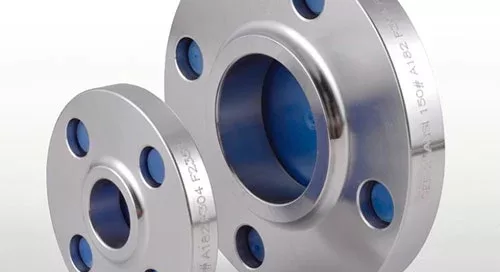

Flange Manufacturer In India

Flange Manufacturer In India

Regarding finding a reliable and reputable Flange manufacturer in India, Sachiya Steel International stands out as a leading player. With an unwavering commitment to quality, precision, and customer satisfaction, Sachiya Steel International has emerged as a trusted name for superior stainless steel (SS) flanges. As a one-stop destination for all your flange requirements, they offer an extensive range of products that cater to diverse industrial needs. In this article, we will explore the expertise, experience, and exceptional services Sachiya Steel International provides in the realm of flange manufacturing.

Flange Manufacturer in India: Sachiya Steel International

Sachiya Steel International, a renowned flange manufacturer in India, specializes in producing high-quality stainless steel flanges. With an emphasis on precision engineering and adherence to international standards, Sachiya Steel International has earned a formidable reputation in the industry.

Flanges Specifications

| Size Range | 1/2 NPS to 40 NPS (15 NB to 1000 NB) |

|---|---|

| Class | 150#, 300#, 400#, 600#, 900#, 1500#, 2500#, PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100 |

| Grades | F-304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316Ti, 316N, 316LN, 310, 317, 317L, 321, 321H, 347, 347H, 904L

F-51, 53, 55, 60, 68 |

| Specifications | ASTM, ASME, DIN EN |

| Type | SO, WN, SW, BL, THRD, Lap Joint, Orifice Type, Reducing Flanges, Spectacle Blind |

| Face | RF, FF, RTJ, T&G |

| Applications |

|

Expertise in SS Flange Manufacturing

Sachiya Steel International possesses extensive expertise in manufacturing stainless steel flanges, enabling them to deliver products of unmatched quality. Their team of skilled professionals combines years of experience with advanced production techniques to create flanges that meet the most stringent requirements.

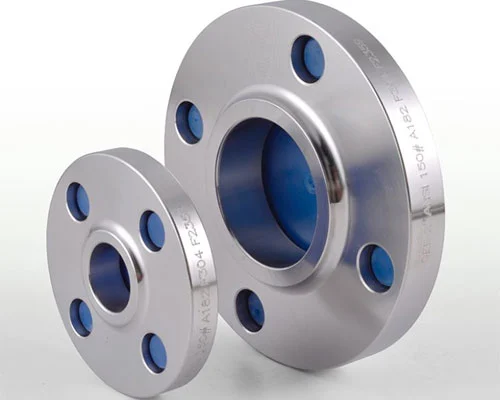

Comprehensive Range of SS Flanges

Sachiya Steel International offers a comprehensive range of stainless steel flanges for diverse industry applications. Their product catalog includes:

- Weld Neck Flanges: These flanges provide a secure connection and are widely used in high-pressure applications.

- Slip-On Flanges: Ideal for low-pressure systems, slip-on flanges are easy to install and cost-effective.

- Blind Flanges: Designed to seal the end of a pipe, blind flanges are commonly used in piping systems with no requirement for regular inspection.

- Socket Weld Flanges: Known for their durability and easy installation, socket weld flanges are commonly used in small-bore piping systems.

- Lap Joint Flanges: These flanges are used with stub ends for easy dismantling and alignment of bolt holes.

- Threaded Flanges: Threaded flanges are used in low-pressure applications and can be easily assembled without welding.

- Orifice Flanges: These flanges are specifically designed for orifice plate assemblies used in flow measurement systems.

- Spectacle Blind Flanges: Spectacle blind flanges combine a blind flange and a spacer ring, commonly used in pipeline maintenance.

Quality Assurance and Certifications

Sachiya Steel International is committed to delivering flanges that meet the highest quality standards. Their manufacturing processes are certified and comply with globally recognized certifications such as ISO 9001:2015. This ensures that customers receive products that are not only reliable but also conform to industry benchmarks.

Customization and Tailored Solutions

Understanding that each customer’s requirements may vary, Sachiya Steel International offers customized flange solutions. They can fulfill individual needs and provide tailor-made solutions, from specific dimensions and materials to unique designs. This level of customization sets them apart from other flange manufacturers in India.

FAQs (Frequently Asked Questions)

Sachiya Steel International offers many advantages, including expertise in SS flange manufacturing, a comprehensive product range, adherence to quality standards, and the ability to provide customized solutions. Sachiya Steel International primarily uses stainless steel alloys such as SS 304, SS 316, SS 321, and SS 347 for manufacturing their flanges. These materials offer excellent corrosion resistance and durability. Yes, Sachiya Steel International specializes in providing flanges with non-standard dimensions. They can accommodate specific size requirements as per the customer’s specifications. Yes, Sachiya Steel International’s flanges comply with international standards such as ASTM, ASME, ANSI, and DIN, ensuring that customers receive products of exceptional quality. Sachiya Steel International follows a rigorous quality assurance process, including material testing, dimensional inspections, and documentation control. They have certifications such as ISO 9001:2015 to validate their commitment to quality. Yes, Sachiya Steel International provides reliable packaging and shipping services to ensure the safe delivery of their flanges to customers worldwide. They use appropriate packaging materials to protect the products during transit.What are the advantages of choosing Sachiya Steel International as a flange manufacturer in India?

What materials are used in the production of SS flanges?

Can Sachiya Steel International provide flanges in non-standard dimensions?

Are Sachiya Steel International’s flanges compliant with industry standards?

How does Sachiya Steel International ensure product quality?

Does Sachiya Steel International offer packaging and shipping services?

Conclusion

Sachiya Steel International, a prominent flange manufacturer in India, has established itself as a trusted provider of high-quality stainless steel flanges. Their expertise, comprehensive range of products, commitment to quality, and ability to offer customized solutions make them a preferred choice for global industries. Whether you require flanges for high-pressure systems, low-pressure applications, or unique dimensions, Sachiya Steel International can meet your needs with precision and excellence.