Nickel Wire Mesh Suppliers In UAE

Nickel Wire Mesh Suppliers In UAE

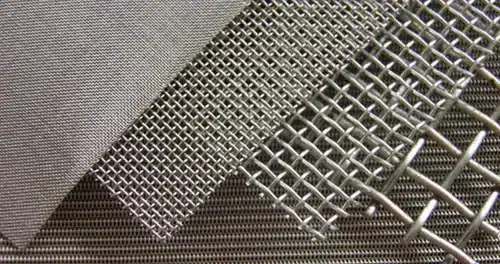

Nickel wire mesh stands out as an indispensable material in various industrial fields, from filtration systems to aerospace engineering. Finding reliable suppliers for nickel wire mesh in the UAE is paramount to the success and longevity of any project involving this component, so in this guide we delve into its intricacies as a matter of sourcing high-quality suppliers and present Sachiya Steel International as your reliable partner in this endeavor.

Understanding the Importance of Quality Nickel Wire Mesh

Nickel wire mesh is widely recognized for its corrosion resistance, high temperature tolerance and superior conductivity properties – qualities which make it a popular choice in demanding environments like chemical processing plants, oil refineries and marine applications. From filtering or reinforcement applications to filtration or separation requirements, its quality has a direct bearing on performance and lifespan of industrial systems.

Considerations When Selecting Suppliers

- Quality Assurance: By choosing suppliers who adhere to stringent quality control measures, Sachiya Steel International guarantees superior products that surpass industry standards and specifications. Sachiya Steel International prioritizes quality in every step of its production process so as to provide clients with products which exceed expectations.

- Variety of Grades and Specifications: Different applications require various grades and specifications of nickel wire mesh, so any reliable supplier should provide a wide variety of grades and specifications to meet these demands. At Sachiya Steel International, we have an impressive collection of nickel wire mesh options to meet these diverse industrial demands; you are sure to find what fits best!

- Customization Capabilities: Flexibility is key when meeting unique project requirements, and working with suppliers that offer customization services allows you to get tailor-made solutions that align perfectly with your goals. Sachiya Steel International possesses the experience needed to customize nickel wire mesh according to your exact specifications for maximum performance and efficiency.

- Reliability and Timely Delivery: Sachiya Steel International provides reliable delivery at the right time to keep projects on schedule and minimize downtime, so selecting our supplier with an impressive track record in prompt deliveries ensures smooth operations. Sachiya Steel International stands behind its promises by meeting nickel wire mesh requirements on time without delays.

Exploring the Technical Specifications and Applications of Nickel Wire Mesh

Nickel wire mesh, an adaptable and highly functional material, plays an integral part in various industrial applications due to its exceptional properties and wide array of capabilities. From filtration systems to electrical components, its robustness and dependability have earned it favor among different sectors. In this article we explore its technical specifications, properties, applications and significance within modern engineering.

Technical Specifications

- Material Composition: Nickel wire mesh typically comprises high-purity nickel ranging from 99.999% purity. This ensures optimal corrosion resistance, thermal stability and electrical conductivity characteristics suitable for demanding environments.

- Wire Diameter: Nickel wire mesh comes in various wire diameters ranging from ultrafine to coarse gauges, most frequently 0.02mm (20 microns) to 1.5mm for various filtration needs and mechanical strength demands.

- Mesh Count: Mesh count refers to the number of openings or apertures per linear inch or centimeter of wire mesh. Nickel wire mesh offers a range of mesh counts that span from 2 to 500 meshes per inch (0.79 to 196 meshes per centimeter), providing for precise filtration and sieving applications.

- Weave Types: Nickel wire mesh can be manufactured in various weave patterns, including plain weave, twill weave and Dutch weave. Each type offers different benefits in terms of uniformity, strength and filtration efficiency allowing for tailored solutions tailored specifically for particular requirements.

- Width and Length: Nickel wire mesh can be purchased in rolls or sheets with standard widths ranging from 0.5 meters to 2 meters and lengths that meet customer preferences or application needs. Custom sizes can also be requested to meet special project demands.

Properties and Characteristics

- Corrosion Resistance: Nickel wire mesh offers exceptional corrosion, oxidation and chemical attack resistance in harsh environments that include acids, alkalis and corrosive gases – making it ideally suited for chemical processing, marine applications and offshore platforms.

- Nickel Wire Mesh Provides High Temperature Stability: With a melting point of approximately 1455 degC (2651degF), nickel wire mesh remains structurally sound and mechanically robust at elevated temperatures, making it suitable for applications including high-temperature filtration, sieving and heat shielding.

- Electrical Conductivity: Nickel wire mesh has excellent electrical conductivity, making it suitable for applications requiring grounding, electromagnetic shielding and battery/fuel cell electrode materials.

- Ductility and Formability: Nickel wire mesh is highly malleable, enabling its easy forming, shaping, and fabrication into complex geometries for seamless integration with industrial components and structures.

- Low Magnetic Permeability: Nickel wire mesh features low magnetic permeability, rendering it non-magnetic or weakly magnetic and making it suitable for applications where magnetic interference must be reduced, such as electronic devices and scientific instruments. This property makes the material an asset when working in environments prone to electromagnetic fields or where interference from magnetism must be reduced, such as electronic devices and scientific instruments.

Applications

- Filtration and Separation: Nickel wire mesh has become increasingly popular for solid-liquid separation, gas filtration and particle retention applications in filtration systems for chemical processing, pharmaceuticals, food & beverage and water treatment industries. Due to its precise mesh openings and high filtration efficiency it finds applications across chemical processing, pharmaceuticals, food & beverage and water treatment industries.

- Aerospace and Automotive: Nickel wire mesh has become an indispensable material in both aerospace and automotive industries due to its excellent thermal, corrosive resistance, and durability under extreme conditions. Applications include engine components, exhaust systems and fuel filtration.

- Electronics and Electrical Engineering: Nickel wire mesh has become an essential element in electronics and electrical engineering applications such as electromagnetic interference (EMI) shielding, grounding and battery electrode materials for batteries, capacitors and sensors.

- Industrial Process Equipment: Nickel wire mesh is often utilized in industrial process equipment like heat exchangers, reactors and pressure vessels for filtration, reinforcement and structural support – helping ensure reliable performance and longevity of critical components.

- Architectural and Decorative Applications: Nickel wire mesh’s aesthetic appeal and versatility has seen it used for architectural facades, interior design elements and decorative screens, adding elegance and sophistication to residential, commercial, and public spaces alike.

Conclusion

Nickel wire mesh stands out as a versatile material with many technical specifications and applications, from corrosion resistance and temperature stability to electrical conductivity and versatility. From filtration and aerospace to electronics and architecture, nickel wire mesh has become a valuable material to engineers and designers seeking innovative engineering solutions to complex challenges. Understanding its technical nuances and capitalizing on its capabilities helps engineers and designers tackle modern engineering’s biggest hurdles with success and come up with new innovative ideas using it as their medium of choice.