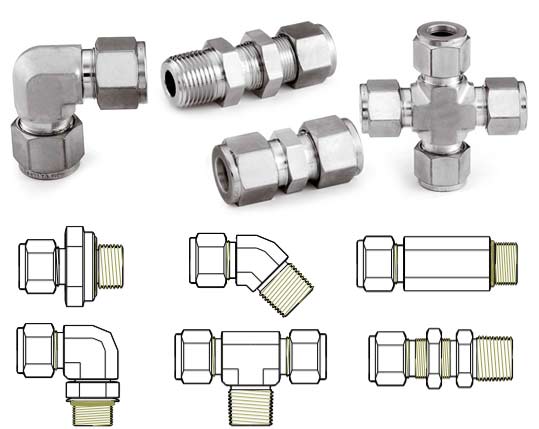

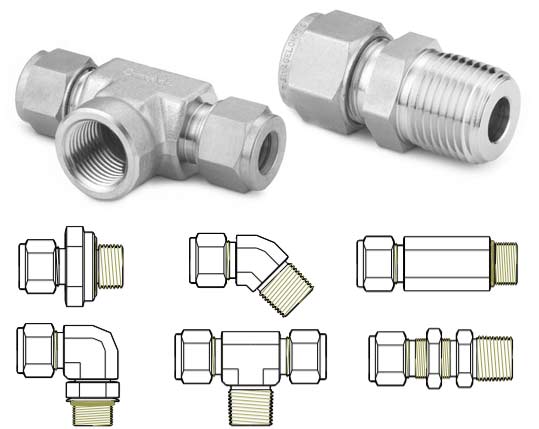

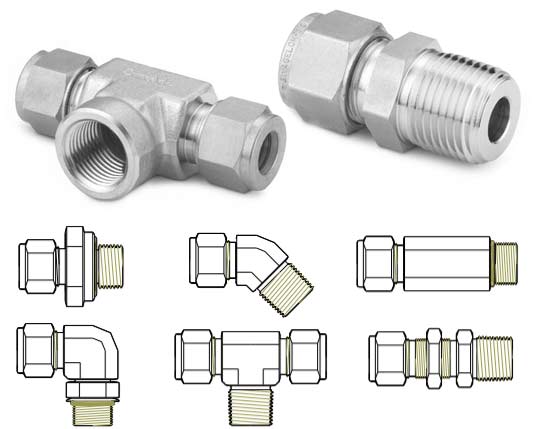

Stainless Steel 347 Tube to Male Fittings Manufacturers In India

Sachiya Steel International is one of the Leading Manufacturer And Exporter Of High Quality Stainless Steel 347 Tube to Male Fittings, which are very tough and, therefore, readily machined and formed. These Stainless Steel 347 Tube Fittings should be aged at 900 Degree F to 950 Degree F (480 Degree C to 510 Degree C) for three to six hours, where very large cross sections should be aged for longer periods. Stainless Steel 347 Compression Fittings achieve full properties through martensitic precipitation aging – a relatively simple, low temperature heat treatment.

This Stainless Steel 347 Compression Tube Fittings are processed essentially the same as the titanium – bearing 18 % nickel steels. Detailed procedures for machining, cold working, warm working, hot working, welding, nitriding, plating, forging, rolling, solution annealing, as well as recommendations for die casting applications, can be found in Stainless Steel 347 Male Connector Fittings. An additional benefit of these Stainless Steel 347 Ferrule Tube Fittings is the age hardening reaction of these nickel steels. In the solution annealed condition, Stainless Steel 347 Double Ferrule Tube Fittings are very tough, relatively soft, and therefore, readily machined and formed.

After machining or forming these 347 Stainless Steel Male Connector Fittings, a precipitation hardening (aging) process, which requires no protective atmosphere and relatively low furnace temperatures, raises the hardness to a level sufficient for many tooling applications. 347 Stainless Steel Tube Fittings are furnished in the solution annealed condition.

Stainless Steel 347 Tube to Male Fittings Specifications |

||

| Specifications | : | ASTM A276 ASME SA 479 |

| Tube Size | : | 6mm to 38mm to 1/4″ to 1 1/2″ |

| Thread |

: | NPT, BSP, BSPT, UNF, ISO, SAE etc. |

| Brass | : | ASTM B16 ASTM B 453 |

| Pressure Rating | : | 6000PSI for Stainless Steel, 300/1000/3000PSI for Brass |

SS 347 Tube To Male Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 20.00 | 10xC – 1.10 | 9.00 – 13.00 | 62.74 min |

Stainless Steel 347 Tube To Male Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Equivalent Grades for 347 Stainless Steel Ferrule Fitting Tube To Male Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

SS 347 Tube To Male Fittings Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Stainless Steel 347 Tube To Male Fittings Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and Macro Test

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)