Schedule 40 pipes form the backbone of many industries, providing reliable transport of fluids and gases while offering structural support. In this comprehensive guide we’ll explore all that schedule 40 pipes have to offer including their dimensions, sizes, steel composition composition thickness weight. Whether you are an industry professional or DIY enthusiast this article will give you all of the knowledge you require.

Understanding Schedule 40 Pipe Dimensions

Schedule 40 pipes adhere to stringent dimensional standards that ensure compatibility and ease of use across different applications. Key dimensions to keep an eye out for include:

Nominal Pipe Size (NPS): An NPS refers to an identification size used for identification. However, it should be noted that NPS doesn’t reflect an accurate representation of an outer diameter but instead serves primarily for identification.

Outer Diameter (OD): Depending on the NPS of a pipe, its outer diameter varies – for instance a schedule 40 pipe with an NPS of 1/2 in has an outer diameter of 0.84 inches.

Wall Thickness: Schedule 40 pipes stand out from other schedules due to their consistent wall thickness; it directly correlates with their NPS size.

Schedule 40 Pipe

Common Schedule 40 Pipe Sizes

Schedule 40 pipes come in many different sizes to meet varying needs. Below are the more frequently used sizes:

| Nominal sizes | Outside diameter | Pipe Wall thickness | Weight Chart | |||

|---|---|---|---|---|---|---|

| inches | OD in inches | OD in mm | inches | mm | lb/ft | kg/m |

| 1/8 | 0.405 | 10.3 | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4 | 0.540 | 13.7 | 0.088 | 2.24 | 0.42 | 0.84 |

| 1/2 | 0.840 | 21.3 | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4 | 1.050 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1 | 1.315 | 33.4 | 0.133 | 3.38 | 1.68 | 2.50 |

| 1 1/4 | 1.660 | 42.2 | 0.140 | 3.56 | 2.27 | 3.39 |

| 1 1/2 | 1.900 | 48.3 | 0.145 | 3.68 | 2.72 | 4.05 |

| 2 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2 | 2.875 | 73.0 | 0.203 | 5.16 | 5.79 | 8.63 |

| 3 | 3.500 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2 | 4.000 | 101.6 | 0.226 | 5.74 | 9.11 | 13.57 |

| 4 | 4.500 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 5 | 5.563 | 141.3 | 0.258 | 6.55 | 14.62 | 21.77 |

| 6 | 6.625 | 168.3 | 0.280 | 7.11 | 18.97 | 28.26 |

| 8 | 8.625 | 219.1 | 0.322 | 8.18 | 28.55 | 42.55 |

| 10 | 10.750 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 12 | 12.750 | 323.8 | 0.406 | 10.31 | 53.52 | 79.73 |

| 14 | 14 | 355.6 | 0.375 | 11.13 | 54.57 | 94.55 |

| 16 | 16 | 406.4 | 0.500 | 12.70 | 82.77 | 123.30 |

| 18 | 18 | 457.0 | 0.562 | 14.27 | 104.67 | 155.80 |

| 20 | 20 | 508.0 | 0.594 | 15.09 | 123.11 | 183.42 |

| 24 | 24 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 32 | 32 | 813.0 | 0.688 | 17.48 | 230.08 | 342.91 |

Referring to the conversion table is all that’s necessary in establishing relationships among pipe sizes, schedules and wall thicknesses.

| Metric diameter | Inch | Out diameter | Out diameter point to the thickness | ||

