ISMB Weight Chart And ISMC Weight Chart.

Universal Beams, Columns and C Channel Weight as per Indian Standard including ISMC/ ISMB/ ISJB/ ISLB/ ISWB

MS Channels or commonly known as C Channel, because of their C like shape is represented by its Web height & Flange width of the channel. ISMB Weight Chart And ISMC Weight Chart. MS Channel primarily carries horizontal gravitational forces and is used for bus body, EOT cranes and many more engineering industry needs. suppliers as top supplier for building material, stock all sizes/ weights of channel from companies like SAIL, RINL and other prestigious manufacturers of mild steel channel.

ISMC stands for Indian Standard Medium Weight Channel, while ISMB refers to “Indian Standard Medium Weight Beams.” The standard form ISMB is defined by specific dimensions and weight specifications as per IS codes, ensuring uniformity and reliability in structural design and standardization. The Indian Standard Medium Beam, or ISMB, is widely used in construction projects for its load-bearing capabilities, with specifications and applications standardized according to Indian Standards. The ISMB beam is particularly important for its weight calculation formulas, standard dimensions, and its critical role in construction and engineering projects, where proper selection ensures structural safety and efficiency. Both designations help categorize steel sections according to their load-bearing capacities and dimensions; ISMC full form specifically to medium-weight channels while ISMB full form to medium-weight beams; engineers and architects need to be familiar with these distinctions when selecting structural components for various construction projects.

The ISMC Weight Chart is an invaluable tool for professionals in the construction industry. Here’s why it’s essential:

- Structural Drawing: The ISMC C channel weight chart aids structural designers in selecting the appropriate ISMC channel based on the desired load-bearing capacity and the dimensions of the structure. This ensures both safety and durability for any project.

- Material Measure or Size: The weight information provided in the chart allows for precise calculation of the total material weight of a structure. This precision is crucial for purposes such as transportation, handling, and cost estimation.

- Standardization: Adhering to Indian Standard specifications, the chart ensures homogeneity and standardization within the construction industry. It offers a reliable reference for selecting the right channel based on the specific demands of a project.

- Adaptability: Engineers can easily identify suitable ISMC channels for connecting different structural elements. This feature guarantees that channels can be joined effortlessly and accurately, enhancing the overall efficiency and integrity of the construction process.

Understanding the distinctions between ISMC and ISMB is just the beginning. Utilizing tools like the ISMC Weight Chart allows construction professionals to make informed decisions, ensuring the structural integrity and cost-effectiveness of their projects.

When it comes to top manufacturers of ISMC channels in India, several names stand out for their quality and reliability. Notable companies in this industry include:

- Steel Authority of India Limited (SAIL)

- Jindal Steel and Power Limited (JSPL)

- Visakhapatnam Steel Plant (VSP)

- ESSAR

These manufacturers are renowned for their robust production capabilities and high-standard steel products, making them leaders in the market.

Shape and Description of an ISMC Channel

ISMC channels are a type of structural steel profile identified by their distinctive “C” shape. These channels are produced using a hot-rolled process, adhering to the specifications outlined in the IS 808 standard.

Here are some key features of ISMC channels:

- Shape: The channels have a unique “C” shape, providing excellent structural support.

- Dimensions: They come in various sizes, defined by their width (measured across the flanges), depth (height of the web), and length.

- Weight: Each size has a corresponding weight, ensuring it delivers the necessary strength for construction projects.

Due to their robust design, ISMC channels are widely used in construction to provide superior stability and support, preventing structural failures. The heavy-duty nature of these channels makes them ideal for various applications, ensuring that buildings and frameworks remain secure and durable.

Full form of Angle/ Channel/ Beam sections Indian Standards

- ISMB: Indian Standard Medium Weight Beam

- ISMC – Indian Standard Medium Weight Channel

- ISJB: Indian Standard Junior Beams

- ISLB: Indian Standard Light Weight Beams

- ISWB: Indian Standard Wide Flange Beams

The popular trade name in Australia the Universal Beams (UB) and Columns (UC).

| MILD STEEL CHANNELS |

| DIMENSION & PROPERTIES AS PER ISI SPECFICATION IS:2062-2006 |

| Designation |

Depth of Section

|

Width of Flange |

Thickness of Web |

Weight/Mtr |

Sectional Area |

Moduli of Section |

|

h

|

b |

t |

w |

a |

Zxx |

Zyy

|

|

(mm) |

(mm) |

(mm) |

(kg) |

(cm2) |

(cm2) |

(cm2)

