When existing pipe systems need flange connections without cutting or welding, split flanges provide the ideal solution. These innovative two-piece systems revolutionize how maintenance teams and engineers approach piping modifications, offering a secure connection method that eliminates the time and cost associated with traditional welding operations.

Split flanges have become essential components across industries ranging from chemical processing to automotive exhaust repairs. Their unique design allows for easy installation on existing piping without the need for specialized welding tools or extensive system shutdowns. Whether you’re dealing with glass lined reactors, exhaust pipe modifications, or hydraulic system maintenance, understanding split flange technology can significantly improve your operational efficiency.

This comprehensive guide covers everything you need to know about split flange systems, from basic construction principles to advanced selection criteria and troubleshooting techniques.

What is a Split Flange

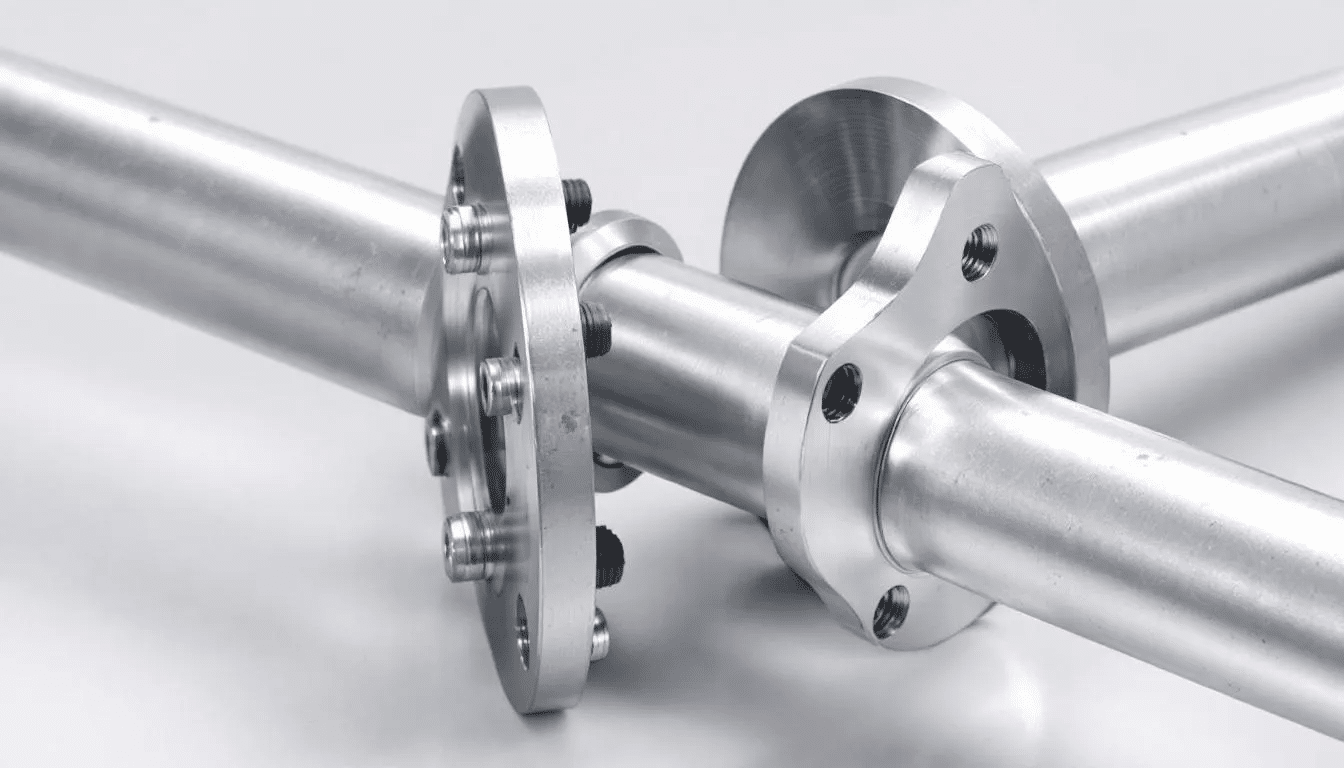

A split flange is a two-piece flange system that bolts together around pipes, eliminating the need for welding or cutting existing piping. Unlike traditional one-piece flanges that require pipe modifications for installation, split flanges consist of two interlocking halves that can be positioned around existing pipes and secured with nuts and bolts.

