Everything You Need to Know About Schedule 80 Pipe

Everything You Need to Know About Schedule 80 Pipe

What Is Schedule 80 Pipe?

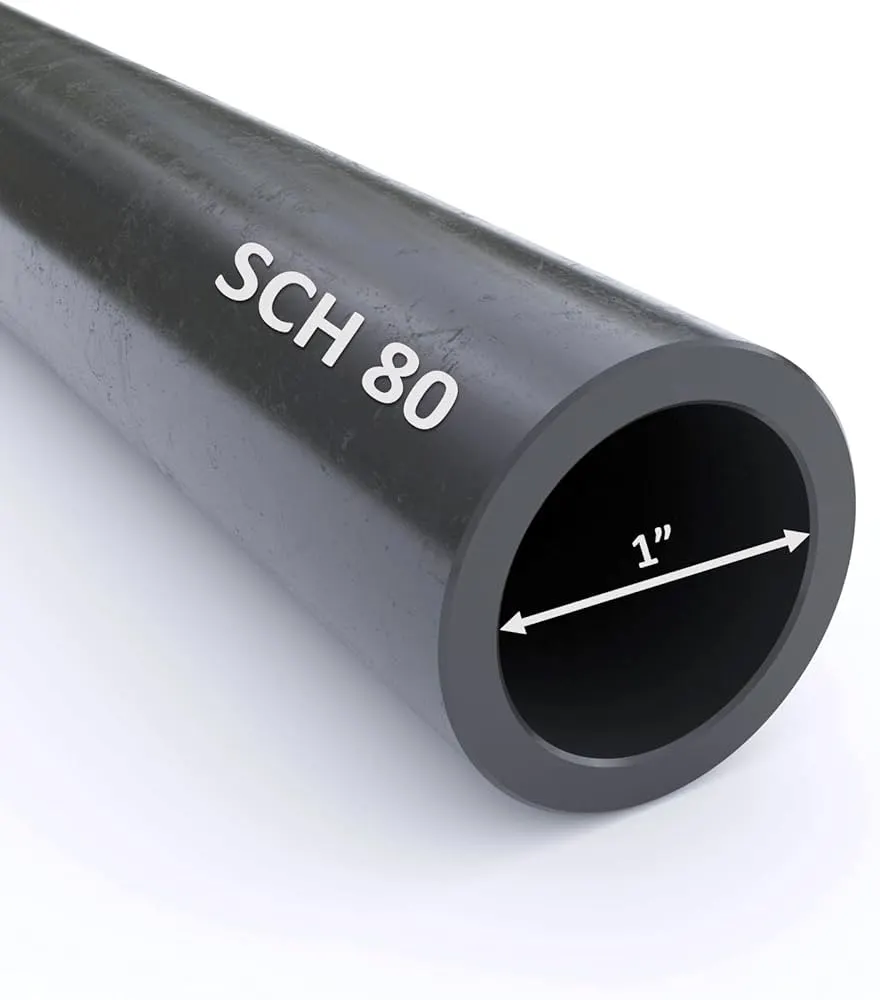

Schedule 80 pipe, frequently labeled as sch 80 or sch80, refers to a standardized pipe category defined under the ASME (American Society of Mechanical Engineers) B36.10 guidelines. This classification highlights pipe wall thickness relative to its nominal diameter. Schedule 80 pipes feature thicker walls compared to lighter schedules like Schedule 40, making them suited for high-pressure, high-temperature, and critical industrial applications.

Key Features of Schedule 80 Pipes:

- Thicker Walls – Designed to endure higher levels of pressure.

- Enhanced Strength – Suitable for demanding environments.

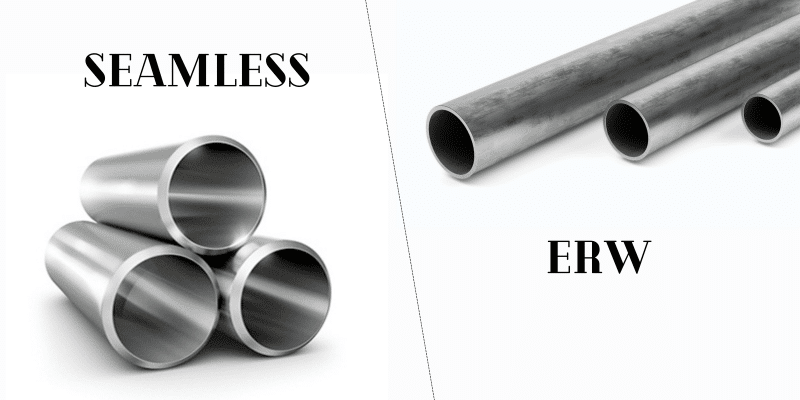

- Wide Compatibility – Available in materials like carbon steel, stainless steel, and alloy steel.

The schedule 80 pipe thickness in mm depends on the pipe’s diameter, with larger pipes typically having greater wall thickness to maintain strength and safety standards.

Benefits of Schedule 80 Pipes

1. Exceptional Pressure Resistance

The wall thickness of Schedule 80 pipes gives them impressive pressure ratings, making them suitable for fluid and gas transport under high pressure in critical systems.

2. Temperature Handling

Sch 80 pipes are designed for high-temperature environments, allowing use in systems like steam pipelines or hot liquid transport.

3. Corrosion Resistance

When constructed from materials such as stainless steel or with coatings such as galvanization, sch 80 pipes can withstand chemical corrosion in aggressive environments like chemical plants or wastewater systems.

