardness: Often specified in terms of Rockwell hardness (HRB or HRC).

The mechanical properties ensure that MS ERW pipes can withstand the stresses imposed during installation, operation, and maintenance in different environments.

Standards and Specifications

Sachiya Steel International MS ERW pipes manufactured by reputable companies such as Sachiya Steel International meet international standards such as:

ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped Zinc-Coated Welded and Seamless Pipe. IS 1239 (Part 1): Mild Steel Tubes Tubulars and Other Wrought Steel Fittings Specification.

These standards ensure that pipes meet dimensional, mechanical, and chemical specifications suitable for their intended uses.

Applications of MS ERW Pipes

MS ERW pipes find extensive applications across various industries and sectors:

- Construction: Used in structural applications such as columns, beams, and purlins.

- Infrastructure: Suitable for water pipelines, drainage systems, and sewage lines.

- Automotive: Utilized in exhaust systems and chassis components.

- Oil and Gas: Used for conveying petroleum and natural gas.

- Agriculture: Employed in irrigation systems and sprinkler pipes.

- General Engineering: Used in the manufacture of furniture, scaffolding, and fencing.

The versatility of MS ERW pipes makes them indispensable in modern infrastructure development and industrial applications.

Leading Manufacturer: Sachiya Steel International Private Limited

Sachiya Steel International Private Limited of India is an award-winning manufacturer and supplier of MS ERW pipes. Recognized for their commitment to quality and customer satisfaction, Sachiya Steel offers an expansive selection of MS ERW pipes in various sizes, thicknesses, specifications and lengths; their manufacturing facilities boast state-of-the-art machinery which guarantees consistency quality precision with every product they manufacture.

Advantages of Choosing Sachiya Steel International

- Quality Assurance: Stringent quality control measures ensure that each MS ERW pipe meets international standards and customer specifications.

- Customization: Sachiya Steel International offers customization options for MS ERW pipes, including dimensions, coatings, and end finishes to meet specific project requirements.

- Global Reach: With a strong distribution network, Sachiya Steel International serves clients not only in India but also in Benin and other global markets, ensuring timely delivery and support.

- Commitment to Sustainability: Sachiya Steel International prioritizes sustainable manufacturing practices, minimizing environmental impact and promoting eco-friendly solutions.

MS ERW pipes produced by Sachiya Steel International Private Limited play an essential part in the infrastructure and industrial development of countries such as Benin. Due to their cost-effectiveness, durability, and straightforward installation process they are an ideal choice across various fields: from construction to oil and gas exploration or automotive use; MS ERW pipes ensure performance with reliability.

As industries expand and change, demand for high-quality MS ERW pipes will only continue to increase. Sachiya Steel International stands ready to meet this demand with innovative solutions and its unwavering dedication to excellence. Businesses in Benin seeking MS ERW pipes should partner with an established manufacturer for maximum reliability and peace of mind.

Make your projects successful with MS ERW pipes from manufacturers who prioritize quality and customer satisfaction, like Sachiya Steel International. Their wide variety of MS ERW pipes is sure to meet all your specific requirements and help advance success in any industry. Contact Sachiya Steel International now and explore how their range can meet those criteria – they could just be what’s missing from your success in business!

MS ERW PIPES

MS ERW pipes play an essential part in industrial steel products, thanks to their versatility, durability, and cost-effectiveness. Used across sectors ranging from construction and infrastructure to automotive and agriculture. This comprehensive guide seeks to explore all aspects of MS ERW pipes from their manufacturing process, chemical and mechanical properties, standards compliance compliance applications as well as leading manufacturers such as Sachiya Steel International Private Limited.

Product Brand: Sachiya Steel International Private Limited

Product Currency: INR

Product Price: 80

Price Valid Until: 2025-06-21

Product In-Stock: InStock

5