|

|

ISMC 75 weight

|

75 |

40 |

4.8 |

7.1 |

9.1 |

20.3 |

4.7 |

| ISMC 100 weight |

100 |

50 |

5 |

9.6 |

12.2 |

37.3 |

7.5

|

|

ISMC 125 weight

|

125 |

65 |

5.3 |

13.1 |

16.7 |

68 |

13.4 |

| ISMC 150 weight |

150 |

75 |

5.7 |

16.8 |

21.3 |

105 |

19.4

|

|

ISMC 175 weight

|

175 |

75 |

6 |

19.6 |

24.4 |

139.8 |

22.8 |

| ISMC 200 weight |

200 |

75 |

6.2 |

22.3 |

28.5 |

181 |

26.4

|

|

ISMC 250 weight

|

250 |

82 |

7.2 |

34.2 |

39 |

307 |

38.4 |

| ISMC 300 weight |

300 |

90 |

7.8 |

36.3 |

46.3 |

428 |

47.1

|

|

ISMC 400 weight

|

400 |

100 |

8.8 |

50.1 |

63.8 |

760 |

67

|

Ms Channel Weight in Kg

|

Indian Standard

|

Sizes |

Weight in Kg Per Foot |

Weight in Kg per Meter |

| ISMC/ ISMB/ ISA |

75 * 40 * 4.8 |

2.176 |

7.14

|

|

ISMC/ ISMB/ ISA

|

100 * 50 * 5 |

2.914 |

9.56 |

| ISMC/ ISMB/ ISA |

125 * 65 * 5.3 |

3.993 |

13.10

|

|

ISMC/ ISMB/ ISA

|

150 * 75 * 5.7 |

5.121 |

16.80 |

| ISMC/ ISMB/ ISA |

175 * 75 * 6 |

5.975 |

19.60

|

|

ISMC/ ISMB/ ISA

|

200 * 75 * 6.2 |

6.798 |

22.30 |

| ISMC/ ISMB/ ISA |

250 * 82 * 9 |

10.426 |

34.2

|

|

ISMC/ ISMB/ ISA

|

300 * 90 * 7.8 |

11.067 |

36.3 |

| ISMC/ ISMB/ ISA |

400 * 100 * 8.8 |

15.274 |

50.1

|

All weights are approximate. ( ISMB Weight Chart And ISMC Weight Chart. )

JINDAL Channel Weight Chart

|

Sr. No.

|

Depth (mm) x Flange (mm) x Sectional Weight (kg/m)

|

|

1

|

ISMC 250 X 80 X 30.6 |

| 2 |

ISMC 250 X 82 X 34.2

|

|

3

|

ISMC 250 X 83 X 38.1 |

| 4 |

ISMC 250 X 83 X 38.1

|

|

5

|

ISMC 300 X 90 X 36.3 |

| 6 |

ISMC 300 X 92 X 41.5

|

|

7

|

ISMC 300 X 93 X 46.2 |

| 8 |

ISMC 400 X 100 X 50.1

|

Structural Sizes & Section weight of Beams/ Joists, Channels and Angles

|

Section

|

Dimensions |

Sectional Weight |

Length |

|

mm |

kg/m |

m

|

|

Channels

|

Bhilai Steel Plant

|

|

75 x 40 x 4.8

|

7.14 |

10 to 12

|

| 100 x 50 x 5 |

9.56 |

|

|

Durgapur Steel Plant

|

| 125 x 65 x 5.3 |

13.1 |

10 to 11.5

|

|

125 x 66 x 6

|

13.7 |

for all dimensions

|

|

150 x 75 x 5.7

|

16.8 |

|

| 150 x 76 x 6.5 |

17.7

|

|

|

175 x 75 x 6

|

19.6 |

|

| 200 x 75 x 6.2 |

22.3

|

|

|

200 x 76 x 7.5

|

24.3 |

|

|

Bhilai Steel Plant

|

|

250 x 82 x 9

|

34.2 |

10 to 12 |

|

300 x 90 x 7.8

|

36.3 |

for all dimensions

|

|

400 x 100 x 8.8

|

50.1

|

|

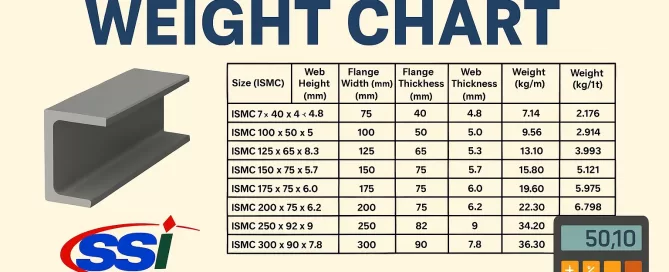

Weight Chart for ISMC Mild Steel Channels

Understanding the weight of ISMC (Indian Standard Medium Channel) Mild Steel Channels is crucial for ensuring precise engineering calculations and efficient project planning. Below is an organized weight chart detailing the dimensions and corresponding sectional weights, primarily sourced from prominent manufacturers like SAIL/JSPL and VSP.