4. Versatility in Applications

Their robust construction makes schedule 80 pipes the first choice for:

- Chemical transport pipelines

- Structural support systems

- High-pressure hydraulic systems

- Industrial water supply

- Oil and gas pipelines

5. Installation Flexibility

Schedule 80 pipes are highly versatile. They support various methods of installation, such as welding, threading, or flange-fitting, matching diverse system needs.

Schedule 80 Pipe Dimensions and Thickness

The table below presents the schedule 80 pipe thickness in mm for common sizes. This variation ensures that the pipes can withstand specific pressure requirements.

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 1/8″ | 10.3 mm | 1.73 mm | 0.37 kg/m |

| 1/4″ | 13.7 mm | 2.24 mm | 0.84 kg/m |

| 1/2″ | 21.3 mm | 2.77 mm | 1.27 kg/m |

| 3/4″ | 26.7 mm | 2.87 mm | 1.69 kg/m |

| 1″ | 33.4 mm | 3.38 mm | 2.50 kg/m |

| 1 1/2″ | 48.3 mm | 3.68 mm | 4.05 kg/m |

| 2″ | 60.3 mm | 3.91 mm | 5.44 kg/m |

| 6″ | 168.3 mm | 7.11 mm | 28.26 kg/m |

| 12″ | 323.8 mm | 10.31 mm | 79.73 kg/m |

This consistent formatting makes it easy for engineers and system planners to determine pipe sizes based on system needs.

Pressure Ratings of Schedule 80 Pipes

Schedule 80 steel pipes are designed for high-pressure environments. Their pressure ratings vary based on material and size. Below is a quick reference table showcasing approximate pressure capacities for typical sizes in PSI (pounds per square inch):

| Nominal Size (NPS) | Outer Diameter (OD) | Pressure Rating (PSI) |

|---|---|---|

| 1″ | 33.4 mm | 6670 PSI |

| 2″ | 60.3 mm | 4498 PSI |

| 4″ | 114.3 mm | 3670 PSI |

| 6″ | 168.3 mm | 3195 PSI |

| 8″ | 219.1 mm | 2841 PSI |

These numbers demonstrate the capacity of sch 80 pipes to handle high-pressure requirements, making them integral to industrial installations.

Factors That Impact Pressure Ratings:

- Material Used – Stainless steel generally has higher resistance compared to carbon steel.

- Diameter and Thickness – Larger diameters with thicker walls improve rating capacity.

- Temperature Conditions – Heat impacts pipe durability under pressure.

Material Characteristics of Schedule 80 Pipes

Schedule 80 pipes are manufactured in a range of materials, each selected based on specific application needs.

| Material | Common Use Case | Advantages |

|---|---|---|

| Carbon Steel | High-pressure piping for systems like oil and gas. | Durable, cost-efficient, and strong. |

| Stainless Steel | Chemical transport, wastewater systems, and food-grade piping. | Non-corrosive with high longevity. |

| Alloy Steel | Power plants and petrochemical applications. | High heat and pressure tolerance. |

| PVC (Plastic) | Lightweight, low-pressure pipelines like plumbing systems. | Cost-effective, easy to handle. |

Selecting the right material ensures both performance and cost-efficiency for the project at hand.

Applications of Schedule 80 Pipes

The robust features of schedule 80 pipes make them ideal for various industrial and commercial uses. Key sectors include:

1. Industrial Plants

Schedule 80 steel pipes are frequently used in manufacturing units for transporting chemicals, oils, and gases due to their strength and tolerance for chemical corrosion.

2. Construction and Structural Support

Because of their high tensile strength, sch 80 pipes are used in architecture and construction to support building frameworks.

3. Water Treatment Systems

These pipes resist high pressure and temperature, which is essential in water purification and desalination plants.

4. HVAC Systems

Heating, ventilation, and air conditioning systems require pipes that can handle temperature fluctuations over long periods, making schedule 80 pipes a go-to choice.

Choosing the Right Schedule 80 Pipe

To select the optimal sch 80 pipe for your application, consider the following factors:

-

System Requirements

Evaluate the pressure, temperature, and environmental conditions your pipe will encounter. -

Material Selection

Identify whether you need carbon steel, stainless steel, or specialized alloys based on industry needs. -

Accurate Sizing

Refer to dimension tables to ensure the pipe fits seamlessly into your system. -

Protective Coatings

For chemical exposure or outdoor use, ensure the pipes are appropriately coated to prevent wear or corrosion.

Summary of Schedule 80 Pipes

| Feature | Details |

|---|---|

| Thickness | Thicker walls ensure superior pressure handling. |

| Dimensions | Supports diameters ranging from 1/8″ to 32″. |

| Common Materials | Includes carbon steel, stainless steel, and alloys. |

| Key Applications | Industrial, chemical, oil & gas, HVAC systems. |

| Pressure Tolerance | PSI ratings significantly higher than Schedule 40. |

Investing in schedule 80 pipes provides durability, reliability, and performance, regardless of the system’s operational intensity.

Take the Next Step

Looking for the best schedule 80 pipe solutions for your project? Ensure you source pipes from trusted suppliers, ensuring compliance with all industry safety and performance standards. Verify dimensions, thickness, and pressure capabilities to meet all your operational needs today!

For durable and reliable piping solutions, trust Sachiya Steel International Private Limited. Contact us today for more information or a customized quote.

Transform your operations with Schedule 80 pipes engineered for excellence!

At Sachiya Steel International Private Limited, we’re not just offering pipes; we’re providing solutions you can trust, delivered with unmatched precision and commitment to quality.