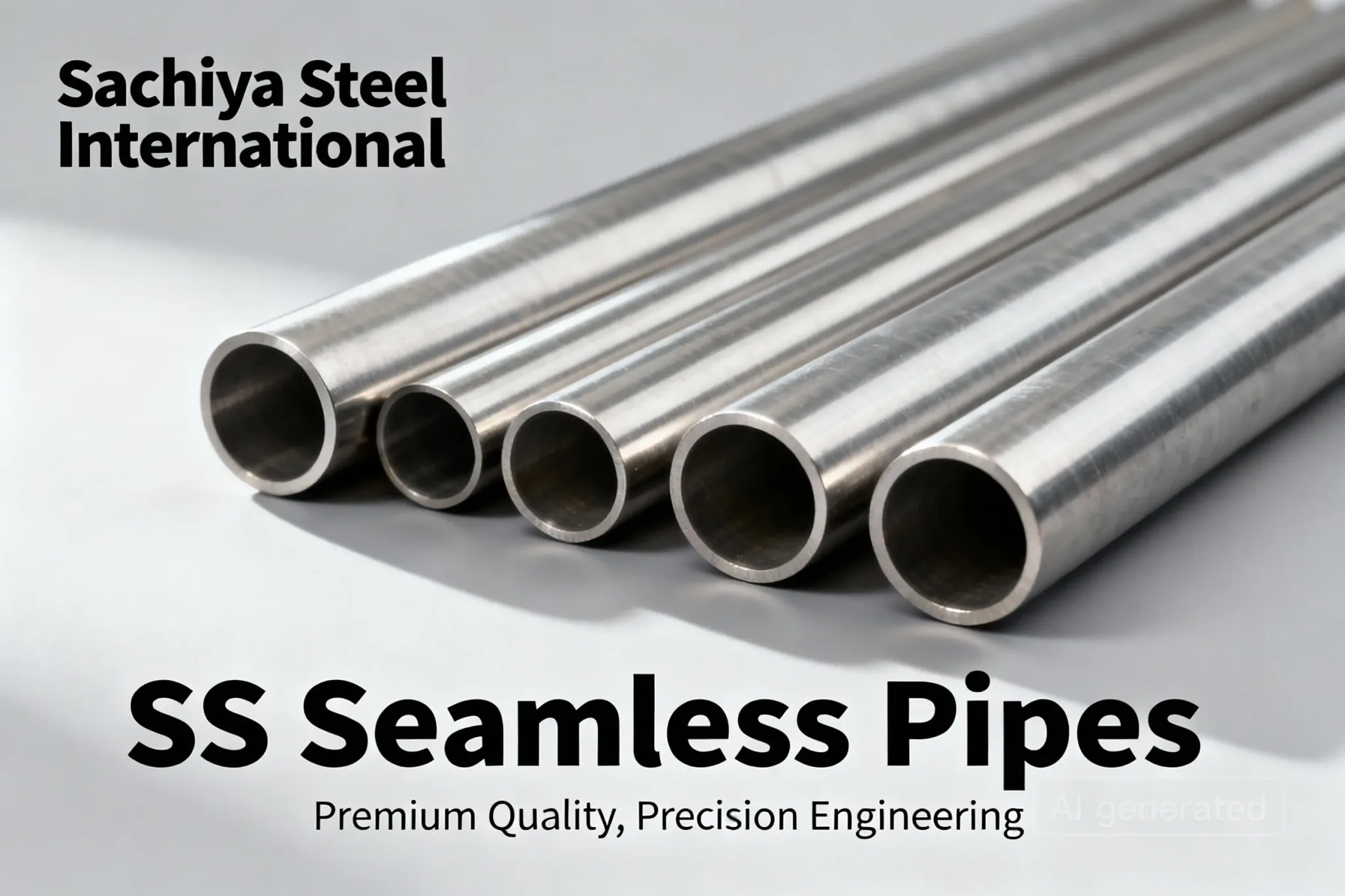

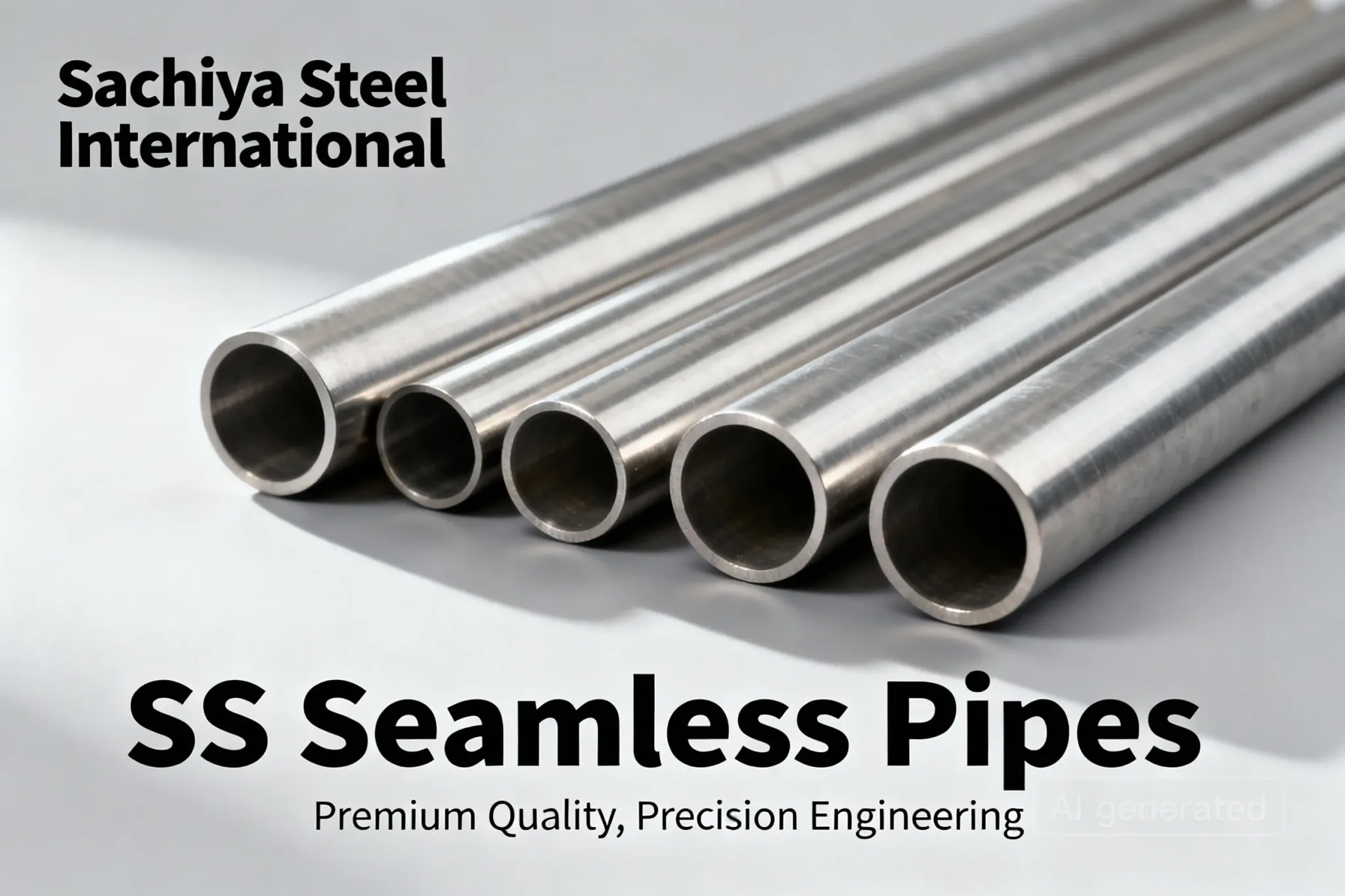

Stainless Steel Seamless Pipe Manufacturers In India

Sachiya Steel International Private Limited stands out as a premier seamless pipe manufacturers in India, thanks to our dedication to quality and cutting-edge technology. Every seamless pipe we produce bears the hallmark of excellence; when you choose Sachiya Steel International as your seamless pipe supplier, you are selecting not just a manufacturer; instead you are selecting reliability and durability in every inch of its seamless pipe production. With extensive expertise in the manufacture of stainless steel seamless pipes, Sachiya Steel International utilizes advanced manufacturing facilities and technical capabilities to deliver superior products.