Bhilai Steel Plant

- Dimensions: 70 x 40 x 4.8 mm

- Sectional Weight: 7.14 kg/m

- Length: 12 m and above

- Dimensions: 100 x 50 x 5 mm

- Sectional Weight: 9.56 kg/m

- Length: 12 m and above

Durgapur Steel Plant

- Dimensions: 150 x 75 x 5.7 mm

- Sectional Weight: 16.8 kg/m

- Length: Standard length 11 m and above

- Dimensions: 150 x 76 x 6.5 mm

- Sectional Weight: 17.7 kg/m

- Length: Standard length 11 m and above

- Dimensions: 200 x 75 x 6.5 mm

- Sectional Weight: 22.3 kg/m

- Length: Standard length 11 m and above

- Dimensions: 200 x 76 x 7.5 mm

- Sectional Weight: 24.3 kg/m

- Length: Standard length 11 m and above

Reagain Bhilai Steel Plant

- Dimensions: 250 x 82 x 9 mm

- Sectional Weight: 34.2 kg/m

- Length: 12 – 13.5 m

- Dimensions: 300 x 90 x 7.8 mm

- Sectional Weight: 36.3 kg/m

- Length: 12 – 13.5 m

- Dimensions: 400 x 100 x 8.8 mm

- Sectional Weight: 50.1 kg/m

- Length: 12 – 13.5 m

This weight chart provides an essential reference for selecting the appropriate ISMC channels for your structural needs. Always ensure to verify the dimensions and weights as per your specific project requirements.

Steel Channel Weight Per Kg

|

Side(mm) * Side(mm) * Thickness range (mm)

|

Section Weight (Kg/m) |

| MC *40 * 32 * 5 |

4.82

|

|

MC 75 * 40 * 4.8

|

7.14 |

| MC 100 * 50 * 5 |

9.56

|

|

MC 125 * 65 * 5.3

|

13.1 |

| MC 150 * 75 * 5.7 |

16.8

|

Manufacturing Grades:

| Steel Channel |

IS :808 – 1989 / IS :3954 – 1981 |

| Tolerance as per:- |

|

| Steel Channel |

IS :1852 – 1985 / IS :3954 – 1981 |

| Grades as per:- |

|

| Steel Channel |

IS :2062 :E250 A – 2006 |

What are the Tolerances for ISMC Channels?

When working with ISMC channels, it’s important to understand the manufacturing tolerances. These tolerances ensure that the channels meet specific dimensions and standards, which is crucial for structural integrity and performance.

Here are the key tolerances for ISMC channels:

- Web Depth Tolerance: The allowable variation for the depth of the web is ±2.5 mm. This ensures that the structural depth remains consistent for load-bearing applications.

- Flange Width Tolerance: The flange width can vary by ±2 mm. Maintaining this tolerance is essential for the proper fitting and alignment of the channels in construction projects.

- Weight per Meter Tolerance: The weight of the ISMC channel per meter can fluctuate by ±2.5%. This tolerance helps in maintaining uniformity in weight-related specifications, which is critical for calculating load and support requirements.

These tolerances are designed to maintain quality and precision in the production of ISMC channels, ensuring that they meet industry standards and perform reliably in various applications.

Mechanical Properties and Testing Requirements for ISMC Channels

Mechanical Properties

ISMC (Indian Standard Medium Channel) Channels are essential in various structural and engineering applications, and their mechanical properties are crucial to ensuring safety and performance. Here are the key mechanical properties specified under IS 808:1989:

- Tensile Strength: ISMC channels typically possess high tensile strength to bear heavy loads and withstand pulling forces.

- Yield Strength: The yield strength defines the stress at which a material begins to deform plastically. This is crucial for ensuring the channel maintains its structural integrity under load.

- Elongation: This measures the channel’s ability to stretch before breaking. Higher elongation indicates better ductility and resilience.

Testing Requirements

Ensuring the mechanical properties meet industry standards involves rigorous testing. The following are the essential testing requirements for ISMC Channels per IS 808:1989:

- Dimensional Verification: Precise measurements of length, width, and thickness are taken to ensure they meet specified dimensional standards.

- Weight Assessment: Each channel is weighed to ensure compliance with weight specifications, which is vital for maintaining consistency in load-bearing capabilities.

- Tolerance Checks: Tolerances in various dimensions are checked to confirm they fall within acceptable limits, ensuring uniformity and reliability in application.

- Mechanical Testing: This includes tensile tests to ascertain strength and elongation characteristics, confirming they meet the IS 808:1989 standards.

- Quality Control: Comprehensive quality control measures are in place, involving both destructive and non-destructive testing methods, to verify the material’s consistency and durability.

By adhering to these mechanical properties and testing requirements, ISMC Channels ensure structural reliability and safety in diverse engineering applications.

What Are the Different Grades of ISMC MS Channels?

