ASTM A106 GR B PIPE SPECIFICATION | ASTM SA106 GR B CARBON STEEL PIPE

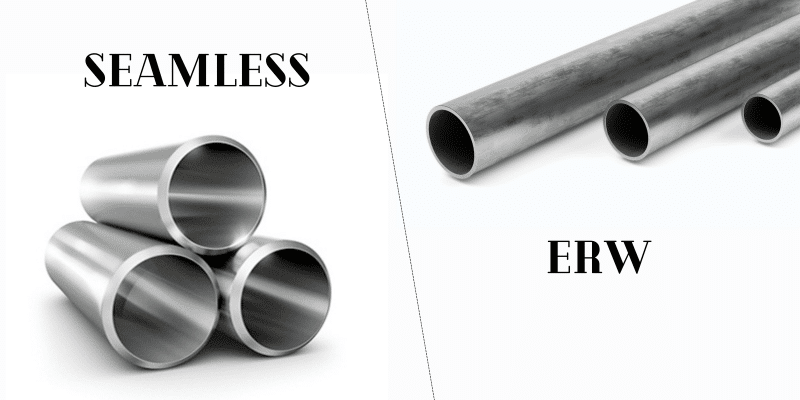

ASTM A106 seamless pipes, often recognized as ASME SA106 pipes, are typically seamless in their build and primarily designed for the conveyance of gases and liquids from one place to another. These pipes are particularly well-suited for high-temperature applications and are capable of withstanding substantial pressure. They are crafted in compliance with the dimensional standards outlined in ANSI B36.10 / ASME B36.10. Among the various grades available, ASTM A106 Grade B stands out as the most commonly employed pipe. This grade enjoys widespread preference among clients, owing to its cost-effectiveness and ready availability worldwide.

SA106 GR B pipes (commonly referred to as ASTM A106 GR B pipes) are seamless carbon steel pipes renowned for their exceptional performance in high temperature environments, from oil and gas extraction to power generation. Their ability to withstand elevated temperatures and pressures makes these piping essential in many industries from oil & gas extraction to power generation – Sachiya Steel International Pvt. Ltd is proud to be a reliable ASTM A106 Gr B Pipe manufacturer offering reliable solutions for critical applications.

If you’re looking for premium high-temperature pipes then look no further than ASTM A106 Grade B (A106 Gr B) or SA Grade B (SA106 Gr B). Famous for their extraordinary longevity and dependability, ASTM A106 Grade B pipes are made to conform to the strictest industry standards. Our inventory offers a broad assortment of Grade B A106 pipes that are designed in accordance with ASTM specifications to provide high-quality performance in all kinds of applications. No matter if you require ASTM pipes 106 as well SA the 106 pipes of Grade B, we’ve got you covered.

Our pipes provide superior resistance to corrosion and high pressure. Be confident in the quality in ASTM A106 grade B pipe for projects because they always provide the strength and dependability required for industrial applications that require a high degree of precision. Select ASTM Grade B A106 to get an unidirectional solution that will meet and surpasses your expectations in high temperature conditions.

ASTM A106 GR B PIPE / SA106 GR B PIPE SPECIFICATION

| A106 Pipe Specification | A106 NPS 1/8 — 48 ANSI | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