The basic construction involves two identical halves that feature precision-machined surfaces designed to create a tight seal when bolted together. Each half contains bolt holes that align perfectly when the pieces are assembled, allowing for consistent clamping force distribution around the entire circumference of the pipe.

The key advantage of split flanges lies in their ability to provide easy installation and removal for maintenance access. This design feature makes them particularly valuable in situations where system downtime must be minimized or where access to pipe ends is restricted. Maintenance teams can install or remove split flanges without disconnecting lengthy pipe sections or disturbing adjacent equipment.

The gasket system in split flanges typically uses compressed sealing materials that conform to the mating surfaces, creating a leak-resistant connection suitable for various pressure and temperature applications. This sealing mechanism ensures reliable performance while maintaining the ability to disassemble the connection when needed.

Types of Split Flanges

Split flange systems are available in several configurations designed to meet specific industry requirements and applications. Each type offers unique features and specifications tailored to particular operating conditions and installation requirements.

ANSI 150 Split Flanges

ANSI 150 split flanges represent a widely used standard in industrial applications, available in sizes from 1½” to 4” with maximum operating pressure of 150 PSI. These flanges are designed to meet ANSI Class 150 pressure and temperature specifications, making them suitable for a broad range of industrial processes.

The ANSI 150 specification ensures compatibility with grooved adapters and raised face flanged components commonly found in process piping systems. These flanges are typically supplied with Buna gaskets and couplers upon customer request, providing a complete connection solution.

Key specifications for ANSI 150 split flanges include:

|

Size |

Maximum Pressure | Bolt Pattern | Weight (lbs) |

|---|---|---|---|

| 1½” | 150 PSI | 4-bolt |

2.5 |

|

2” |

150 PSI | 4-bolt | 3.2 |

| 3” | 150 PSI | 4-bolt |

5.8 |

|

4” |

150 PSI | 8-bolt |

8.7 |

The threaded and blind configurations available in this series provide flexibility for different connection requirements. Threaded configurations allow for direct connection to threaded pipe systems, while blind configurations are ideal for applications requiring a flat, sealed surface.

Automotive Exhaust Split Flanges

Automotive exhaust split flanges are specifically designed for exhaust system repairs and modifications. Common sizes include 2 inch and 2.5 inch flat oval designs that accommodate standard exhaust pipes found in most vehicles.

These flanges are available in multiple materials to suit different performance and budget requirements:

- Mild steel: Cost-effective option for basic repair applications

- Stainless steel: Enhanced corrosion resistance for high-performance applications

- Galvanized steel: Balanced approach offering improved rust protection over mild steel

The 2.25 inch (57mm) size is particularly popular for European vehicle applications, fitting standard exhaust pipe diameters commonly found in this market. Installation hardware typically includes Allen bolts for secure mounting, providing reliable clamping force even under the vibration and thermal cycling conditions typical in automotive applications.

Automotive split flanges eliminate the need for welding exhaust pipes, making them ideal for quick repairs in professional shops or DIY maintenance. This capability is particularly valuable when connecting catalytic converters, mufflers, or other exhaust components without damaging heat-sensitive parts through welding operations.

Applications and Industries

Split flange systems serve critical roles across diverse industrial sectors, each leveraging the unique installation and maintenance advantages these components provide. The versatility of split flange designs makes them suitable for applications ranging from high-purity chemical processing to heavy-duty automotive repairs.