ISMC MS (Indian Standard Medium Weight) channels are available in a variety of grades to suit different construction and manufacturing needs. Here’s a detailed look at the commonly available grades:

1. ISMC MS E350BR Channels

- High strength

- Ideal for heavy-duty applications

- Suitable for structural purposes

2. ISMC MS E350A Channels

- Medium-high strength

- Versatile use in general construction

- Cost-effective option

3. ISMC MS E410A Channel

- Higher strength compared to E350A

- Suitable for demanding structural applications

- Enhanced durability

4. ISMC MS E410BR Channel

- Another high-strength variant

- Superior performance under high load conditions

- Frequently used in industrial frameworks

5. ISMC Mild Steel E450A Channel

- Very high strength

- Best for extremely demanding environments

- Long-lasting and reliable

6. ISMC MS E450BR Channels

- Highest strength in the E series

- Ideal for maximum load-bearing structures

- Robust and highly durable

7. ISMC MS E250A Channels

- Lower strength grade

- Suitable for lighter construction needs

- More economical

8. ISMC Mild Steel E250BR Channel

- Similar to E250A but with enhanced structural properties

- Good for moderate load-bearing structures

- Affordable yet reliable

Each of these grades caters to specific requirements, from light-duty to heavy-duty structural applications. Whether you’re involved in construction, manufacturing, or industrial projects, there is an ISMC MS channel grade that fits your needs perfectly.

ISMC Weight Chart Per Meter and Kg

|

Type

|

Weight per meter (kg) |

Depth of Section (mm) |

Sectional area (cm²) |

Thickness of Flange (mm) |

Width of Flange (mm) |

Thickness of web (mm) |

| ISMC 75 |

6.8 |

75 |

8.67 |

7.3 |

40 |

4.4

|

|

ISMC 100

|

9.2 |

100 |

11.70 |

7.5 |

50 |

4.7 |

| ISMC 125 |

12.7 |

125 |

16.19 |

8.1 |

65 |

5.0

|

|

ISMC 150

|

16.4 |

150 |

20.88 |

9.0 |

75 |

5.4 |

| ISMC 175 |

19.1 |

175 |

24.38 |

10.2 |

75 |

5.7

|

|

ISMC 200

|

22.1 |

200 |

28.21 |

11.4 |

75 |

6.1 |

| ISMC 225 |

25.9 |

225 |

33.01 |

12.4 |

80 |

6.4

|

|

ISMC 250

|

30.4 |

250 |

38.67 |

14.1 |

80 |

7.1 |

| ISMC 300 |

38.8 |

300 |

45.64 |

13.6 |

90 |

7.6

|

|

ISMC 350

|

42.1 |

350 |

53.66 |

13.5 |

100 |

8.1 |

| ISMC 400 |

49.4 |

400 |

62.93 |

15.3 |

100 |

8.6

|

ISMC Channel Weight Chart and Sizes

When dealing with ISMC (Indian Standard Medium-weight Channel) steel channels, it’s essential to understand their weight and size specifications. Below is a detailed weight chart for various ISMC channel sizes:

Size (mm) Weight (Kg/m) MC 40 x 32 x 5 4.82 MC 75 x 40 x 4.8 7.14 MC 100 x 50 x 5 9.56 MC 125 x 65 x 5.3 13.10 MC 150 x 75 x 5.7 16.80 MC 200 x 75 x 6.2 22.30

Key Points:

- MC 40 x 32 x 5: Weighs 4.82 kg per meter, ideal for lightweight structures.

- MC 75 x 40 x 4.8: Weighs 7.14 kg per meter, suitable for medium-duty applications.

- MC 100 x 50 x 5: Weighs 9.56 kg per meter, commonly used for robust framing.

- MC 125 x 65 x 5.3: Weighs 13.10 kg per meter, perfect for heavy-duty construction.

- MC 150 x 75 x 5.7: Weighs 16.80 kg per meter, excellent for high-strength requirements.

- MC 200 x 75 x 6.2: Weighs 22.30 kg per meter, best for industrial-grade infrastructures.

Ensure you select the right channel size and weight for your specific application to guarantee structural integrity and performance.

How Does the ISMC Weight Chart Aid in Structural Drawing?

The ISMC weight chart serves as a crucial tool for structural designers by providing detailed information on the load-bearing capacities and dimensions of ISMC channels. This data allows designers to:

- Choose the Right Material: Ensure the selected ISMC channel meets the project’s load requirements.

- Guarantee Safety: Verify that the structure can safely support the anticipated loads.

- Enhance Durability: Select channels that will contribute to the long-term stability and strength of the structure.

By referencing the weight chart, designers can make informed decisions, ultimately leading to safer and more durable construction projects.

The Role of Standardization in the ISMC Weight Chart

Standardization is crucial in the ISMC weight chart as it ensures consistent quality and uniformity across the board. By adhering to Indian Standard specifications, the chart provides a reliable reference for selecting the appropriate channel for your construction needs.

Here are the key benefits of this standardization:

- Quality Assurance: Standardization ensures that every product meets a consistent quality level, making it easier to trust and use these materials in your projects.

- Uniformity: With standardized measurements, you can expect uniform properties, making it easier to plan and execute your construction projects without unexpected variables.