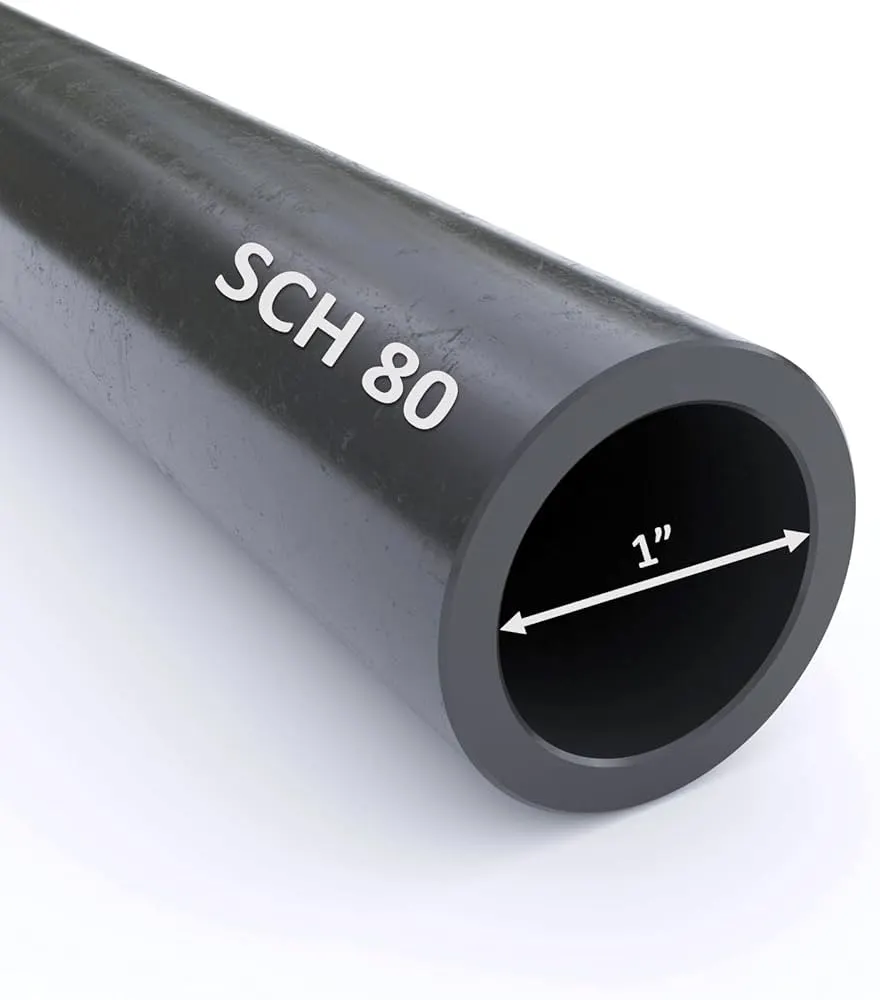

| A106 grade b pipe wall thickness available | (SCH5, SCH5S, SCH10, SCH10S, SCH20, SCH30, STD, SCH40, SCH40S, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS) Schedule 20 – Schedule XXS (heavier on request) up to 250 mm thk. |

||||||||||||

| ASME SA 106 Gr B Scope | Covers SEAMLESS carbon steel nominal wall pipe for high-temperature service, suitable for bending, flanging and similar forming operations.

NPS 1 1/2 and under may be either hot finished or cold drawn. NPS 2 and larger shall be hot finished unless otherwise specified. |

||||||||||||

| Kinds of Steel Permitted For For Pipe Material |

Killed Steel Open-hearth Electric-furnace Basic-oxygen |

||||||||||||

| ASTM A106 Grade C Pipe Hot-Dipped Galvanizing |

Not covered in specification. | ||||||||||||

| Permissible Variations in Wall Thickness |

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified. | ||||||||||||

| Tensile Requirements |

A106 Gr.B Seamless Pipe

|

||||||||||||

| Hydrostatic Testing | Inspection test pressures produce a stress in the pipe wall equal to 60% or specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS 3 and under and 2800 psifor the larger sizes. Pressure is maintained for not less than 5 seconds. | ||||||||||||

| Permissible Variations in Weights per Foot | Weight of any length shall not vary more than 10% over and 3.5% under that specified. NOTE — NPS 4 and smaller — weighed in lots. Larger sizes — by length |

||||||||||||

| Lengths | Lengths required shall be specified on order. No “jointers” permitted unless otherwise specified. If no definite lengths required, following practice applies: Single Random — 16′ – 22′. 5% may be 12′ – 16′ Double Random — Minimum length 22′, Minimum average 35′. 5% may be 16′ – 22′. |

||||||||||||

| Required Markings on Each Length | (On Tags attached to each Bundie in case of Bundled Pipe) Rolled Stamped or Stenciled (Mfgrs. option)

|

||||||||||||

| General Information | Unless otherwise specified, pipe furnished with plain ends. Purchaser may specify NDE Surface finish standards are outlined in specification. in lieu of hydrostatic test or neither |

Manufacturing Excellence

Sachiya Steel International Pvt. Ltd maintains only the highest standards when manufacturing ASTM A106 GR B pipes, using two primary processes for production: hot-finished and cold-drawn. In hot-finished production, pipes are heated to optimal temperatures before being carefully hand shaped before cold-drawing is used to achieve precise dimensions – our commitment to precision ensures each ASTM A106 GR B pipe surpasses rigorous quality benchmarks.

At Sachiya Steel International, we take pride in our extensive inventory of ASTM A106 pipes, which cater to a wide range of needs and specifications.

- Our pipe offerings encompass Grade B and Grade C, and they come in various sizes, starting from ¼” NPS and extending up to 24″ NPS. In response to our clients’ specific requirements, we’re also equipped to provide large-diameter pipes exceeding 24″ NPS.

- The thickness of our pipes varies, ranging from SCH 20 to SCH XXS, conforming to ANSI B36.10 / ASME B36.10 standards. What sets us apart is our flexibility in accommodating non-standard thicknesses that may not be readily available within the specified dimensional standards.

- When it comes to length, our pipes can be delivered in two options: single random lengths measuring 4 to 7 meters or double random lengths spanning 7 to 12 meters. Should our clients have precise length preferences, we’re more than willing to supply fixed-length pipes.

- Quality is paramount to us, and we ensure the integrity of our pipes by offering Mill test certificates compliant with EN 10204 3.1 and 3.2. Additionally, our pipes meet the Indian boiler requirements through IBR Form III certification.

- For clients with specific specifications, our pipes can be tailored to meet a range of additional requirements, including NACE MR0175, NACE MR0103, H2 Service, Wet H2S Service, AXN1, AXN2, AXN3, AXN4, UOP1, UOP2, NAC4, NAC6, and NAC7.

- To accommodate various inspection preferences, we are open to working with any Third-party inspection agency chosen by our clients, ensuring that our products meet their unique standards and expectations.