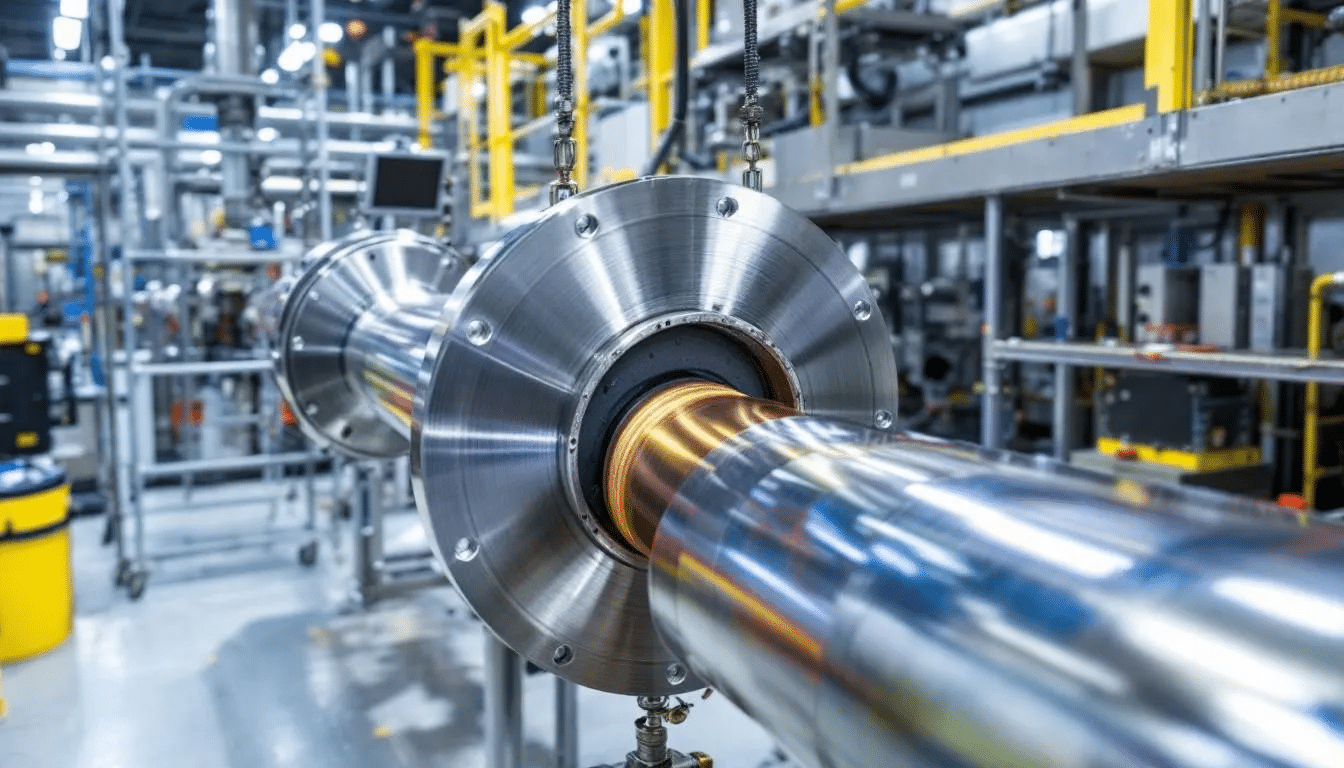

Glass lined piping systems in chemical and pharmaceutical industries represent one of the most demanding applications for split flanges. These systems require connections that maintain the integrity of the glass lining while providing reliable sealing under corrosive conditions. Split flanges allow maintenance teams to service these systems without damaging the delicate glass surfaces that traditional welding might compromise.

In automotive applications, split flanges have become the standard solution for exhaust system repairs. They provide a reliable method for connecting catalytic converters, exhaust pipes, and muffler systems without the heat damage that welding can cause to sensitive emission control components. This application is particularly important in modern vehicles where precise exhaust gas management is critical for emissions compliance.

Machine tools, steel, textile, and petrochemical industries utilize split flanges in hydraulic systems that require frequent maintenance access. These applications often involve high-pressure fluid systems with BSP, NPT, UNF, JIC, and SAE flange connections where traditional welded joints would create maintenance challenges.

