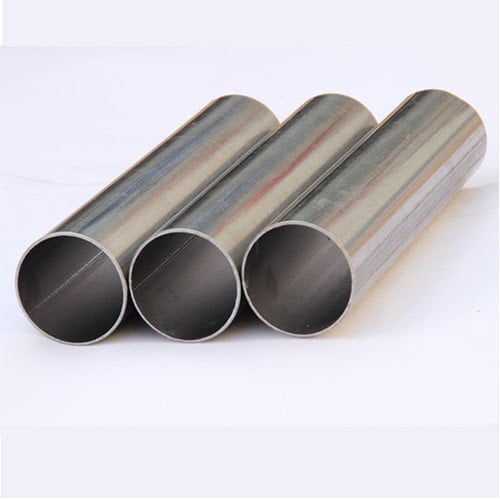

ASTM B729 Seamless Tube Manufacturer

Sachiya Steel International is a well-known firm in trading and exporting ASTM B729 Seamless Tube, which has better resistance to sea water then Grade 316. Our ASTM B729 Nickel Pipes gives better guaranteed corrosion resistance. These ASME SB 729 Nickel Tubes is not generally suitable for use at temperatures above 300 Degree C, where the CPT is generally at least 35 Degree C.

Our ASTM B729 Nickel Alloy Pipes neither suffers from precipitation of brittle micro constituents, nor below -50 Degree C because of its ductile – to – brittle – transition. These ASME SB 729 Nickel Alloy Tubes has excellent general corrosion resistance and superior in most environments.

ASTM B729 Seamless Tube Manufacture

Our ASTM B729 Nickel Alloy Seamless Pipes has excellent resistance to localized corrosion including inter – granular, pitting and crevice corrosion. Sachiya Steel International is one of the well-known suppliers and dealer of these ASME SB 729 Nickel Alloy Seamless Tubes, where the standard composition has over the years been refined by us and resulting the restricted composition range.

Our ASTM B729 Nickel Alloy Cold-Worked Pipes is also resistant to chloride stress corrosion cracking (SCC) at temperatures of up to about 150 Degree C. These ASME SB 729 Nickel Alloy Cold-Worked Tubes will often perform well in environments which cause premature failure of austenitic grades. Care should be taken when cold forming these ASTM B729 Nickel Alloy Hot Finished Pipes, where it is further not optimized for cold forming or cold heading operations.

ASTM B729 Seamless Pipes and Tubes Specifications |

||

| Size | : | 6.00 mm OD up to 914.4 mm OD |

| Thickness | : | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS |

| Length | : | Within 13500mm |

| Type | : | Seamless Pipes, Seamless Tubes |

| Grades | : | UNS N08020, UNS N08024, UNS N08026 |

ASTM B729 Seamless Pipes & Tubes Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

ASTM B729 Pipe and Tube Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc.

Alloy Steel T91 Seamless Tube may be furnished bare or coated and with capped ends. tubes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of Alloy Steel T91 Seamless Tubes may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.

Alloy Steel T91 Seamless Tube may be furnished bare or coated and with capped ends. tubes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of Alloy Steel T91 Seamless Tubes may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.