In India the top carbon steel and seamless steel alloy pipe producers include Jindal SAW, Maharashtra Seamless Limited, Ratnamani Pipes & Tubes and ISMT. We are equipped to cater to specific customer requirements, offering customized solutions, customer-supplied raw materials, and minimum order quantities for specialized applications. In the case of stainless steel, based on our estimates, 70 percent of the items are imported, due to the huge costs for making in India. There are different types of stainless steel pipes available, including seamless, welded, and ERW pipes, manufactured in various standards such as ASTM and ASME, and a wide range of sizes to meet diverse industrial needs. Our prices for seamless pipes in India start at just ₹120 per kilogram, ensuring that you receive the highest quality products at a highly competitive rate.

Stainless Steel Seamless Pipe Manufacturers In India

Below is a list of the top high-end Seamless Pipe Manufacturers In India and carbon steel pipe manufacturer in india. For immediate delivery or factory-priced seamless pipe please get in touch with Sachiya Steel International Private Limited. With our vast inventory of raw materials, we can offer tailored solutions to meet each customer’s specific requirements, and our daily sales exceeding 250 tones allow us to give you the best price as well as lower cost of the factory directly.

| Jindal SAW Ltd |

India |

|

Maharashtra Seamless Ltd.

|

India |

| ISMT |

Pune

|

|

Ratnamani Pipes & Tubes

|

India

|

Sachiya Steel International and the companies listed above are recognized as leading tubes manufacturers in India, with expertise in producing both pipes and tubes for a wide range of industries including marine, petroleum, power, and construction.

Introduction to Stainless Steel

Stainless steel is a highly versatile and durable alloy, renowned for its exceptional corrosion resistance and strength. This unique combination of properties makes stainless steel an essential material across a wide range of industries, including construction, aerospace, manufacturing, and more. Stainless steel pipes and tubes are especially valued for their ability to withstand harsh environments, high pressures, and demanding operational conditions, ensuring long-lasting performance and safety.

As a leading manufacturer and supplier of stainless steel pipes and tubes in India, companies such as Oshwin Overseas, Nisco Steel India, Rashmi Seamless, and Divine Tubes Pvt. Ltd are committed to delivering products that meet stringent international standards. Their stainless steel pipes and tubes are manufactured using advanced processes and high-quality materials, resulting in products that offer superior durability, reliability, and corrosion resistance. Whether used in construction projects, industrial plants, or aerospace applications, stainless steel pipes and tubes provide the strength and performance required for critical operations. The wide range of available grades, sizes, and specifications ensures that customers can find the perfect solution for their specific needs, making stainless steel a preferred choice for industries seeking quality and longevity.

Types of Pipes

The world of industrial piping offers several types of pipes, each designed to meet specific application requirements. The most common categories include seamless pipes, welded pipes, and ERW (Electric Resistance Welded) pipes.

Seamless pipes are produced by piercing a solid billet of steel and then extruding it into a hollow tube, resulting in a product with no seams or welds. This seamless construction provides superior strength, uniformity, and resistance to cracking, making stainless steel seamless pipes ideal for high-pressure and high-temperature environments. Manufacturers like Rashmi Seamless are known for producing stainless steel seamless pipes that deliver outstanding durability and corrosion resistance, ensuring reliable performance in demanding applications.

Welded pipes are created by joining two pieces of metal together along a seam using various welding techniques. While welded pipes are suitable for many applications, the presence of a seam can make them less suitable for certain high-pressure or corrosive environments compared to seamless pipes.

ERW pipes are manufactured using an electric resistance welding process, where the edges of steel strips are fused together using electric current. This method produces pipes with a consistent wall thickness and smooth finish, suitable for a variety of structural and low-pressure uses.

Each type of pipe—seamless, welded, and ERW—offers distinct advantages depending on the intended use. Stainless steel seamless pipes, in particular, are favored for their high strength, excellent corrosion resistance, and suitability for critical, high-pressure applications in industries such as oil and gas, chemical processing, and power generation.