The food and beverage industry also benefits from split flange technology, particularly in sanitary piping systems where easy disassembly for cleaning is essential. The ability to remove and reinstall connections without welding helps maintain the hygienic standards required in these applications while reducing cleaning time and complexity.

Materials and Specifications

Material selection for split flanges plays a crucial role in determining their performance, longevity, and suitability for specific applications. The choice of material affects not only the mechanical properties but also the corrosion resistance and cost-effectiveness of the installation.

SS 304 stainless steel represents the premium material choice for split flanges, offering excellent corrosion resistance in harsh chemical environments. This austenitic stainless steel grade provides superior resistance to a wide range of chemicals, making it ideal for pharmaceutical, food processing, and chemical manufacturing applications. The material maintains its properties across a broad temperature range and resists both uniform and localized corrosion.

Mild steel options provide cost-effective solutions with adequate durability for many industrial applications. While not offering the corrosion resistance of stainless steel, mild steel split flanges are suitable for dry environments or applications where cost considerations outweigh corrosion concerns. These flanges often receive protective coatings to enhance their service life.

Galvanized steel coatings offer enhanced rust and corrosion protection compared to uncoated mild steel. The zinc coating provides sacrificial protection, extending the service life of the flange in moderately corrosive environments. This material choice represents a balanced approach between cost and corrosion resistance.

Technical Specifications

PN 16 pressure ratings ensure compliance with European standards, making these flanges suitable for international applications. The PN 16 designation indicates a nominal pressure rating of 16 bar (approximately 232 PSI), providing adequate pressure capability for many industrial processes.

Detailed dimension tables cover pipe, flange, and bolt specifications in both mm and inches, ensuring compatibility with various international piping standards. These specifications include critical dimensions such as:

- Bolt circle diameter

- Bolt hole diameter and quantity

- Flange thickness and outer diameter

- Gasket groove dimensions (where applicable)

Weight specifications and bolt hole patterns facilitate proper installation planning and structural support requirements. Understanding these specifications helps engineers determine the appropriate support systems and installation procedures for different applications.

Flat face and raised face configurations accommodate different sealing requirements. Flat face designs provide uniform contact pressure across the entire gasket surface, while raised face configurations concentrate sealing pressure on a smaller area, often providing superior sealing performance.

Dust-inhibiting paint finishes on ductile iron bodies extend service life by protecting against environmental corrosion. These protective coatings are particularly important in outdoor installations or environments with high humidity or chemical exposure.