ASTM A106 GRADE B / SA106 GR B PIPE PRICE IN INDIA

| Size” | MSL Make | ISMT make | JSL Make |

|---|---|---|---|

| 1/2″ | 1,323.53 | 1,316.18 | 1,330.88 |

| 3/4″ | 1,102.94 | 1,095.59 | 1,110.29 |

| 1″ | 955.88 | 948.53 | 963.24 |

| 1.25″ | 911.76 | 904.41 | 919.12 |

| 1.5″ | 808.82 | 801.47 | 816.18 |

Please note: All Above Prices are USD $/Ton. All price applicable for SCH 40, SCH 60, SCH 80 & SCH XS Pipe

ASTM A106 Grade B Price In India

| 1-1/2IN SCH 160 A106 BLACK SEAMLESS PIPE | Price: $13.92 ft |

| 1-1/2IN SCH 40 A106B BLACK SEAMLESS PIPE | Price: $3.44 ft |

| 1-1/2IN SCH 80 A106B BLACK SEAMLESS PIPE | Price: $4.69 ft |

| 1-1/4IN SCH 40 A106 BLACK SEAMLESS PIPE | Price: $2.90 ft |

| 1/2IN SCH 160 BLACK SEAMLESS PIPE | Price: $5.67 ft |

| 1/2IN SCH 40 A106B BLACK SEAMLESS PIPE | Price: $3.95 ft |

| 1/2IN SCH 80 A106B SEAMLESS BLACK PIPE | Price: $2.22 ft |

| 10IN XH .500 WALL A106B SEAMLESS BLACK PIPE | Price: $100.19 ft |

| 12IN STD .375 WALL A106B BLACK SEAMLESS PIPE | Price: $101.02 ft |

| 12IN XH .500 WALL A106B SEAMLESS BLACK PIPE | Price: $120.10 ft |

| 14IN STD .375 A106-B BLACK SEAMLESS PIPE | Price: $100.80 ft |

| 14IN XH .500 WALL BLACK SEAMLESS PIPE A106B | Price: $142.90 ft |

S/A 106 SEAMLESS PIPE IS ONE OF OUR MOST POPULAR PRODUCTS. WE CARRY SCHEDULES 10 THROUGH 160, STD, XH, AND XXH.

Advantages of ASTM A106 GR B Pipes

Using ASTM A106 GR B pipes offers an array of advantages:

- Temperature Resilience: With a tolerance for temperatures up to 750°F, these pipes excel in hot environments.

- Corrosion Resistance: These pipes’ composition protects against corrosion in various settings.

- Robust Strength: Their mechanical properties ensure resilience under high stress and pressure conditions.

- Ease of Use: ASTM A106 GR B pipes are compatible with various welding and threading methods.

The ASTM A106 specification serves as the benchmark for carbon and alloy steel pipes. It outlines the specific requirements that such pipes must meet. Additionally, ASTM A530/A530M provides general prerequisites for specialized carbon and alloy steel pipes, ensuring they meet industry standards.

For assessing the quality of metal pipes and tubing, ASTM E213 prescribes the practice of ultrasonic examination. This method employs ultrasonic waves to detect any imperfections or irregularities within the material.

Eddy-current examination, as detailed in ASTM E309, is another crucial practice for assessing the integrity of steel tubular products. It uses magnetic saturation to identify potential defects or weaknesses in the material.

To further evaluate the quality of steel bars, billets, blooms, and forgings, ASTM E381 prescribes the macroetch testing method. This procedure involves etching the material’s surface to reveal any hidden flaws.

When dealing with ferromagnetic steel tubular products, ASTM E570 provides guidelines for conducting flux leakage examinations. This method helps in identifying issues within the material that might not be visible on the surface.

Finally, ASME B36.10M sets the dimensional standards for both seamless and welded pipes. These standards are crucial for ensuring that pipes fit and function as intended.

Tolerance in Outer Diameter as per ASTM A106

Outside Diameter at any point shall not vary from standard specified more than:

| NPS [DN Designator] | Over | Under | ||

| in. | mm | in. | mm | |

| 1/8 to 1-1/2 [6 to 40], incl | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1-1/2 to 4 [40 to 100], incl | 1/32 (0.031) | 0.8 | 1/32 (0.031) | 0.8 |

| Over 4 to 8 [100 to 200], incl | 1/16 (0.062) | 1.6 | 1/32 (0.031) | 0.8 |

| Over 8 to 18 [200 to 450], incl | 3/32 (0.093) | 2.4 | 1/32 (0.031) | 0.8 |

| Over 18 to 26 [450 to 650], incl | 1/8 (0.125) | 3.2 | 1/32 (0.031) | 0.8 |

| Over 26 to 34 [650 to 859], incl | 5/32 (0.156) | 4.0 | 1/32 (0.031) | 0.8 |

| Over 34 to 48 [850 to 1200], incl | 3/16 (0.187) | 4.8 | 1/32 (0.031) | 0.8 |

Hydrostatic Test

As part of our efforts to guarantee the quality of our pipes, we conduct hydrostatic tests on each pipe segment to verify there are no leaks through its walls. The hydro test exerts stress equivalent to 60% of its Specified Minimum Yield Strength (SMYS). For pipes up to 3″ NPS size, maximum allowable hydro test pressure should not exceed 2500 PSI while larger diameter pipes (above 3″) exceed this limit at 2800 PSI – this rigorous process ensures pipe integrity and safety.

