Threaded Couplings Manufacturer In India

Threaded Couplings Manufacturer In India

Threaded couplings are essential components in various piping systems, serving to securely join two lengths of pipe together efficiently and effectively. Sachiya Steel International Private Limited of India’s premier manufacturer of high-quality threaded couplings offers an expansive selection of these fittings that meets the diverse needs of industries worldwide.

Types of Threaded Couplings

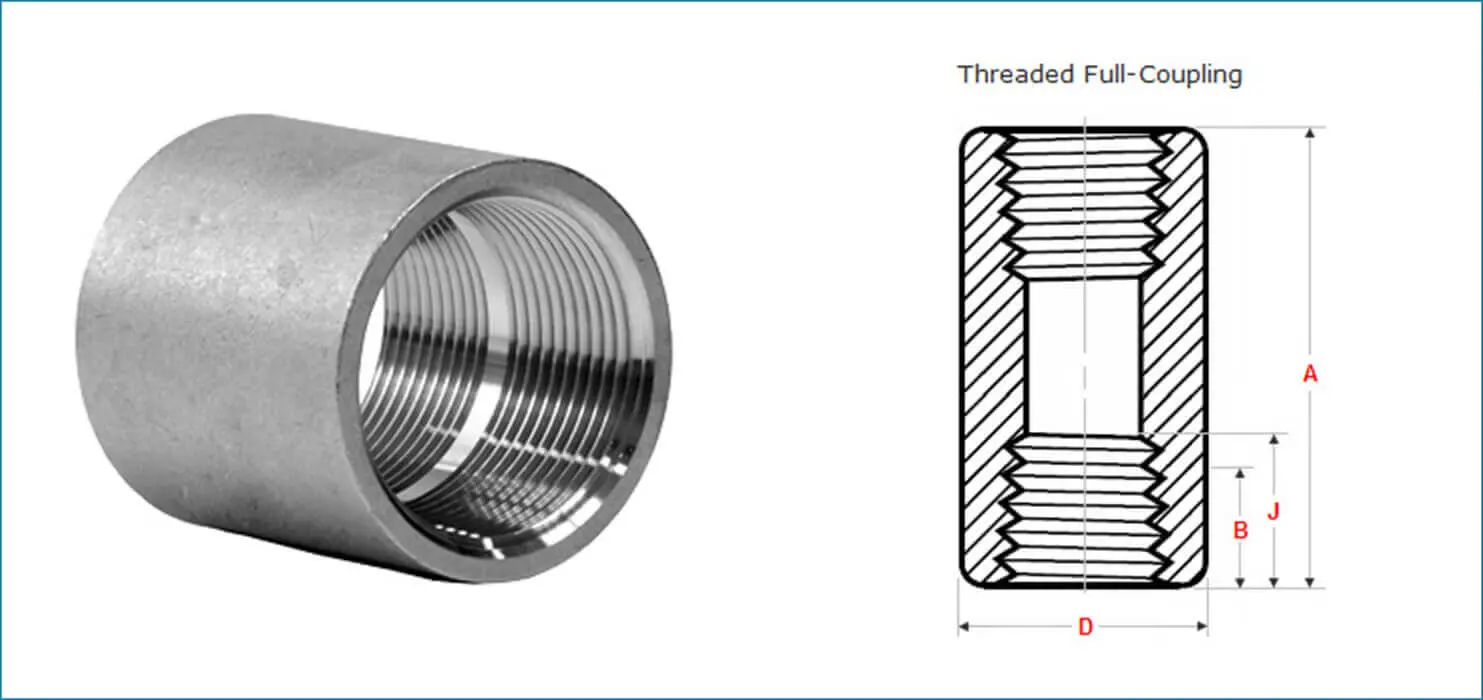

- Threaded Full Coupling: This is a robust fitting used to connect two pipes of the same diameter. It features threads on both ends, making it ideal for applications in high-pressure environments like oil and gas, chemical processing, and power plants.

- Half Threaded Coupling: This type of coupling has threads on only one end, often used when space constraints require a smaller fitting. They are typically used in scenarios where a pipe needs to be joined to a fitting or another pipe with a different diameter.