| A | B | ASME | STD | SCH40 | SCH80 |

| 8 | 1/4′ | – | – | – | – |

| 10 | 3/8 | – | – | – | – |

| 15 | 1/2″ | 21.3 | 2.77 | 2.77 | 3.73 |

| 20 | 3/4″ | 26.7 | 2.87 | 2.87 | 3.91 |

| 25 | 1″ | 33.4 | 3.38 | 3.38 | 4.55 |

| 32 | 1.1/4″ | 42.2 | 3.56 | 3.56 | 4.85 |

| 40 | 1.1/2″ | 48.3 | 3.68 | 3.68 | 5.08 |

| 50 | 2″ | 60.3 | 3.91 | 3.91 | 5.54 |

| 65 | 2.1/2″ | 73 | 5.16 | 5.16 | 7.01 |

| 80 | 3″ | 88.9 | 5.49 | 5.49 | 7.62 |

| 90 | 3.1/2″ | 101.6 | 5.74 | 5.74 | 8.08 |

| 100 | 4″ | 114.3 | 6.02 | 6.02 | 8.56 |

| 125 | 5″ | 141.3 | 6.55 | 6.55 | 9.53 |

| 150 | 6″ | 168.3 | 7.11 | 7.11 | 10.97 |

| 200 | 8″ | 219.1 | 8.18 | 8.18 | 12.7 |

| 250 | 10″ | 273 | 9.27 | 9.27 | 15.09 |

| 300 | 12″ | 323.8 | 9.53 | 10.31 | 17.48 |

| 350 | 14″ | 355.5 | 9.53 | 11.13 | 19.05 |

| 400 | 16″ | 406.4 | 9.53 | 12.7 | 21.44 |

| 450 | 18″ | 457.2 | 9.53 | 14.27 | 23.83 |

| 500 | 20″ | 508 | 9.53 | 15.09 | 26.19 |

| 550 | 22″ | 558.8 | 9.53 | – | 28.58 |

| 600 | 24″ | 609.6 | 9.53 | 17.48 | 30.96 |

| 650 | 26″ | 660.4 | 9.53 | – | – |

| 700 | 28″ | 711.2 | 9.53 | – | – |

| 750 | 30″ | 762 | 9.53 | – | – |

| 800 | 32″ | 812.8 | 9.53 | 17.48 | – |

| 850 | 34″ | 863.5 | 9.53 | 17.48 | – |

| 900 | 36″ | 914.4 | 9.53 | 19.05 | – |

| 950 | 38″ | 965.2 | 9.53 | – | – |

| 1000 | 40″ | 1016 | 9.53 | – | – |

| 1050 | 42″ | 1066.8 | 9.53 | – | – |

| 1100 | 44″ | 1117.6 | 9.53 | – | – |

| 1150 | 46″ | 1168.4 | 9.53 | – | – |

| 1200 | 48″ | 1219.2 | 9.53 | – | – |

Schedule 40 Pipe is made of steel material

Schedule 40 Pipe Steel Composition:

Steel is typically chosen for schedule 40 pipes due to its multiple advantages; specifically low carbon steel provides several. These advantages include:

Strength: Steel is widely revered for its strength, making it suitable for use both structurally and fluid-carrying applications.

Durability: Low carbon steel provides exceptional corrosion resistance, prolonging the lifespan of schedule 40 pipes even in harsh environments.

Steel pipes can be utilized in numerous applications, from plumbing and HVAC systems to industrial processes.