Pipes and Tubes

Pipes and tubes are fundamental components in the transport of fluids, gases, and other materials across a wide range of industries. While both are cylindrical in shape, they can differ in terms of dimensions, wall thickness, and intended applications. Stainless steel pipes and tubes are especially popular due to their outstanding corrosion resistance, strength, and durability, making them suitable for use in harsh environments and demanding industrial processes.

Available in a variety of materials—including stainless steel, alloy steel, and carbon steel—pipes and tubes come in different shapes such as round, square, and rectangular, with a broad range of diameters and wall thicknesses to suit specific requirements. The wall thickness is a critical factor, as it determines the pipe or tube’s ability to withstand internal pressure and mechanical stress. Leading manufacturers like Divine Tubes Pvt. Ltd and Nisco Steel India offer stainless steel pipes and tubes in a wide array of dimensions and specifications, ensuring compatibility with diverse industry needs.

The manufacturing process for pipes and tubes involves several precise steps, including annealing to enhance ductility, pickling to remove surface impurities, and straightening to ensure dimensional accuracy. To guarantee the highest quality and performance, third party inspection and rigorous testing are conducted at various stages of production. This ensures that every pipe and tube meets international standards and detailed specifications for strength, corrosion resistance, and durability. Whether used in construction, chemical processing, or hydraulic systems, stainless steel pipes and tubes deliver reliable performance and long service life, making them a preferred choice for industries across India and around the world.

Seamless Pipe Manufacturing Process

Seamless steel pipes, an essential component in industries including oil and gas, are manufactured with extreme precision and quality control. Precise dimension control is critical in the manufacture of seamless pipes to ensure consistent quality, accurate sizing, and optimal performance in demanding applications. In contrast to welded pipes that feature visible weld seams, carbon steel seamless pipes are created without visible weld seams for complete homogeneity. Manufacturing processes typically begin with selecting high-grade raw materials, then cold drawing of pipes formed without seams for seamless operation and to ensure structural integrity and freedom from imperfections. The production of ss seamless pipes offers significant advantages for high-pressure applications due to their superior strength and absence of welds.

Specialized pipe mills rely on cutting-edge technology to refine dimensions and surface finish for superior products, while quality control measures play a vital role throughout production to guarantee reliable steel seamless tubes for critical applications. From raw material selection to final production, seamless pipes represent precision engineering excellence at its finest.

Steel pipes used in the oil and gas industry require considerable care in their manufacturing to ensure they’re strong yet smooth, without visible seams that would weaken them over time. We begin this process by selecting top-grade materials; next, a process known as cold drawing shapes them without seams for maximum strength while giving an ideal smooth surface finish.

Modern machines located within special pipe factories help ensure these seamless pipes reach just the desired dimensions with perfect sizing; finally we test each pipe throughout production to make sure they meet our highest quality expectations so we know they’re top quality enough for essential roles within oil & gas industries worldwide.

| Seamless Pipes |

Specifications |

|

|

|

|

Schedule

|

SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS |

|

|

|

| Standard |

ASME/ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799

|

|

|

|

|

Pipes Size

|

1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm |

|

|

|

| Type |

Seamless/ erw/ welded/semi welded in round, square, rectangular, coil form, u shape and hydraulic. Pipes

|

|

|

|

|

Grades

|

|

|

|

|

| Stainless Steel |

ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L

|

|

|

|

|

Super Duplex Steel

|

S32750 |

|

|

|

| Duplex Steel |

ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760.

|

|

|

|

|

Carbon Steel

|

ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

|

|

|

| Alloys Steel |

ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91.

|

|

|

|

|

Nickel Alloys

|

Nickel Alloys 200, Nickel Alloys 201 |

|

|

|

| Titanium |

Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI

|

|

|

|

|

Inconel

|

Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

|

|

|

| Hastelloy |

Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G

|

|

|

|

|

Molybdenum

|

ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum |

|

|

|

| Cobalt |

Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21

|

|

|

|

|

Niobium

|

ASTM B394, R04200 R04210 |

|

|

|

| Nimonic |

Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc

|

|

|

|

|

Tungsten

|

W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten |

|

|

|

| Nichrome |

Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc

|

|

|

|

|

Magnesium

|

Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. |

|

|

|

| Tantalum |

Tantalum – Grade 1.

|

|

|

|

|

Monel

|

Monel 400, Monel k500 |

|

|

|

| MU-METAL |

MU-METAL

|

|

|

|

|

Zirconium

|

Zirconium 702, Zirconium 705,Zirconium 705, Zirconium-2, Zirconium-4 |

|

|

|

| Beryllium Copper |

Alloy 25 UNSC17200

|

|

|

|

|

Aluminium

|

1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 |

|

|

|

| Copper Alloys |

C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000

|

|

|

|

Note: Pipes are also available in SCH XXS (extra extra strong) for high-pressure and specialized applications.