- Threaded Quick Connect Coupling: These couplings allow for quick and easy connection and disconnection of pipes without the need for tools. They are particularly useful in fluid transfer systems where frequent connections are necessary.

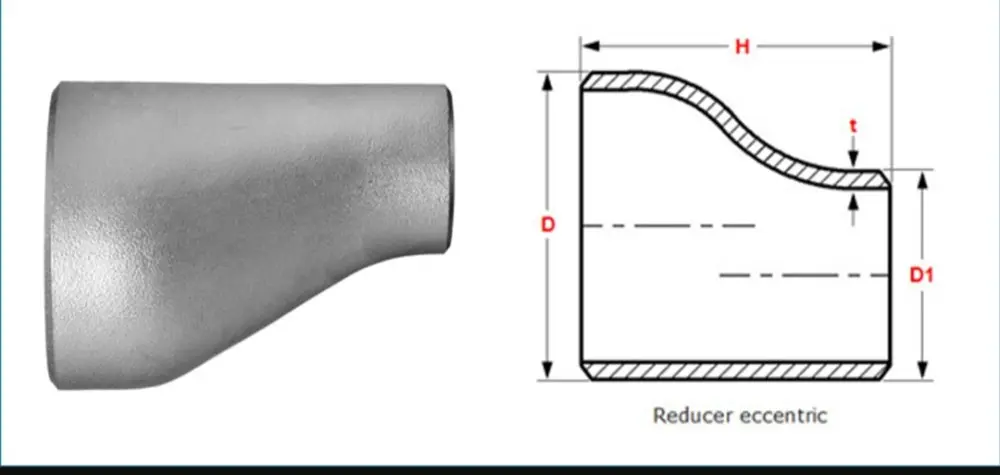

- Reducing Coupling: This coupling is used to connect pipes of different diameters. It’s essential for systems where the pipe size changes, ensuring a secure and leak-proof connection.

- Threaded Coupling Nuts and Shaft Couplers: These are used in mechanical systems to connect shafts or secure components in place. Available in various thread sizes, they ensure precise alignment and stability.

Materials and Standards

Our threaded couplings are manufactured using a variety of materials, including:

- Stainless Steel: Ideal for corrosive environments, our stainless steel couplings meet ASTM A182 standards, offering durability and resistance to harsh chemicals.

- Carbon Steel: These couplings, compliant with ASTM/ASME A105, are suitable for high-pressure applications and offer excellent strength.

- Alloy Steel: For applications requiring high-temperature resistance, our alloy steel couplings, meeting ASTM A182 specifications, are the perfect choice.

- Nickel Alloys and Copper-Nickel: For specialized applications, such as marine or chemical processing, our nickel alloy couplings offer superior corrosion resistance.

Applications

Threaded couplings are widely used across multiple industries, including:

- Oil and Gas: Ensuring secure connections in pipelines, especially in high-pressure and high-temperature environments.

- Chemical Processing: Resistant to corrosive chemicals, these couplings are crucial in maintaining the integrity of pipelines in chemical plants.

- Water Supply Systems: Used extensively in both municipal and industrial water supply networks to ensure leak-proof connections.

- HVAC Systems: Essential in heating, ventilation, and air conditioning systems to prevent leaks and maintain system integrity.

- Fire Protection Systems: Ensuring reliable connections in fire sprinkler systems, where secure and leak-proof fittings are critical.

Why Choose Sachiya Steel International?

- High-Quality Materials: Our products are made from the finest materials, ensuring long-lasting performance even in the most demanding environments.

- Compliance with International Standards: All our threaded couplings meet global standards such as ASME B16.11, ensuring compatibility and reliability.

- Customization: We offer tailored solutions to meet the specific needs of our clients, ensuring that each coupling fits perfectly within its application.

- Global Reach: Our products are trusted by industries around the world, with a strong export network that ensures timely delivery to various global markets.

Threaded couplings are an essential part of any robust piping system. Whether you’re working in the oil and gas industry, chemical processing, or general plumbing, Sachiya Steel International Private Limited offers the perfect solution with our range of high-quality threaded couplings. Contact us today to find out how we can meet your piping needs with our superior products and customer-focused service.