Number of Tests Required for ASTM A106 grade b pipe

| NPS | On One Length From Each Lot of | |

|---|---|---|

| Tensile | 5 and smaller 6 and larger 200 or less |

400 or less 6 and larger 200 or less |

| Bonding | 2 and smaller | 400 or less |

| Flattening | 2 through 5 6 and over |

400 or less 200 or less |

A106 grade b seamless pipe Mechanical Tests Specified

A106 PIPE DIMENSIONS

| Standard | Permissible Variations in Outside Diameter | ||

|---|---|---|---|

| NPS” | OVER | UNDER | |

| ASTM A53-12 | 1-1/2 and less | 1/64” (0.015”) | 1/64” (0.015”) |

| ASTM A53-12 | 2 and over | 1% of OD | 1% of OD |

| ASTM A106-15 | 1/8 to 1-1/2 | 1/64” (0.015”) | 1/64” (0.015”) |

| ASTM A106-15 | Over 1-1/2 to 4 | 1/32” (0.031”) | 1/32” (0.031”) |

| ASTM A106-15 | Over 4 to 8 | 1/16” (0.062”) | 1/32” (0.031”) |

| ASTM A106-15 | Over 8 to 18 | 3/32” (0.093”) | 1/32” (0.031”) |

| ASTM A106-15 | Over 18 to 26 | 1/8” (0.125”) | 1/32” (0.031”) |

| ASTM A106-15 | Over 26 to 34 | 5/32” (0.156”) | 1/32” (0.031”) |

| ASTM A106-15 | Over 34 to 48 | 3/16” (0.187”) | 1/32” (0.031”) |

| A106 Pipe Fittings | A106 Carbon Steel Pipe Fittings, Elbows, Tees, Reducers |

|---|---|

| ASTM A106 Grade B Seamless Nipples | ASTM A106 Grade B Carbon Steel Seamless Nipples |

| A106 Pipe-Pipe Nipples-End Connections | Carbon Steel Pipe Nipples-End Connections for A106 Pipe |

| Fitting (weldolet) Material for A106 Gr. C Pipe | Fitting (weldolet) Material for A106 Gr. C Pipe |

| Weldolet on a106 pipe | 3000# Standard Weight Steel Weldolet |

| ASTM A106 B NACE MR0175 | NACE MR0175 standard includes ASTM A106 Grade B, A, and C. A106 pipe and related fittings which are made from the NACE material (complied with NACE MR 0175 or ISO 15156 standard). We call them NACE pipe, or NACE pipe fittings. |

| Applications of A106 Pipe | A106 Pipe are mainly used in refineries and plants when gasses or fluids are transported at high temperatures and pressures |

A106 PIPE MATERIAL

| A106 pipe Quantity | Feet, centimeters, or number of lengths | ||||

|---|---|---|---|---|---|

| Name of material | A106 Seamless or Welded Pipe | ||||

| A106 pipe Grade | Grade A, Grade B, or Grade C | ||||

| A106 pipe Manufacture | Hot-finished or cold-drawn | ||||

| A106 pipe Size | NPS or Outside Diameter and Schedule Number of Average Wall Thickness | ||||

| Special outside diameter tolerance pipe | |||||

| Inside diameter tolerance pipe, over 10 in ID | |||||

| A106 pipe Length | Specific or random | ||||

| Supplementary requirements | |||||

| Test Report Required | |||||

| Specification designation | |||||

| Hydrostatic test | |||||

| Special requirements | |||||

ASTM A 106 grade B Seamless Pressure Pipe

B) Unless otherwise specified by the purchaser, for each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

*ASME SA 106 grade B Seamless Pressure Pipe

B) For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.35 %.

ASTM A106 GRADE B PIPE EQUIVALENT

Get SA 106 Gr B Equivalent Properties and ASTM A106 Grade B Equivalent in below table.

| Former | New | |||

|---|---|---|---|---|

| Execution | Standard | Material | Standard | Material |

| Seamless | ASTM A106 | GRADE B | EN 10216-2 | P265GH |

| Seamless | ASTM A333 | GRADE 6 | EN 10216-4 | P265NL |

| Welded | API 5L | Grade B | EN 10208-2 | L245NB |

| Welded | API 5L | Grade X52 | EN 10208-2 | L360NB |

| Seamless | API 5L | Grade B | EN 10208-2 | L245NB |

| Seamless | API 5L | Grade X52 | EN 10208-2 | L360NB |

| ASTM A106 Grade B Pipe Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| ASTM A106 Grade B Seamless Pipe (Custom Sizes) | 1/2″ NB – 60″ NB | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Custom |

| ASTM A106 Grade B Welded Pipe (in Stock + Custom Sizes) | 1/2″ NB – 24″ NB | As per requirement | Custom |

| ASTM A106 Grade B ERW Pipe (Custom Sizes) | 1/2″ NB – 24″ NB | As per requirement | Custom |

| ASTM A106 Grade B SAW Pipe | 16″ NB – 100″ NB | As per requirement | Custom |

OTHER TYPES OF ASTM A106 GR.B CARBON STEEL PIPES

| ASTM A106 Gr.B Seamless Pipe | ASTM A106 Welded Pipe |

| ASTM CS Gr.B Seamless Pipes | Grade B A106 Welded Pipe |

| ASTM A106 ERW CS Pipes | A106 ERW CS Pipe |

| A106 erw pipe | A106 carbon steel pipe |

| A106 grade b pipe | ASTM A106 grade b |

| A106 Carbon Steel Welded Pipe | ASTM A106 Seamless Pipe |

| A106 Carbon Steel Seamless Pipe | Grade B Carbon Steel ERW Pipe |

| ASTM A106 Gr.B CS Pipes | A106 gr b welded pipe |

| A106 grade b seamless pipe | ASTM A106 Gr B Sch 40 |

A106 PIPE SIZES

| NPS [DN Designator] | Over | Under | ||

|---|---|---|---|---|

| in. | mm | in. | mm | |

| 1/8 to 1-1/2 [6 to 40], incl | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1-1/2 to 4 [40 to 100], incl | 1/32 (0.031) | 0.8 | 1/32 (0.031) | 0.8 |