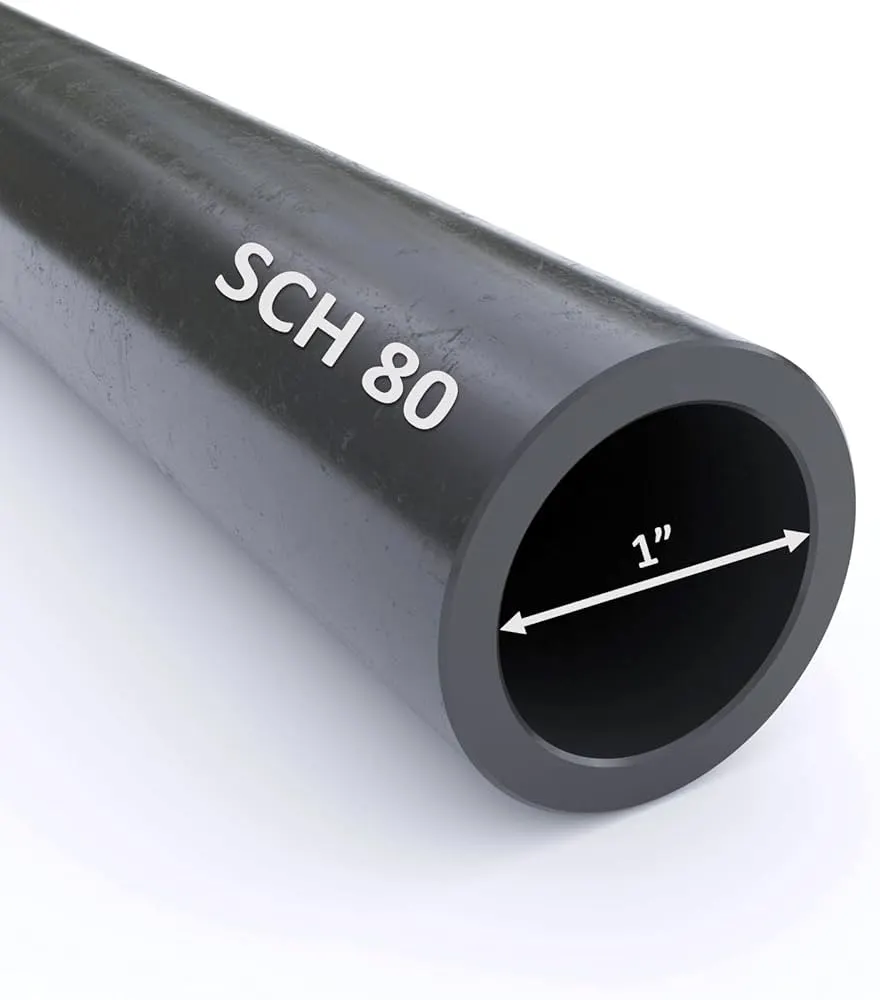

Schedule 40 Pipe Thickness

How Thick Is Schedule 40 Pipe?

Schedule 40 pipes come with different thicknesses depending on their function and load-bearing capacities, with wall thickness being identified by schedules according to NPS ratings (National Pipe Size Standards). As an example:

An NPS 1-inch schedule 40 pipe typically features a wall thickness of approximately 0.133 inches, with thicker walls to withstand higher pressures in larger NPS sizes. When selecting schedule 40 pipes for specific applications, understanding wall thickness is vitally important.

Schedule 40 Pipe Dimensions and Wall Thickness

| Pipe Sizes* |

O.D.

