MS Chequered Plate Weight Per Square Meter : The Complete Guide

Understanding the weight of MS Chequered Plate is a critical factor for any project, influencing everything from structural design and load-bearing capacity to shipping costs and budget estimation.

In India, these plates are widely known as “Chakkar Plate” or “Chq Plate,” while internationally, you’ll hear them called “Tread Plate“ or “Diamond Plate.” Regardless of the name, their function is the same: to provide a durable, anti-skid surface for flooring, stairs, and walkways.

As a premier manufacturer and exporter, Sachiya Steel International Private Limited has created this definitive guide to provide you with the accurate data you need. Here, you will find a precise weight calculator, comprehensive charts, and clear specifications.

MS Chequered Plate Weight Calculator

For a quick and accurate calculation of your total requirement, use our interactive weight calculator. Simply enter your dimensions to get the total weight instantly. This tool uses industry-standard nominal weights for the highest accuracy.

MS Chequered Plate Weight Calculator

Total Estimated Weight:

0.00 kg

MS Chequered Plate Weight Per Square Meter (kg/m²)

This chart is the fastest way to find the unit weight for standard MS chequered plate thicknesses. The “Nominal Weight” is the accepted industry standard, which includes the weight of the base plate plus the raised pattern.

| Thickness (mm) | Nominal Weight (kg/m²) |

| 3 mm | 26.55 kg/m² |

| 4 mm | 34.40 kg/m² |

| 5 mm | 42.25 kg/m² |

| 6 mm | 50.10 kg/m² |

| 8 mm | 65.80 kg/m² |

| 10 mm | 83.40 kg/m² |

| 12 mm | 100.60 kg/m² |

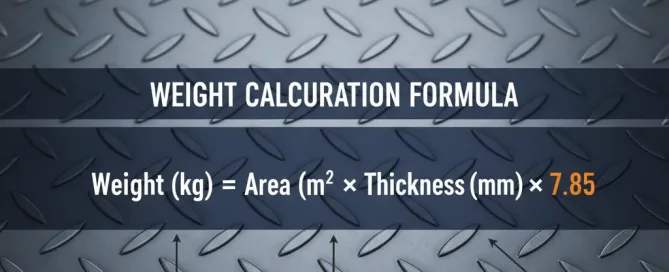

How to Calculate MS Chequered Plate Weight (Formula)

While charts are fast, you may need to understand the basic formula. The weight of any steel plate is its volume multiplied by its density.

-

Density of Mild Steel (MS): 7850 kg/m³

A simple formula for a flat MS plate is:

Weight (kg) = Area (m²) × Thickness (mm) × 7.85

Why This Formula Can Be Misleading

If you use this formula for a 6mm plate:

1 m² × 6 mm × 7.85 = 47.1 kg

Notice this is less than the 50.10 kg/m² in our chart. Why?

The formula calculates the weight of the flat base plate only. It does not include the extra material used to create the raised “chequers” or “diamonds.” The Nominal Weight (50.10 kg/m²) is the correct, accepted weight to use for all project planning and costing.

Nominal vs. Theoretical Weight: A Key Comparison

This table clarifies the difference. “Theoretical Weight” is the simple formula for a flat plate, while “Nominal Weight” is the industry-standard weight for the finished chequered plate.

| Thickness (mm) | Theoretical Weight (kg/m²) (Flat Plate Only) | Nominal Weight (kg/m²) (Chequered Plate) |

| 3 mm | 23.55 kg/m² | 26.55 kg/m² |

| 4 mm | 31.40 kg/m² | 34.40 kg/m² |

| 5 mm | 39.25 kg/m² | 42.25 kg/m² |

| 6 mm | 47.10 kg/m² | 50.10 kg/m² |

| 8 mm | 62.80 kg/m² | 65.80 kg/m² |

| 10 mm | 78.50 kg/m² | 83.40 kg/m² |

| 12 mm | 94.20 kg/m² | 100.60 kg/m² |

MS Chequered Plate Specifications

As a leading supplier, Sachiya Steel International provides plates that meet stringent international standards.

| Attribute | Specification |

| Grades | IS 2062 (E250, E350), ASTM A36, BS4360 43A |

| Standard Thickness | 3 mm to 12 mm |

| Standard Width | 1250 mm, 1500 mm, 2000 mm |

| Standard Length | 2500 mm, 5000 mm, 6000 mm |

| Technique | Hot Rolled (HR) |

| Patterns | 5-Bar (Lentil) & 1-Bar (Teardrop / Diamond) |

| Applications | Industrial Flooring, Stair Treads, Truck Beds, Ramps |

Weight of a Standard 4×8 Steel Diamond Plate

“4×8” (4 feet by 8 feet) is a very common plate size, especially in the US market. This chart shows the weight per sheet.

(Note: 1 foot = 0.3048 meters. A 4×8 ft plate is 1.219m x 2.438m ≈ 2.97 m²)

| Thickness | Weight per 4×8 Sheet (kg) |

| 3 mm | ~ 78.9 kg |

| 5 mm | ~ 125.5 kg |

| 6 mm | ~ 148.8 kg |

| 8 mm | ~ 195.4 kg |

Chequered Plate Weight Per Square Foot (lbs)

For our international clients or projects using imperial units, this table converts the weight to pounds (lbs) per square foot.

| Thickness (Inches) | Approx. Thickness (mm) | Weight (lbs / sq. ft) |

| 1/8″ | 3.175 mm | ~5.4 lbs |

| 3/16″ | 4.76 mm | ~7.0 lbs |

| 1/4″ | 6.35 mm | ~9.2 lbs |

| 3/8″ | 9.525 mm | ~13.5 lbs |

| 1/2″ | 12.7 mm | ~17.1 lbs |

Why Choose Sachiya Steel International?

When sourcing MS Chequered Plates, quality, accuracy, and reliability are paramount.

Sachiya Steel International Private Limited is not just a stockholder; we are a premier manufacturer, supplier, and exporter based in Mumbai, India.

-

Certified Quality: We provide MS Chequered Plates conforming to IS 2062 and other international standards, complete with Mill Test Certificates (MTC).

-

Large Inventory: We maintain a massive stock of all common sizes and thicknesses for immediate dispatch.

-

Custom Cutting: We offer precision cutting services to match your exact project dimensions, saving you time and reducing waste.

-

Global Export: We have a proven track record of exporting our products worldwide, with all logistics and documentation handled by our expert team.

Don’t let guesswork define your project. Get the exact materials you need with the certified quality you deserve.

For the latest prices, a custom quote, or technical advice, contact our expert team today.

-

Phone: +91 9769056007

-

Email: [email protected] / [email protected]

-

Address: Office No 102, 1st Floor, Prasad Chambers, Tata Rd No 2, Opera House, Girgaon, Mumbai, Maharashtra 400004

What is the weight of 6mm chequered plate?

The standard nominal weight of a 6mm MS chequered plate is 50.10 kg per square meter. A full 8ft x 4ft (1.2m x 2.4m) sheet of 6mm chequered plate weighs approximately 148.8 kg.

What is the unit weight of 8mm chequered plate?

The unit weight (or weight per square meter) of an 8mm MS chequered plate is 65.80 kg/m².

What is the difference between chequered plate and tread plate?

There is no difference. "Chequered Plate" (and "Chakkar Plate" in India) and "Tread Plate" (or "Diamond Plate" in the USA) are different regional names for the same product—a steel plate with a raised pattern to provide anti-skid properties.

What is the weight of 5mm chequered plate?

The nominal weight of a 5mm MS chequered plate is 42.25 kg per square meter.