- Ease of Selection: The ISMC weight chart simplifies the selection process, guiding you to choose the right channel based on the specific requirements of your project.

In summary, standardization in the ISMC weight chart is essential for maintaining homogeneity, ensuring quality, and simplifying the selection process in the construction industry.

How Does the ISMC Weight Chart Ensure Adaptability in Construction?

The ISMC weight chart is a crucial tool in construction, providing engineers with detailed specifications for various channels. This comprehensive guide assists in identifying the right ISMC channels for different structural applications. Here’s how:

Precision in Selection

Engineers can easily match specific project requirements with precise ISMC channels, ensuring optimal performance and safety. This allows for precise load calculations and material selection.

Effortless Compatibility

The chart’s detailed information facilitates seamless integration of structural components. Channels can be joined correctly and effortlessly, minimizing errors in construction.

Versatility in Application

From bridges to buildings, the ISMC weight chart covers a wide range of applications, making it a versatile resource. Engineers can swiftly adapt to diverse construction needs with confidence.

Streamlined Construction Process

By providing clear and concise data, the ISMC weight chart streamlines the construction process. This efficiency reduces downtime and accelerates project timelines.

In summary, the ISMC weight chart is an essential tool that enhances adaptability in construction, ensuring that engineers can select and utilize channels with precision and ease.

How to calculate the weight of the mild steel channel?

Mild Steel channel are U- shaped structure made of steel defined by dimension of its sides and thickness. Mild steel channel have two parts flange and web base and horizontal part of it is known as flange and top vertical part of it is known as web.

It has unequal sides for example 100×50×5 mm, both the sides’ web and flange of Mild Steel channel are 100 and 50 mm and their thickness is of 5 mm.

Mild Steel Channel Weight in kg per Meter

- MS Web Volume

- MS Channel Size = 100×50×5 mm

- Web Depth = 100 mm =0.1m

- Web Thickness = 5 mm=0.005 m

- Web Length = 1 m

- Volume = l×b×h

- Volume = 0.1×0.005×1 m3

- Web Volume = 0.0005 m3

How to Calculate the Weight of Structural Steel ISMC Channels?

To determine the weight of structural steel ISMC channels, follow this formula:

Weight Calculation Formula:

[ text{Weight (kg/m)} = (A – B) times C times D ]

Where:

- A = Flange Width (in millimeters)

- B = Flange Thickness (in millimeters)

- C = Width of the Web (in millimeters)

- D = Thickness of the Web (in millimeters)

Step-by-Step Guide:

- Measure the Flange Width (A):

- The overall width of the flange from one edge to the other.

- Determine the Flange Thickness (B):

- The thickness of the outer edges of the steel channel.

- Identify the Width of the Web (C):

- The vertical section connecting the two flanges.

- Find the Thickness of the Web (D):

- The thickness of the vertical section between the flanges.

Example Calculation:

Given:

- Flange Width (A) = 100 mm

- Flange Thickness (B) = 10 mm

- Width of the Web (C) = 50 mm

- Thickness of the Web (D) = 6 mm

Substitute these values into the formula:

[ text{Weight (kg/m)} = (100 text{ mm} – 10 text{ mm}) times 50 text{ mm} times 6 text{ mm} ]

[ text{Weight (kg/m)} = 90 text{ mm} times 50 text{ mm} times 6 text{ mm} ]

Final Calculation:

[ text{Weight (kg/m)} = 27000 text{ mm}^3 ]

To convert to kilograms per meter, factor in the density of steel (approx. 7.85 g/cm³) and convert units accordingly.

By following these steps, you can precisely compute the weight of any ISMC channel you’re working with, essential for accurate project planning and execution.

Specifications for IS 2062 Mild Steel C Channel as per IS 808 Code

Product Types:

- Mild Steel C Channels

- IS 2062 Structural Steel Channels

Shape:

Size Range:

- From 75 x 40 mm to 400 x 100 mm

Length Options:

- 3 meters

- 5 meters

- 6 meters

- 8 meters

- 12 meters

Indian Standard Codes:

- IS 808 for dimensional standards

- IS 852 for specific dimensions

- IS 1852 and IS 3954 for tolerances

Grades Available:

- IS 2062 Mild Steel (MS)

- IS 2062 E250/ E250A

- IS 2062 E275

- IS 2062 E300

- IS 2062 E350/ E350BR

- IS 2062 E410

- IS 2062 E450

- IS 2062 E550

- IS 2062 E600

Quality Grades:

International Standards Compatibility:

- ASTM A36

- ASTM A572

- EN 10025-2

Manufacturing Method:

Applications:

- Structural Applications

- Frame Design for Trucks/Trailers

- Industrial Sheds

- Bridges

- Railway Masts

- Refineries

Country of Origin:

Weight per Unit Length:

Leading Manufacturers:

- Steel Authority of India Limited (SAIL)

- Jindal Steel and Power Limited (JSPL)

- Visakhapatnam Steel Plant (VSP)

- ESSAR

The IS 2062 Mild Steel C Channels adhere to these specifications to ensure consistency, quality, and performance across various structural and construction applications.