| Over 4 to 8 [100 to 200], incl | 1/16 (0.062) | 1.6 | 1/32 (0.031) | 0.8 |

| Over 8 to 18 [200 to 450], incl | 3/32 (0.093) | 2.4 | 1/32 (0.031) | 0.8 |

| Over 18 to 26 [450 to 650], incl | 1/8 (0.125) | 3.2 | 1/32 (0.031) | 0.8 |

| Over 26 to 34 [650 to 859], incl | 5/32 (0.156) | 4.0 | 1/32 (0.031) | 0.8 |

| Over 34 to 48 [850 to 1200], incl | 3/16 (0.187) | 4.8 | 1/32 (0.031) | 0.8 |

ASTM A106 GRADE B / SA106 GR B PIPE PRESSURE RATING

MAXIMUM WORKING PRESSURE OF ASTM A106 GRADE B PIPE AT TEMPERATURE 400°F

THE DIMENSIONS – OUTSIDE PIPE DIAMETERS AND WALL THICKNESSES ARE ACCORDING ANSI B36.10.

| Maximum Allowable Pressure (psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | Outside Diameter | Schedule | ||||||||||||

| (in) | (in) | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 | 100 | 120 | 140 | 160 | XXS |

| 1/4 | 0.54 | 7985 | 7985 | 10798 | 10798 | |||||||||

| 3/8 | 0.675 | 6606 | 6606 | 9147 | 9147 | |||||||||

| 1/2 | 0.84 | 6358 | 6358 | 8575 | 8575 | 10908 | 17150 | |||||||

| 3/4 | 1.05 | 5273 | 5273 | 7187 | 7187 | 10220 | 14373 | |||||||

| 1 | 1.315 | 4956 | 4956 | 6670 | 6670 | 9316 | 13340 | |||||||

| 1 1/4 | 1.66 | 4133 | 4133 | 5638 | 5638 | 7380 | 11276 | |||||||

| 1 1/2 | 1.9 | 3739 | 3739 | 5158 | 5158 | 7247 | 10316 | |||||||

| 2 | 2.375 | 3177 | 3177 | 4498 | 4498 | 7097 | 8995 | |||||||

| 2 1/2 | 2.875 | 3460 | 3460 | 4704 | 4704 | 6391 | 9408 | |||||||

| 3 | 3.5 | 3024 | 3024 | 4200 | 4200 | 6132 | 8400 | |||||||

| 3 1/2 | 4 | 2769 | 2769 | 3896 | 3896 | |||||||||

| 4 | 4.5 | 2581 | 2581 | 3670 | 3670 | 4769 | 5782 | 7339 | ||||||

| 5 | 5.563 | 2273 | 2273 | 3303 | 3303 | 4404 | 5505 | 6606 | ||||||

| 6 | 6.625 | 2071 | 2071 | 3195 | 3195 | 4157 | 5318 | 6390 | ||||||

| 8 | 8.625 | 1420 | 1574 | 1829 | 1829 | 2307 | 2841 | 2841 | 3375 | 4085 | 4613 | 5147 | 4971 | |

| 10 | 10.75 | 1140 | 1399 | 1664 | 1664 | 2279 | 2279 | 2708 | 3277 | 3847 | 4558 | 5128 | 4558 | |

| 12 | 12.75 | 961 | 1268 | 1441 | 1560 | 2160 | 1922 | 2644 | 3244 | 3843 | 4324 | 5042 | 3843 | |

| 14 | 14 | 875 | 1092 | 1313 | 1313 | 1533 | 2079 | 1750 | 2625 | 3283 | 3829 | 4375 | 4921 | |

| 16 | 16 | 766 | 956 | 1148 | 1148 | 1531 | 2009 | 1531 | 2585 | 3157 | 3733 | 4404 | 4882 | |

| 18 | 18 | 681 | 849 | 1192 | 1021 | 1530 | 2042 | 1361 | 2553 | 3147 | 3743 | 4252 | 4848 | |

| 20 | 20 | 613 | 919 | 1225 | 919 | 1455 | 1989 | 1225 | 2526 | 3138 | 3675 | 4288 | 4824 | |

| 22 | 22 | 557 | 835 | 1114 | 835 | 1949 | 1114 | 2506 | 3063 | 3619 | 4176 | 4733 | ||

| 24 | 24 | 510 | 766 | 1147 | 766 | 1405 | 1978 | 1021 | 2489 | 3126 | 3700 | 4210 | 4786 | |

| 30 | 30 | 510 | 817 | 1021 | 613 | 817 | ||||||||

| 32 | 32 | 478 | 766 | 957 | 574 | 1054 | ||||||||

| 34 | 34 | 450 | 721 | 901 | 540 | 992 | ||||||||

| 36 | 36 | 425 | 681 | 851 | 510 | 1021 | ||||||||

| 42 | 42 | 583 | 729 | 438 | 875 | |||||||||

- 1 in (inch) = 25.4 mm

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2) = 6.895×10-2 bar

WELDED AND SEAMLESS ASTM A106 GRADE B PIPE, ASTM A106 GRADE B MATERIAL, ASTM A106 PIPE, ASTM A 106 GR B PIPE, ASTM A106B PIPE

