Monel Alloy 400 Socket Weld Fittings Manufacturers In India

Monel Alloy 400 Socket Weld Fittings Manufacturers In India

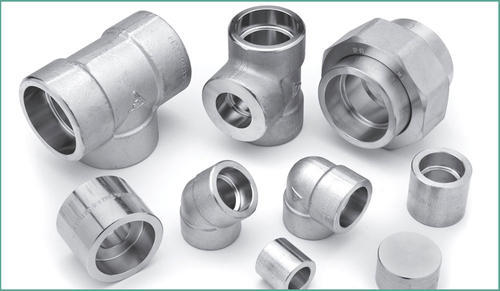

Sachiya Steel International is one of the Leading Manufacturer And Exporter of High Quality quality Monel Alloy 400 Socket Weld Fittings, which is not sensitive towards heating and welding. The chemical composition of these Monel 400 Forged Socket Weld Elbow has been designed to give it outstanding corrosion resistance in as wide a range of media as possible, both oxidizing and reducing. Our Monel 400 Forged Socket Weld Tee is often used in equipment handling reducing chemical environments; and chemical process industry involving hydrochloric, sulphuric, phosphoric, and acetic acids.

These Monel 400 Forged Socket Weld Cap has poor corrosion resistance to oxidizing environments, which may form when iron or copper is present in a system containing hydrochloric acid. Our Monel 400 Forged Socket Weld Coupling is not recommended for use in oxidizing media or in the presence of ferric or cupric salts, for the reason that they may cause rapid premature corrosion failure.

Premature failure may occur if these Monel 400 Forged Socket Weld Cross used where iron or copper is present in a system containing hydrochloric acid. Our Monel 400 Forged Socket Weld Union are meant to bring the cost down and increase the strength of the product high. These Monel 400 Forged Socket Weld Plug is non harden able by heat treatment, which provides resistance to pure sulphuric acid and a number of non – oxidizing acids.

Monel Alloy 400 Socket Weld Fittings Specifications |

||

| Specifications | : | ASTM B564 & ASME B564 |

| Size | : | 1/8” NB to 4” NB |

| Standards |

: | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Class | : | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | : | Socket weld Fittings |

Monel 400 Forged Socket weld Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cu | Mo | Ni | Fe |

| Monel 400 | 0.30 max | 2 max | 0.50 max | – | 0.024 max | 28 – 34 | – | 63.00 min | 2.50 max |

Monel Alloy 400 Socket weld Fitting Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.8 g/cm3 | 1350 °C (2550 °F) | Psi – 80000 , MPa – 550 | Psi – 35000 , MPa – 240 | 40 % |

Equivalent Grades for 400 Monel Forged Socket weld Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

Monel 400 Forged Socket weld Fittings Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Monel 400 Forged Socket weld Fittings Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc.

Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and Macro Test

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)