ISMB Weight Chart And ISMC Weight Chart.

ISMB Weight Chart

Understanding the unit weight of steel in civil engineering is critical when working with structural materials. Common terms used are ISMC and ISMB, with ISMC standing for “Indian Standard Medium Weight Channels” and ISMB for “Indian Standard Medium Weight Beams,” helping classify steel sections based on size and load-bearing capacities. calculate the unit weight in kg/m one can use this formula: (Steel weight per meter x Length of bar in meters / weight per kg per meter )/(Steel weight per Meter * Length of Steel Bar in meters) = (Steel weight per Meter * Length of Bar in meters) * 1.58 =0.395 kg/m. For instance if we had a 32 mm steel bar of 12 meters length that weighted 1.58 kg per meter its unit weight would equal to 0.395% kg/m.

ISMB beams play an essential part in building sturdy frameworks for buildings and bridges. An ISMB 350 beam, known for its robustness and load-bearing capacity, may vary in its unit weight depending on its dimensions and length; using the steel bars formula, one 12m long ISMB 350 beam has been calculated at 0.617 kg/m using steel bars formula calculations; this information helps engineers and architects in determining overall weight distribution and structural stability for projects.

How to Calculate the Unit Weight of an ISMC 100 Channel

Calculating the unit weight of an ISMC 100 channel involves a straightforward formula based on volume and density. Here’s a step-by-step guide:

Formula: [ text{Weight} = text{Volume} times text{Density} ]

Components:

- Volume (V): The amount of space the ISMC 100 channel occupies.

- Density (D): The mass per unit volume of the material used for the channel.

Step-by-Step Calculation:

- Determine the Volume: Measure or obtain the dimensions of the ISMC 100 channel. Use these dimensions to calculate the volume.

- If you have the cross-sectional area (A) and the length (L) of the channel, multiply them: [ V = A times L ]

- Find the Density: Look up the material density. Steel, for example, typically has a density of approximately 7.85 g/cm³ or 7850 kg/m³.

- Multiply Volume by Density: Use the values obtained for volume and density in the formula. [ text{Weight} = V times D ]

Example Calculation:

- Assume Dimensions:

- Cross-sectional area (A) = 20 cm²

- Length (L) = 100 cm

- Calculate Volume: [ V = A times L = 20 , text{cm}² times 100 , text{cm} = 2000 , text{cm}³ ]

- Use Density of Steel: [ D = 7.85 , text{g/cm}³ ]

- Compute Weight: [ text{Weight} = 2000 , text{cm}³ times 7.85 , text{g/cm}³ = 15700 , text{g} = 15.7 , text{kg} ]

By following these steps, you can accurately determine the unit weight of an ISMC 100 channel based on its volume and the density of the material used.

MS channel size

We know that MS channel consist of flange and web, it comes in several sizes ranging between 75×40×4.8 mm to 400× 100× 8.8 mm. Weight of MS channel is calculated in Kg per meter or in Kg per feet. Clearly higher dimension will have higher weighted value and lower dimension have lower weight value.

For example MS channel having dimension 100×50×5 mm

Mild Steel Channel Unit Weight

Unit weight of MS channel calculated by formula weight = volume × density & density of steel is 7850 Kg/m3 and volume is calculated by multiplying web height × flange width × thickness.

MS channel Total volume

- Total volume = volume of flange+ volume of web

- Total volume = 0.000450 +0.0005 m3

- Total volume =0.000950m3

- 4) Weight of MS channel

- Weight = volume× density

- Volume = 0.000950 m3

- Density of steel = 7850 kg/m3

- Weight = 0.000950m3×7850 kg/m3

- Weight of MS channel = 7.45 kg/m

- Ans: MS channel unit weight will be 7.45 kg

Two flange Volume

- MS Channel Size = 100×50×5 mm

- Flange Width = 50_5 mm =45mm=0.045 m

- Flange Thickness = 5 mm=0.005 m

- Flange Length = 1 m

- Volume = L×B×H

- Volume = 0.045×0.005×1 m3

- Flange Volume = 0.000225 m3

- Two Flange Volume = 0.000225×2 m3

- Two Flange Volume of = 0.000450 m3

How the ISMC Weight Chart Aids in Material Measurement and Size Evaluation

The ISMC weight chart is a crucial tool for those involved in construction, manufacturing, and logistics. By referencing this chart, you can accurately determine the weight of various structural components, which is essential for several reasons:

- Precise Weight Calculation: The chart offers exact measurements, ensuring you know the total weight of the structure. This is vital for planning and resource allocation.

- Easy Handling: Knowing the weight in advance helps in strategizing the transportation and handling of materials, reducing the risk of damage or accidents.