Installation Advantages

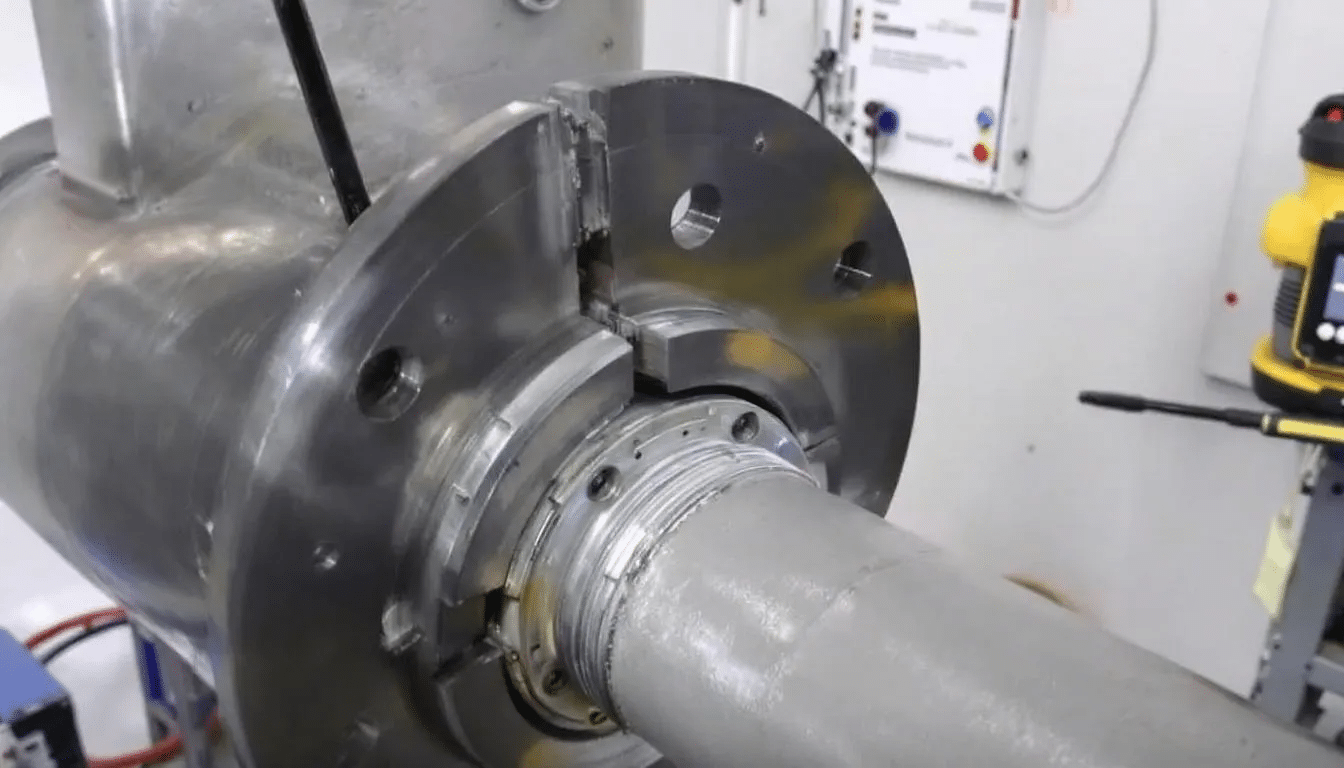

The primary advantage of split flanges lies in their ability to install on existing pipe systems without welding or cutting requirements. This capability transforms maintenance operations by eliminating the need for hot work permits, specialized welding equipment, and the associated safety protocols required for welding operations.

Reduced labor costs and installation time compared to traditional flanges create significant economic benefits. Installation teams can complete split flange installations in a fraction of the time required for welded connections, reducing both direct labor costs and system downtime. This time savings is particularly valuable in continuous process industries where production interruptions are costly.

Easy access for maintenance, inspection, and component replacement represents another key advantage. Split flanges can be removed and reinstalled multiple times without degrading their sealing performance, enabling routine maintenance that would be impossible with welded connections. This capability is essential in applications requiring regular inspection or component replacement.

Professional installation is recommended for optimal performance and safety, particularly in high-pressure or critical applications. While split flanges are designed for straightforward installation, proper torque specifications and gasket selection require technical expertise to ensure reliable operation.

The elimination of heat-affected zones that occur with welding prevents metallurgical changes in the base pipe material. This advantage is particularly important in applications involving heat-sensitive materials or where maintaining specific material properties is critical for process performance.

Selection Guide

Selecting the appropriate split flange requires careful consideration of operating conditions, system requirements, and installation constraints. The selection process should begin with a thorough evaluation of the application requirements and operating environment.

Operating pressure requirements represent the primary selection criterion. For ANSI applications, the 150 PSI rating covers many industrial processes, but higher pressure applications may require specialized designs or alternative connection methods. It’s essential to include safety factors and consider pressure spikes that may occur during system operation.

Matching pipe diameter with appropriate flange size ensures proper fit and sealing performance. The available range of 1½” to 4” covers most standard industrial piping applications, but custom sizes may be required for specialized systems. Accurate measurement of existing pipe outer diameter is crucial for proper flange selection.

Material selection should be based on corrosion resistance needs and budget considerations. The decision matrix should consider:

- Chemical compatibility with process fluids

- Temperature exposure during operation

- Environmental conditions (humidity, salt spray, etc.)

- Required service life and maintenance intervals

- Total cost of ownership including replacement cycles

Compatibility verification with existing flange standards and gasket requirements prevents installation problems and ensures reliable sealing. Different flange standards may have varying bolt patterns, gasket grooves, or sealing surface finishes that affect compatibility.