Also Read : SS 304 Price Per Kg

There are many top quality Seamless Pipe Manufacturers In India And around the world who offer Goods with full certifications and quicker responses. We can assist you in finding the highest quality pipe from the best supplier at a reasonable cost at any Seamless Pipe Manufacturers In India Or around the world.

|

Company Names

|

City / Country Names |

| Sachiya Steel International Private Limited |

Mumbai , India

|

|

Tenaris

|

Luxembourg |

| Vallourec |

France

|

|

JFE Steel Corporation

|

Japan |

| Nippon Steel & Sumitomo Metal Corporation |

Japan

|

|

TMK (Trubnaya Metallurgicheskaya Kompaniya)

|

Russia |

| ArcelorMittal |

Luxembourg

|

|

Schoeller-Bleckmann (SBO)

|

Austria |

| Tubacex |

Spain

|

|

Plymouth Tube Company

|

United States |

| Severstal |

Russia

|

|

Sandvik

|

Sweden |

|

Zhejiang Tsingshan Steel Pipe Co., Ltd

|

China

|

| Salzgitter Mannesmann Stainless Tubes |

Germany

|

|

Maharashtra Seamless Limited

|

Mumbai, India |

| Jindal SAW Ltd |

Mumbai, India

|

|

ISMT (Indian Seamless Metal Tubes)

|

Mumbai, India |

| Chengdu Derbo Steel Co., Ltd. |

China

|

|

Zhejiang Jinpu Alloy Steel Pipe Co., Ltd.

|

China |

| Tioga Pipe |

United States

|

|

Ameron Water Transmission Group

|

United States

|

We are leading Seamless Pipe Manufacturers In India. Our Seamless Pipes are available in different sizes, shapes, and grades. We supply these Pipes in most of the major Indian cities in more than 20 States. SS pipe and ss pipes are offered in a variety of grades and standards to meet diverse industrial requirements.

Buy Seamless Pipe Online or Call +91 22 66518863 or email at [email protected]

| Pipes according to ASTM A312 |

|

|

|

|

|

|

|

|

|

Grade

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

| TP 304 |

0.08 |

2.0 |

0.045 |

0.030 |

1.0 |

18.0-20.0 |

8.0-11.0

|

|

|

TP 304L

|

0.035 |

2.0 |

0.045 |

0.030 |

1.0 |

18.0-20.0 |

8.0-13.0 |

|

| TP 316L |

0.035 |

2.0 |

0.045 |

0.030 |

1.0 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0

|

| Note: For small diameter or thin walls or both, where many drawing passes are required, a Carbon maximum of 0.040% is necessary in grades TP 304L and TP 316L. Small outside diameter tubes are defined as those less than 0.50 in. [12.7 mm] in outside diameter and light wall tubes as those less than 0.049 in. [1.20 mm] in average wall thickness (0.044 in. [1.10 mm] in minimum wall thickness). |

|

|

|

|

|

|

|

|

Seamless Pipes may be furnished bare or coated and with capped ends. pipes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of Seamless Pipes may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.

Sachiya Steel International is an industry-leading Seamless Pipe Manufacturers In India specializing in producing premium grade alloy steel seamless pipes as well as stainless steel seamless pipes, meeting stringent industry standards with our state-of-the-art facilities and cold drawn seamless pipes of exceptional quality. Our range includes stainless steel pipe and stainless steel tubes, widely used in various industries and compliant with ASTM and ASME standards. Sachiya Steel International prides itself on offering exceptional durability, corrosion resistance and reliability with every product we make – one of India’s premier seamless pipe manufacturers, we ensure excellence tailored to meet the specific requirements of every project we work on! Experience excellence tailored to suit your needs with premium grade pipes; contact us now to learn more about our wide product offerings!