- Cost Estimation: Accurate weight information supports better financial planning, enabling precise estimation of material costs and budgeting.

In summary, the ISMC weight chart streamlines the process of material measurement and size evaluation, making your projects more efficient and cost-effective.

ISMB Weight Chart And ISMC Weight Chart.

Why Choose Us?

Working in the industry for a decade now, we have always followed severe internal standards and quality procedures to make sure that we always deliver the best. We are also known for our advanced pricing structure.

MS Channels are mainly used in the construction of trucks, trolleys, cranes, ships, containers, bridges, parking lots, etc. Its extensive use in several constructions makes it an integral part of the structure. Knowing its importance as mild steel channel suppliers, we make sure that all of our products are built to give strength, support, and durability to the construction. Sachiya Steel International is one of the well-known mild steel channel suppliers in India.

ISMC and ISMB beams are prominent terms in civil engineering, representing steel sections with specific load-bearing characteristics. Calculating their unit weight is a core task in design and construction engineering; using appropriate formulae such as those mentioned earlier allows engineers to accurately ascertain these values when planning and executing construction projects.

Why the ISMC Weight Chart is Valuable for Architects and Engineers

The ISMC weight chart is an indispensable tool for structural designers and engineers. Here’s why:

- Load-Bearing Capacity and Sizes:

- The chart helps in selecting the suitable ISMC channel based on the desired load-bearing capacity and the dimensions of the structure. This is crucial for ensuring the safety and durability of your project.

- Material Measure and Project Estimation:

- The component weight information provided in the chart is essential for evaluating the entire weight of the structure. This assists in practical aspects like transportation, handling, and cost estimation.

- Standardization and Homogeneity:

- Following Indian Standard specifications, the chart assures homogeneity and standardization in the construction industry. This ensures consistent quality and reliability across projects.

- Ease of Selection and Application:

- The chart serves as a reference, helping customers and engineers to select the right channel based on project demands. Engineers can recognize suitable ISMC channels for attaching different structural elements, ensuring that the channels can be joined effortlessly and correctly.

By incorporating these details, the ISMC weight chart not only aids in precise calculations but also supports various practical aspects of construction engineering, making it an invaluable resource in the field.

| ms angle |

ms channel |

ms beam |

ms chain |

Trust Us With :

- Rust-proof Coat

- Strong and Sturdy Built

- Corrosion Free Channels

How Are ISMC Channels Manufactured?

ISMC (Indian Standard Medium Channels) are produced using a hot rolling process, adhering to the specifications outlined in the IS 808 code. This method involves heating steel billets until they become pliable and then shaping them into the desired channel forms using rollers.

Steps in the Manufacturing Process:

- Selection of Raw Material: Steel billets, typically of the MS (Mild Steel) variety, are chosen based on their grade and quality. Common grades include E 250, E 275, E 300, E 350, and E 410.

- Heating: The steel billets are heated in a furnace to a temperature where they become malleable.

- Hot Rolling: These heated billets are passed through a series of rollers that shape them into the standard ISMC profile. The dimensions and tolerances are maintained according to the IS 808 specifications.

- Cooling: Once the desired shape is achieved, the channels are slowly cooled to room temperature. This ensures that the structural integrity of the channel is retained.

- Quality Control: Post-production, the channels undergo rigorous quality checks. Tests are conducted to ensure they meet the required standards in terms of dimensions, strength, and durability.

Leading Manufacturers:

Several prominent manufacturers in India produce ISMC Channels. Key players include:

- SAIL (Steel Authority of India Limited)

- JSPL (Jindal Steel & Power Limited)

- ESSAR Steel

- VSP (Visakhapatnam Steel Plant)

Each of these manufacturers adheres to stringent quality standards to produce reliable and robust ISMC Channels suitable for a variety of construction and engineering applications.

By following this meticulous process, manufacturers ensure that ISMC Channels meet both national and international standards, making them a preferred choice in the industry.

Weight Chart for ISMC Mild Steel Channels

Understanding the specifications of ISMC mild steel channels is crucial for selecting the right material for your needs. Below is a detailed weight chart for ISMC mild steel channels manufactured by some leading providers:

Specifications Overview:

Grade Web Depth Flange Width Sectional Weight E350BR, E410A, E250A, E410BR, E300A, E350A 75-300 mm 40-90 mm 7.14 – 36.3 kg/m Different Grades 75-400 mm 40-100 mm 7.14 – 50.1 kg/m Another Range of Grades 40-200 mm 32-75 mm 4.82 – 22.3 kg/m Manufacturer-Specific Details:

- SAIL Channels

- Web Depth: Ranges from 75 mm to 300 mm

- Flange Width: Between 40 mm and 90 mm

- Sectional Weight: 7.14 kg/m to 36.3 kg/m

- JSPL Channels

- Web Depth: Ranges from 75 mm to 400 mm

- Flange Width: Between 40 mm and 100 mm

- Sectional Weight: 7.14 kg/m to 50.1 kg/m

- VSP Channels

- Web Depth: Ranges from 40 mm to 200 mm

- Flange Width: Between 32 mm and 75 mm

- Sectional Weight: 4.82 kg/m to 22.3 kg/m

This information helps you compare the different specifications available across various manufacturers, ensuring you can make an informed decision for your structural requirements.