Maintenance and Troubleshooting

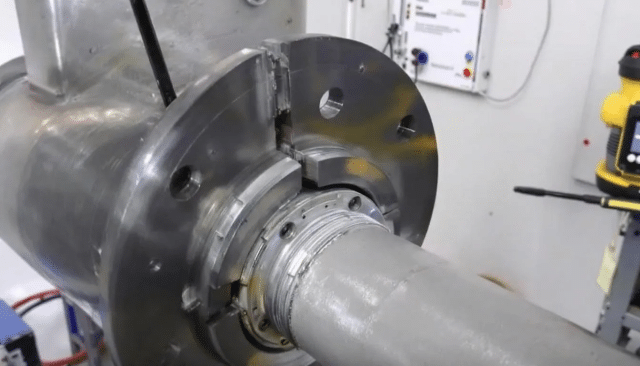

Regular inspection protocols ensure continued reliable performance of split flange connections. Inspection should focus on areas where problems typically develop, including bolt tension, gasket condition, and flange surface integrity.

Visual inspection for rust, leaks, and visible damage should be conducted during routine maintenance intervals. Pay particular attention to areas where corrosion typically initiates, such as bolt holes, gasket grooves, and areas where dissimilar materials are in contact. Early detection of corrosion allows for corrective action before failure occurs.

Proper bolt torque specifications prevent leaks and ensure secure connections throughout the service life. Under-tightening can result in gasket compression loss and subsequent leakage, while over-tightening may damage the gasket or flange faces. Use calibrated torque tools and follow manufacturer specifications for consistent results.

Gasket replacement intervals should be based on operating conditions and material compatibility. Factors affecting gasket life include:

- Temperature cycling frequency and magnitude

- Chemical exposure and compatibility

- Pressure cycling and magnitude

- Vibration levels and frequency

Common Issues and Solutions

Leak prevention requires proper gasket selection and surface preparation. The most effective approach involves matching gasket material to the specific application requirements and ensuring that flange faces are clean and undamaged before assembly.

Corrosion protection strategies become critical in harsh operating environments. Options include:

- Protective coatings on carbon steel components

- Material upgrades to stainless steel or other corrosion-resistant alloys

- Environmental controls to reduce moisture and chemical exposure

- Regular cleaning and maintenance schedules

Bolt replacement procedures address worn or damaged fasteners that can compromise connection integrity. Replacement bolts should match the original specifications for material, strength, and dimensions. In corrosive environments, consider upgrading to more corrosion-resistant bolt materials.

Signs of failure requiring immediate attention include excessive noise from the connection area, visible damage to flange components, and loose connections that cannot be corrected by proper torquing. When these conditions occur, evaluate whether repair is feasible or if complete replacement is necessary.

The decision between replacement and repair depends on the extent of damage, criticality of the application, and cost considerations. Minor surface corrosion may be addressed through cleaning and protective coating application, while significant mechanical damage typically requires component replacement.

Regular maintenance schedules tailored to the specific application and operating environment help prevent unexpected failures and extend component life. These schedules should consider the manufacturer’s recommendations, industry best practices, and site-specific operating conditions to optimize maintenance intervals and procedures.

Split flange systems continue to prove their value across industries by providing reliable, maintainable connections that eliminate the need for welding while delivering secure, leak-resistant performance. Their versatility in materials, sizes, and configurations ensures suitable solutions for virtually any piping application requiring removable flange connections.

Split Flange

Split flanges have become essential components across industries ranging from chemical processing to automotive exhaust repairs. Their unique design allows for easy installation on existing piping without the need for specialized welding tools or extensive system shutdowns. Whether you’re dealing with glass lined reactors, exhaust pipe modifications, or hydraulic system maintenance, understanding split flange technology can significantly improve your operational efficiency.

Product Brand: Sachiya Steel International Private Limited

Product Currency: INR

Product Price: 150

Price Valid Until: 2025-12-31

Product In-Stock: InStock

5