When comparing seamless and welded options, stainless steel seamless tubes provide superior strength and corrosion resistance due to their seamless construction, while welded tubes, though more cost-effective, may have a seam that is more susceptible to corrosion and cracking.

The mechanical properties of our pipes, including yield strength, are carefully tested to ensure each pipe can withstand deformation under load and meet the rigorous demands of industrial applications.

Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and Macro Test

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Documentation

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- Form A for the purposes of the Generalized System of Preferences (GSP)

Country’s We Export

Venezuela, Iraq, United Kingdom, Russia, United Arab Emirates, Croatia, Indonesia, Oman, Kazakhstan, Israel, Kenya, Iran, Bahrain, Bhutan, Colombia, Serbia, Pakistan, Czech Republic, Turkey, Ukraine, Poland, Bulgaria, France, Chile, Slovakia, Belgium, Iran, Ireland, Qatar, Sri Lanka, Sweden, Brazil, Bolivia, Taiwan, Jordan, South Africa, Switzerland, Tibet, Norway, India, Ghana, Costa Rica, Hungary, New Zealand, Vietnam, Ecuador, Afghanistan, Algeria, Peru, Netherlands, Argentina, Austria, Malaysia, Thailand, Portugal, Zimbabwe, Mongolia, Lebanon, Trinidad & Tobago, Tunisia, Mexico, Greece, Angola, Hong Kong, Denmark, Nepal, Finland, Chile, Poland, Yemen, Nigeria, Italy, Bangladesh, Australia, Macau, Azerbaijan, Saudi Arabia, Japan, Gabon, Philippines, Singapore, United States, Namibia, Romania, South Korea, Germany, Puerto Rico, Estonia, Morocco, Belarus, Nigeria, Mexico, Spain, China, Canada, Libya, Lithuania, Kuwait, Gambia, Egypt.

Seamless Pipe Manufacturers in Mumbai?

Some of the top seamless pipe manufacturers in Mumbai include:

1) Sachiya Steel International Pvt. Ltd. – A renowned name in the manufacturing of stainless steel and alloy steel seamless pipes.

2) Jindal SAW Ltd. – Known for its high-quality pipes used in oil and gas, power, and other industrial applications.

3) Maharashtra Seamless Ltd. – Specializes in seamless steel pipes with a focus on international standards and industrial usage.

4) ISMT Ltd. – Offers a wide range of seamless pipes made with the latest technology for various sectors.

These companies are recognized for producing durable and high-quality seamless pipes in Mumbai.

Top Seamless Pipe Manufacturers in India

India has several top manufacturers known for their seamless pipes:

1) Sachiya Steel International Pvt. Ltd. – Known for premium quality seamless pipes.

2) Jindal SAW Ltd. – One of the largest manufacturers of seamless pipes in India.

3) Maharashtra Seamless Ltd. – Specializes in high-quality carbon steel and alloy seamless pipes.

4) Ratnamani Pipes & Tubes Ltd. – Offers seamless pipes with excellent mechanical properties.

These manufacturers are recognized for their ability to provide durable and high-strength seamless pipes for various industrial applications.

Top 5 Seamless Pipe Manufacturers in India

The top 5 seamless pipe manufacturers in India are:

1) Sachiya Steel International Pvt. Ltd. – Offers premium quality seamless pipes in various grades.

2) Jindal SAW Ltd. – A leading manufacturer of seamless pipes for oil and gas, power, and more.

3) Maharashtra Seamless Ltd. – Known for a strong focus on seamless pipes with global standards.

4) ISMT Ltd. – A manufacturer specializing in seamless tubes and pipes for critical applications.

5) Ratnamani Pipes & Tubes Ltd. – Renowned for high-strength seamless steel pipes.

These companies ensure high-quality manufacturing, timely deliveries, and compliance with international standards.

List of Seamless Pipe Manufacturers in India

A comprehensive list of notable seamless pipe manufacturers in India:

1) Sachiya Steel International Pvt. Ltd.

2) Jindal SAW Ltd.

3) Maharashtra Seamless Ltd.

4) ISMT Ltd.

5) Ratnamani Pipes & Tubes Ltd.