ISMC Weight Chart

MS Channel prices vary according to its sizes. We offer them in all standard sizes and shapes. ISMB Weight Chart And ISMC Weight Chart. One can trust us with quality as the offered channels are manufactured under the keen supervision of highly-skilled professionals and produced using high-grade materials. We also provide mild steel channels according to the customer’s requirements.

Introduction to Indian Standard

The Indian Standard (IS) is a comprehensive set of guidelines developed by the Bureau of Indian Standards (BIS) to ensure the quality, safety, and reliability of products used across various industries in India. In the realm of steel construction, these standards are particularly significant for defining the properties and dimensions of steel sections such as Indian Standard Medium Weight Beams (ISMB) and Indian Standard Medium Weight Channels (ISMC). By adhering to the Indian Standard, manufacturers produce steel sections that meet strict criteria for strength, durability, and dimensional accuracy, which are essential for the structural integrity of buildings and infrastructure.

For engineers, architects, and construction professionals, understanding and utilizing steel sections that comply with the Indian Standard is crucial. It guarantees that ISMB beams and ISMC channels will perform as expected under load, fit seamlessly into standardized designs, and contribute to the overall safety of the project. The Indian Standard not only streamlines the selection process for steel sections but also ensures compatibility and interchangeability across different manufacturers and suppliers, making it a cornerstone of modern construction practices in India.

Flange Volume

Flange volume is a key factor in determining the overall weight and structural performance of mild steel channels, including ISMC and ISMB sections. The flange refers to the horizontal part of the channel, and its dimensions—specifically the flange width and flange thickness—directly impact the channel’s ability to bear loads and resist bending.

When calculating ms channel weight or c channel weight, the volume of the flange is combined with the web volume to arrive at the total sectional weight. A larger flange width or increased flange thickness results in a higher flange volume, which in turn increases the channel’s weight and its load-bearing capacity. This is particularly important in applications where channels are subjected to significant horizontal gravitational forces or need to support heavy loads.

Understanding flange volume is essential for engineers and designers, as it allows for precise weight calculations and ensures that the selected channel meets the structural requirements of the project. By referencing detailed weight charts and considering flange dimensions, professionals can optimize their material choices for both performance and cost-effectiveness.

Construction Materials

The choice of construction materials plays a pivotal role in the performance and longevity of ISMB beams and ISMC channels. Mild steel is the most commonly used material for these steel sections due to its excellent balance of strength, ductility, and cost-effectiveness. High grade materials are selected to ensure that the channels and beams can withstand demanding load-bearing applications and harsh environmental conditions.

To further enhance durability, many mild steel channels are treated with a rust-proof coat, making them strong and resistant to corrosion. This is especially important for structures exposed to moisture or outdoor environments. Leading mild steel channel suppliers adhere to strict quality standards, ensuring that every batch of building material meets the specifications set by the Indian Standard.

In addition to mild steel, some manufacturers may offer specialized alloys or coatings to meet unique project requirements. Regardless of the material, the focus remains on delivering steel sections that are reliable, consistent, and capable of supporting the structural needs of modern construction.

Conclusion and Future Outlook

The ISMB weight chart and ISMC weight chart have become indispensable tools for professionals in the construction and engineering industries. By providing a detailed weight chart and standardized dimensions, these resources enable accurate planning, efficient material usage, and cost-effective project execution. As the demand for advanced pricing structures and precise weight calculation formulas grows, the industry continues to evolve with digital tools and software that make accessing and utilizing these charts even easier.

Looking ahead, the future of steel sections in India is set to benefit from ongoing advancements in manufacturing technology, stricter quality control, and the adoption of international best practices. As structural requirements become more complex and sustainability gains importance, the role of standardized, high-quality steel sections will only increase. Professionals can expect even more refined sectional weight charts, improved materials, and innovative solutions to meet the challenges of tomorrow’s construction projects.

Final Thoughts on Indian Standard Medium Weight

Indian Standard Medium Weight sections, including ISMB beams and ISMC channels, are the backbone of modern construction in India. Their standardized dimensions, reliable performance, and widespread availability from trusted mild steel channel suppliers make them the preferred choice for a wide range of structural applications. By adhering to the Indian Standard, the industry ensures that every project benefits from consistent quality, safety, and efficiency.

Whether you are an engineer, architect, or builder, relying on standard medium weight beams and channels means you can approach your projects with confidence, knowing that your materials meet the highest benchmarks for strength and durability. As the construction landscape continues to advance, the importance of these standardized steel sections will remain central to building safe, resilient, and innovative structures across the country.