(in.) |

Schedule (40) Pipe

Wall Thickness (in.)** |

|

|---|---|---|---|

| Sch.40 | |||

| Wall (in) | I.D. (in) | ||

| 1/8″ | 0.41 od | 0.07 in | 0.269 id |

| Weight (lbs/ft.) |

Steel | 0.247 lbs/ft | |

| Stainless | |||

| Aluminum | |||

| 1/4″ | 0.54 od | 0.090 in | 0.364 id |

| Weight (lbs/ft.) |

Steel | 0.429 lbs/ft | |

| Stainless | |||

| Aluminum | 0.147 lbs/ft | ||

| 3/8″ | 0.675 od | 0.091 in | 0.493 id |

| Weight (lbs/ft.) |

Steel | 0.570 lbs/ft | |

| Stainless | |||

| Aluminum | 0.196 lbs/ft | ||

| 1/2″ | 0.840 od | 0.109 in | 0.622 id |

| Weight (lbs/ft.) |

Steel | 0.850 lbs/ft | |

| Stainless | |||

| Aluminum | 0.294 lbs/ft | ||

| 3/4″ | 1.050 od | 0.113 in | 0.824 id |

| Weight (lbs/ft.) |

Steel | 1.13 lbs/ft | |

| Stainless | |||

| Aluminum | 0.391 | ||

| 1″ | 1.315 od | 0.133 in | 1.049 id |

| Weight (lbs/ft.) |

Steel | 1.68 lbs/ft | |

| Stainless | |||

| Aluminum | 0.581 lbs/ft | ||

| 1-1/4″ | 1.66 od | 0.140 in | 1.380 id |

| Weight (lbs/ft.) |

Steel | 2.27 lbs/ft | |

| Stainless | |||

| Aluminum | 0.785 lbs/ft | ||

| 1-1/2″ | 1.90 od | 0.145 in | 1.610 id |

| Weight (lbs/ft.) |

Steel | 2.72 lbs/ft | |

| Stainless | |||

| Aluminum | 0.939 lbs/ft | ||

| 2″ | 2.375 od | 0.154 in | 2.067 id |

| Weight (lbs/ft.) |

Steel | 3.66 lbs/ft | |

| Stainless | |||

| Aluminum | 1.260 lbs/ft | ||

| 2-1/2″ | 2.875 od | 0.203 in | 2.469 id |

| Weight (lbs/ft.) |

Steel | 5.80 lbs/ft | |

| Stainless | |||

| Aluminum | 2.000 lbs/ft | ||

| 3″ | 3.50 od | 0.216 in | 3.068 id |

| Weight (lbs/ft.) |

Steel | 7.58 lbs/ft | |

| Stainless | |||

| Aluminum | 2.620 lbs/ft | ||

| 3-1/2″ | 4.00 od | 0.226 in | 3.550 id |

| Weight (lbs/ft.) |

Steel | 9.12 lbs/ft | |

| Stainless | |||

| Aluminum | 3.150 lbs/ft | ||

| 4″ | 4.50 od | 0.237 in | 4.026 id |

| Weight (lbs/ft.) |

Steel | 10.80 lbs/ft | |

| Stainless | |||

| Aluminum | 3.730 lbs/ft | ||

| 5″ | 5.563 od | 0.258 in | 5.047 id |

| Weight (lbs/ft.) |

Steel | 14.63 lbs/ft | |

| Stainless | |||

| Aluminum | 5.050 lbs/ft | ||

| 6″ | 6.625 od | 0.280 in | 6.065 id |

| Weight (lbs/ft.) |

Steel | 18.99 lbs/ft | |

| Stainless | |||

| Aluminum | 6.560 lbs/ft | ||

| 8″ | 8.625 od | 0.322 in | 7.981 id |

| Weight (lbs/ft.) |

Steel | 28.58 lbs/ft | |

| Stainless | |||

| Aluminum | 9.88 lbs/ft | ||

| *Nominal sizes apply – Pipe Size is the generic Industry Size Standard for reference only **Tolerances may vary slightly from each manufacturer |

|||

Calculating the Weight of Schedule 40 Steel Pipe

Calculating the Weight of Schedule 40 Steel Pipe: In order to estimate the weight of a schedule 40 steel pipe, use this formula:

Weight (lbs)

=

Nominal Pipe Size (NPS)

×

Wall Thickness (inches)

×

10.68

Weight (lbs)=Nominal Pipe Size (NPS)×Wall Thickness (inches)×10.68

Keep in mind that this calculator only gives an approximate weight, as actual weights may differ slightly due to manufacturing tolerances.

Applications of Schedule 40 Pipe

Versatile Applications: Its Schedule 40 pipes have become an indispensable tool across multiple fields due to their durability and dependability, including applications that include:

- Plumbing: Schedule 40 pipes are widely utilized for water distribution in both residential and commercial settings due to their corrosion-resistant qualities.

- HVAC Systems: HVAC pipes are ideal for heating, ventilation and air conditioning systems due to their superior durability and temperature resistance.

- Industrial Processes: Schedule 40 pipes play an essential role in industrial settings for transporting various liquids and gases – such as chemicals or compressed air – across their paths.

- Structural Support: Handrails, fencing and scaffolding all utilize these metal supports as integral parts of their structures.

- Agriculture: These pipes are widely utilized in agriculture for use with irrigation systems, as they can withstand pressure to efficiently distribute water across large areas.

- Oil and Gas Industry: Schedule 40 pipes are widely utilized within the oil and gas sector to transport various substances ranging from crude oil to natural gas.