A106 GR B SCH 40, ASTM A106 GRADE B PIPE DIMENSIONS AND WEIGHTS SECTION MODULUS AND GALLONS CAPACITY PER LINEAR FOOT

| Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot | Standard to XXHY | Schedule Pipe # |

Section Modulus | Gallon Capacity Per Linear Foot |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 | STD | 40 | .0407 | .0158 |

| 0.147 | 0.546 | 1.09 | XHY | 80 | .0478 | .0122 | ||

| 0.188 | 0.464 | 1.31 | 160 | .0528 | .0088 | |||

| 0.294 | 0.252 | 1.72 | XXHY | .0577 | .0026 | |||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 | STD | 40 | .0705 | .0277 |

| 0.154 | 0.742 | 1.48 | XHY | 80 | .0853 | .0225 | ||

| 0.219 | 0.612 | 1.95 | 160 | .1006 | .0153 | |||

| 0.308 | 0.434 | 2.44 | XXHY | .1103 | .0077 | |||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 | STD | 40 | .1328 | .0449 |

| 0.179 | 0.957 | 2.17 | XHY | 80 | .1606 | .0374 | ||

| 0.250 | 0.815 | 2.85 | 160 | .1904 | .0271 | |||

| 0.358 | 0.599 | 3.66 | XXHY | .2136 | .0146 | |||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 | STD | 40 | .2346 | .0777 |

| 0.191 | 1.278 | 3.00 | XHY | 80 | .2913 | .0666 | ||

| 0.250 | 1.160 | 3.77 | 160 | .3421 | .0549 | |||

| 0.382 | 0.896 | 5.22 | .4110 | .0328 | ||||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 | STD | 40 | .3262 | .1058 |

| 0.200 | 1.500 | 3.63 | XHY | 80 | .4118 | .0918 | ||

| 0.281 | 1.338 | 4.86 | 160 | .5079 | .0730 | |||

| 0.400 | 1.100 | 6.41 | .5977 | .0494 | ||||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 | 10 | .4205 | .1898 | |

| 0.154 | 2.067 | 3.66 | STD | 40 | .5606 | .1743 | ||

| 0.218 | 1.939 | 5.03 | XHY | 80 | .7309 | .1534 | ||

| 0.250 | 1.875 | 5.68 | .8045 | .1434 | ||||

| 0.281 | 1.813 | 6.29 | .8666 | .1344 | ||||

| 0.344 | 1.687 | 7.47 | 160 | .9806 | .1161 | |||

| 0.436 | 1.503 | 9.04 | XXHY | 1.1043 | .0922 | |||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 | 10 | .6870 | .2833 | |

| 0.203 | 2.469 | 5.80 | STD. | 40 | 1.0640 | .2487 | ||

| 0.216 | 2.443 | 6.14 | 1.1169 | .2435 | ||||

| 0.250 | 2.375 | 7.02 | 1.2468 | .2301 | ||||

| 0.276 | 2.323 | 7.67 | XHY | 80 | 1.3386 | .2202 | ||

| 0.375 | 2.125 | 10.02 | 160 | 1.6371 | .1842 | |||

| 0.552 | 1.771 | 13.71 | XXXHY | 1.9971 | .1280 | |||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 | 1.0411 | .4336 | ||

| 0.156 | 3.188 | 5.58 | 1.3122 | .4147 | ||||

| 0.172 | 3.156 | 6.12 | 1.4265 | .4064 | ||||

| 0.188 | 3.124 | 6.66 | 1.5342 | .3984 | ||||

| 0.216 | 3.068 | 7.58 | STD. | 40 | 1.7241 | .3840 | ||

| 0.250 | 3.000 | 8.69 | 1.9372 | .3672 | ||||

| 0.281 | 2.938 | 9.67 | 2.1207 | .3521 | ||||

| 0.300 | 2.900 | 10.26 | XHY | 80 | 2.2253 | .3431 | ||

| 0.438 | 2.624 | 14.34 | 160 | 2.8774 | .2811 | |||

| 0.600 | 2.300 | 18.6 | XXHY | 3.4243 | .2158 | |||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 | 10 | 1.3776 | .5768 | |

| 0.226 | 3.548 | 9.12 | STD. | 140 | 2.3939 | .5136 | ||

| 0.250 | 3.500 | 10.02 | 2.6001 | .4998 | ||||

| 0.281 | 3.438 | 11.17 | 2.8562 | .4821 | ||||

| 0.318 | 3.364 | 12.52 | XHY | 80 | 3.1400 | .4617 | ||

| 0.636 | 2..728 | 22.87 | XXHY | 4.8795 | .3085 | |||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 | 10 | 1.7612 | .7404 | |

| 0.156 | 4.188 | 7.24 | 2.2354 | .7156 | ||||

| 0.188 | 4.124 | 8.67 | 2.6296 | .6942 | ||||

| 0.203 | 4.094 | 9.32 | 2.8173 | .6838 | ||||

| 0.219 | 4.062 | 10.02 | 3.0184 | .6725 | ||||

| 0.237 | 4.026 | 10.80 | STD. | 40 | 3.2145 | .6613 | ||

| 0.250 | 4.000 | 11.36 | 3.3611 | .6528 | ||||

| 0.281 | 3.938 | 12.67 | 60 | 3.7021 | .6326 | |||

| 0.312 | 3.876 | 13.97 | 4.0273 | .6126 | ||||

| 0.337 | 3.826 | 15.00 | XHY | 80 | 4.2713 | .5972 | ||

| 0.438 | 3.624 | 19.02 | 120 | 5.1790 | .5361 | |||

| 0.531 | 3.438 | 22.53 | 160 | 5.8997 | .4822 | |||

| 0.674 | 3.152 | 27.57 | XXHY | 6.7927 | .4054 | |||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 | 4.1161 | 1.0979 | ||

| 0.219 | 5.125 | 12.51 | 4.7279 | 1.0716 | ||||

| 0.258 | 5.047 | 14.63 | STD. | 40 | 5.4500 | 1.0391 | ||

| 0.281 | 5.001 | 15.87 | 5.8644 | 1.0204 | ||||

| 0.312 | 4.939 | 17.51 | 6.4074 | .99647 | ||||

| 0.344 | 4.875 | 19.19 | 6.9358 | .9696 | ||||

| 0.375 | 4.813 | 20.80 | XHY | 80 | 7.4300 | .9449 | ||

| 0.500 | 4.563 | 27.06 | 120 | 9.2534 | .8495 | |||

| 0.625 | 4.313 | 32.99 | 160 | 10.7976 | .7590 | |||

| 0.750 | 4.063 | 38.59 | XXHY | 12.0954 | .6734 | |||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 | 5 | 3.5769 | 1.6748 | |

| 0.134 | 6.357 | 9.30 | 10 | 4.3475 | 1.6488 | |||

| 0.156 | 6.313 | 10.79 | 5.0107 | 1.6260 | ||||

| 0.188 | 6.249 | 12.94 | 5.9351 | 1.5937 | ||||

| 0.203 | 6.219 | 13.94 | 6.3804 | 1.5780 | ||||

| 0.219 | 6.187 | 15.00 | 6.8261 | 1.5620 | ||||

| 0.250 | 6.125 | 17.04 | 7.6905 | 1.5306 | ||||

| 0.280 | 6.065 | 18.99 | STD. | 40 | 8.4958 | 1.5008 | ||

| 0.312 | 6.001 | 21.06 | 9.3416 | 1.4688 | ||||

| 0.344 | 5.937 | 23.10 | 10.111 | 1.4391 | ||||

| 0.375 | 5.875 | 25.05 | 10.893 | 1.4082 | ||||

| 0.432 | 5.761 | 28.60 | XHY | 80 | 12.224 | 1.3541 | ||

| 0.500 | 5.625 | 32.74 | 13.711 | 1.2909 | ||||

| 0.562 | 5.501 | 36.43 | 120 | 14.9806 | 1.2346 | |||

| 0.625 | 5.375 | 40.09 | 16.1821 | 1.1787 | ||||

| 0.719 | 5.187 | 45.39 | 160 | 17.8243 | 1.0977 | |||

| 0.864 | 4.897 | 53.21 | XXHY | 20.025 | .9784 | |||

| 1.000 | 4.625 | 60.13 | 21.7719 | .8727 | ||||

| 1.125 | 4.375 | 66.14 | 23.1237 | .7809 |

ASTM A106 GRADE B / SA106 GR B PIPE WELDING PROCEDURE

Carbon steel is a large category of steel that encompasses many varying chemical compositions. Each type of carbon steel requires different considerations when welding. For example if you choose Low carbon steel to weld which is typically the most readily welded steel in a room temperature environment. These low carbon steel suitable for welding include C1008, C1018, A36, A1011 and A500.

Medium carbon steel such as C1045 typically requires preheat and post-heat treatment to avoid weld cracking. High carbon steel is even more prone to weld cracking than the other two groups of carbon steel. Welding high carbon steel will most likely require very thorough preheating and post-heating processes to avoid this. It could also require special welding filler metals.

Standards referenced in the production of ASTM A106 pipes include the following ASTM standards:

a. ASTM A530/A530M: This specification outlines the common requirements for carbon and alloy pipes.

b. E213: The standard governing the Ultrasonic Examination test.

c. E309: The standard for the Eddy Current examination test.

d. E381: The standard detailing the Macroetch test plan for steel products like steel bars, steel billets, blooms, and forging steels.

e. E570: The standard outlining the test plan for the flux leakage test of ferromagnetic steel pipes and pipeline products.

f. Related ASME Standard:

g. ASME B 36.10M: The standard specification for nominal sizes of welded and seamless steel pipes.

h. Related Military standard:

i. MIL-STD-129: The standard addressing the markings of shipment and storage.

j. MIL-STD-163: The standard governing the storage and shipment of steel forging products.

k. Related federal standard:

l. Fed. Std. No. 123: The standard for marking and shipments for civil agencies.

m. Fed. Std. No. 183: The standard specification for continuous ID marking for steel products.

n. Surface standard:

o. SSPC-SP 6: The standard specifying surface preparation requirements.

Heat Treatment

Heat treatment requires considering the type of pipes being produced; those made through cold-drawn processes require normalized temperatures while hot finishing methods do not necessitate any additional processes for heat treatment.