Pressure Ratings for Schedule 40 Pipe

Understanding Pressure Ratings of Schedule 40 Pipes:

Understanding the pressure ratings of schedule 40 pipes is vital to making sure they will fit your intended application. Pressure ratings depend on various factors including pipe size, material and temperature; typically schedule 40 pipes have an ideal maximum pressure rating between 150 to 300 PSI which makes them suitable for most standard applications.

| Maximum Allowable Pressure (psi) (kPa) | ||

|---|---|---|

| NPS | Outside Diameter (OD) | Schedule |

| (in) | (in) (mm) |

40 |

| 1/4 | 0.54 13.7 |

7985 55057 |

| 3/8 | 0.675 17.1 |

6606 45548 |

| 1/2 | 0.84 21.3 |

6358 43838 |

| 3/4 | 1.05 26.7 |

5273 36357 |

| 1 | 1.315 33.4 |

4956 34172 |

| 1 1/4 | 1.66 42.2 |

4133 28497 |

| 1 1/2 | 1.9 48.3 |

3739 25780 |

| 2 | 2.375 60.3 |

3177 21905 |

| 2 1/2 | 2.875 73 |

3460 23857 |

| 3 | 3.5 88.9 |

3024 20850 |

| 3 1/2 | 4 102 |

2769 19092 |

| 4 | 4.5 114 |

2581 17796 |

| 5 | 5.563 141 |

2273 15672 |

| 6 | 6.625 168 |

2071 14280 |

| 8 | 8.625 219 |

1829 12611 |

| 10 | 10.75 273 |

1664 11473 |

| 12 | 12.75 324 |

1560 10756 |

| 14 | 14 356 |

1533 10570 |

| 16 | 16 406 |

1531 10556 |

| 18 | 18 457 |

1530 10549 |

| 20 | 20 508 |

1455 10032 |

| 22 | 22 559 |

|

| 24 | 24 610 |

1405 9687 |

| 30 | 30 762 |

|

| 32 | 32 813 |

1054 7267 |

| 34 | 34 864 |

992 6840 |

| 36 | 36 914 |

1021 7040 |

| 42 | 42 1067 |

875 6033 |

Prices of Schedule 40 Pipe

Cost Factors: Longer pipes like schedule 40 can vary in cost depending on several different criteria; including but not limited to their diameter, weight and diameter ranges.

Materials: Steel is the go-to material for schedule 40 pipes, though its quality and coatings may have an effect on their price.

Size: Larger pipes tend to cost more due to higher material and manufacturing expenses.

Quantity: Purchasing large amounts can often result in cost savings.

Location: Prices may differ based on your geographic location and proximity to suppliers.

Schedule 40 Steel Pipe Price in India

| 12″ Schedule 40 Steel Pipe (1ft) Length | US $9.50 |

| 24″ Schedule 40 Steel Pipe (2ft) Length | US $12.90 |

| 36″ Schedule 40 Steel Pipe (3ft) Length | US $23.40 |

| 48″ Schedule 40 Steel Pipe (4ft) Length | US $29.80 |

| 60″ Schedule 40 Steel Pipe (5ft) Length | US $38.00 |

| 72″ Schedule 40 Steel Pipe (6ft) Length | US $45.10 |

| 84″ Schedule 40 Steel Pipe (7ft) Length | US $52.00 |

| 96″ Schedule 40 Steel Pipe (8ft) Length | US $60.10 |

Please be aware that these prices are approximate and could have changed since then, for best results check with local suppliers or online retailers for updated pricing information.

Why choose Sachiya Steel International?

1. Quality Assurance: At our core is an uncompromising dedication to quality. That is why we only source schedule 40 pipes from trusted manufacturers who implement rigorous quality control procedures, guaranteeing our customers receive products which meet or surpass industry standards.

2. Comprehensive Inventory: We maintain a vast inventory of schedule 40 pipes to meet the immediate needs of our clients., from small projects to industrial applications – so whatever your need, from industrial to small scale we have you covered!

3. Global Reach: Sachiya Steel International has an international reach and our products can be found all around the world. Our efficient logistics and supply chain management ensure our products reach you promptly regardless of where they’re being shipped from.

4. Competitive Pricing: At our firm, Sachiya Steel International recognize the significance of cost-effectiveness in today’s highly competitive market. Our prices are extremely cost-effective so businesses can stay within budget without compromising on quality.

5. Customer-Centric Approach: At our core, we value long-term client relationships and place great importance on offering exceptional service to every one. Our customer support team is readily available to respond to inquiries and offer technical support, to make the buying experience a smooth one.