ASTM A106 GRADE B CHEMICAL COMPOSITION

| Standard | Grade | Process | Chemical Composition % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C max | Mn* | P max | S max | Si min | Cr˟ max | Cu˟ max | Ni˟ max | Mo˟ max | V˟ max | |||

| ASTM A106-15 | B | SMLS | 0.30* | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ASTM A106-15 | C | SMLS | 0.35* | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| ASTM A53-12 | B | SMLS | 0.30* | 1.20 | 0.05 | 0.045 | — | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

ASTM A106 SEAMLESS PRESSURE PIPE MECHANICAL PROPERTIES

ASTM A106 grade b yield strength

| ASTM A106 Grade A | ASTM A106 Grade B | ASTM A106 Grade C | ||

|---|---|---|---|---|

| ASTM A106 | Tensile strength, min, psi (MPa) | 48000(330) | 60000(415) | 70000(485) |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | 40000(275) | |

ASTM A106 GRADE B PIPE YIELD AND TENSILE STRENGTH

| Seamless | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

MAXIMUM ALLOWABLE HARDNESS A106

ASTM A106 grade b hardness : No hardness specific in SA-106. A106 don’t have an imposed Brinell test value but approx 110-150 usually on new pipe A106 grade B. Grade A234 WPB is made from A106 grade B and have an imposed value of 197 HB maximum

A106 PIPE VS A333 / A106 PIPE VS A53

DIFFERENCES IN CHEMICAL COMPOSITION

| Standard | Grade | Chemical Composition % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Cr | Cu | Ni | Mo | V | ||

| ASTM A106 | B | ≤0.30 | 0.29-1.06 | ≤0.035 | ≤0.035 | >0.10 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| ASTM A53 | B | ≤0.30 | ≤1.20 | ≤0.05 | ≤0.045 | – | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| API 5L | B(PSL-1) | ≤0.28 | ≤1.20 | ≤0.030 | ≤0.030 | – | – | – | – | – | – |

| DIN 1629, DIN 2448 |

St 37.0 | ≤0.17 | – | ≤0.040 | ≤0.040 | – | – | – | – | – | – |

| St 44.0 | ≤0.21 | – | ≤0.040 | ≤0.040 | – | – | – | – | – | – | |

| EN10210 | S235JRH | ≤0.17 | ≤1.40 | ≤0.040 | ≤0.040 | – | – | – | – | – | – |

| GB/T8163, GB/T8162 |

10# | 0.07-0.13 | 0.35-0.65 | ≤0.035 | ≤0.035 | 0.07-0.37 | ≤0.15 | ≤0.25 | ≤0.30 | – | – |

| 20# | 0.17-0.23 | 0.35-0.65 | ≤0.035 | ≤0.035 | 0.17-0.37 | ≤0.25 | ≤0.25 | ≤0.30 | – | – | |

DIFFERENCES IN MECHANICAL A106 STEEL PROPERTIES

| Standard | Grade | Tensile Strength (MPa) |

Yield Strength (MPa) |

Trans.Elongation (%) |

Impact Test (J) |

|---|---|---|---|---|---|

| ASTM A106 | B | >415 | ≥240 | ≥16.5 | – |

| ASTM A53 | B | >415 | ≥240 | – | – |

| API 5L | B(PSL-1) | >414 | ≥241 | As clause a | – |

| DIN 1629 | St 37.0 | 350-480 | ≥235 | ≥23 | – |

| DIN 2448 | St 44.0 | 420-550 | ≥275 | ≥19 | – |

| EN10210 | S235JRH | 360-510 | ≥235 | ≥26 | 27 (+20°C) |

| GB/T 8163 | 10# | 335-475 | ≥205 | ≥24 | – |

| GB/T 8162 | 20# | 410-550 | ≥245 | ≥20 | – |

A53 PIPE VS A106 PIPE – (4) ASTM A106 GRADE B MECHANICAL PROPERTIES

| Grade A | Grade B | Grade C | ||

|---|---|---|---|---|

| ASTM A53 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | ||

| ASTM A106 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | 70000(485) |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | 40000(275) | |

READY STOCK! SALE ON FOLLOWING SIZES, ORDER NOW

| PIPE SMLS ASTM A106 GRADE II, DIA 1/2’’ X 3.73MM, SCH 80 |

| PIPE SMLS ASTM A106 GRADE II, DIA 3/4’’ X 3.91MM, SCH 80 |

| PIPE SMLS ASTM A106 GRADE II, DIA 1’’ X 4.55MM, SCH 80 |

| PIPE SMLS ASTM A106 GRADE II, DIA 1 1/2’’ X 5.08MM, SCH 80 |

| PIPE SMLS ASTM A106 GRADE 2, DIA 2’’ X 5.54MM, SCH 80 |

| PIPE SMLS ASTM A106 GRADE II, DIA 3’’ X 5.49MM, SCH 40 |

| PIPE SMLS ASTM A106 GRADE II, DIA 4’’ X 6.02MM, SCH 40 |

| PIPE SMLS ASTM A106 GRADE II, DIA 10’’ X 9.27MM, SCH 40 |

| PIPE SMLS ASTM A106 GRADE II, DIA 12’’ X 10.31MM, SCH 40 |

| PIPE SMLS ASTM A106 GRADE II, DIA 14 SCH 40 |