Alloy Steel Grade 9 Sheets Manufacturers In India

Alloy Steel Grade 9 Sheets Manufacturers In India

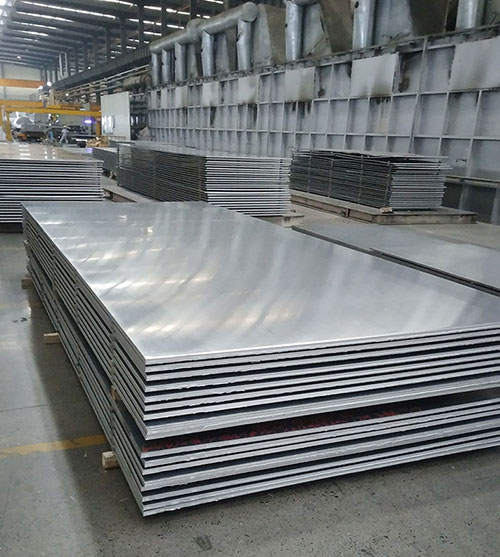

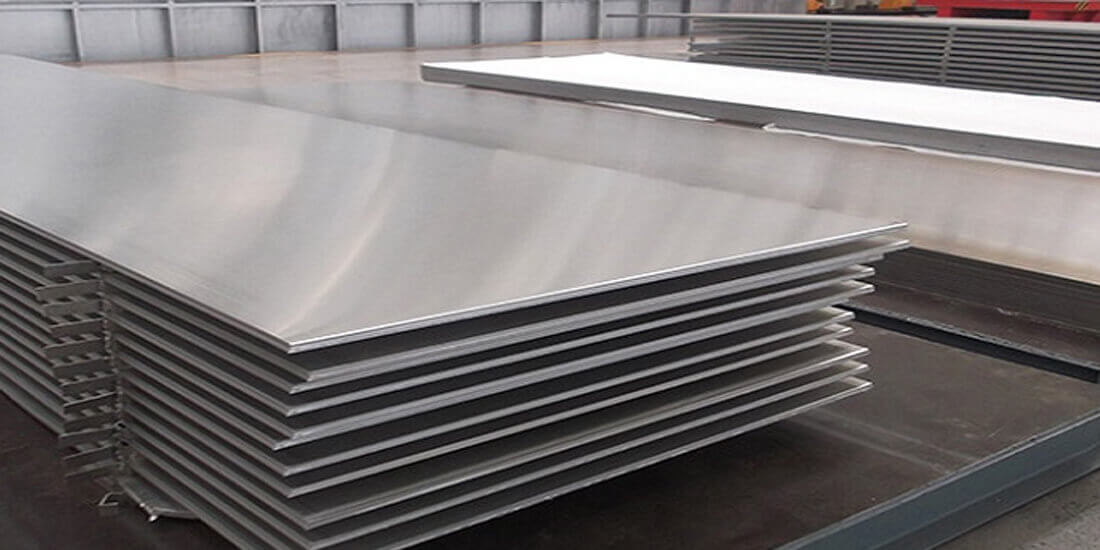

Sachiya Steel International Is One Of The Leading Manufacturer And Exporter Of High Quality Alloy Steel Grade 9 Sheets, Plates, Coils, which is a pressure vessel grade steel which is used commonly by fabricators who supply the oil and gas industry. We are a quality provider of our Alloy Steel Grade 9 Plates which is widely used establish connection of pipes and deliver maximum level of stability in the functionality of these vital structures. Our company is widely appreciated in offering these Alloy Steel Grade 9 Coils to the clients, which is made by using quality material and sophisticate technology of the market.

Our respected clients can purchase these Alloy Steel Grade 9 Slating Coils from us in a confine time frame on several specifications. By leveraging our rich technical knowledge in the domain of trading and supplying, we are involved in offering the best quality of these Alloy Steel Grade 9 Perforated Coils, which are in perfect dimension, tough design and reliable in nature, moreover is widely available in diverse sizes and specifications as per the clients’ requisite.

We offer various types of surface finishes, hot dip tinning, electroplating, profiled strips, deburred edges, mirror surface for our Alloy Steel Gr. 9 Plates. In tunes with advanced tools and machinery, we are presenting a wide range of these Alloy Steel Gr. 9 Coils to our dear clients, which are processed according to the international quality standards.

Alloy Steel Gr 9 Sheet, Plate & Coil Specifications |

||

| Specifications | : | ASTM A387 / ASME SA387 |

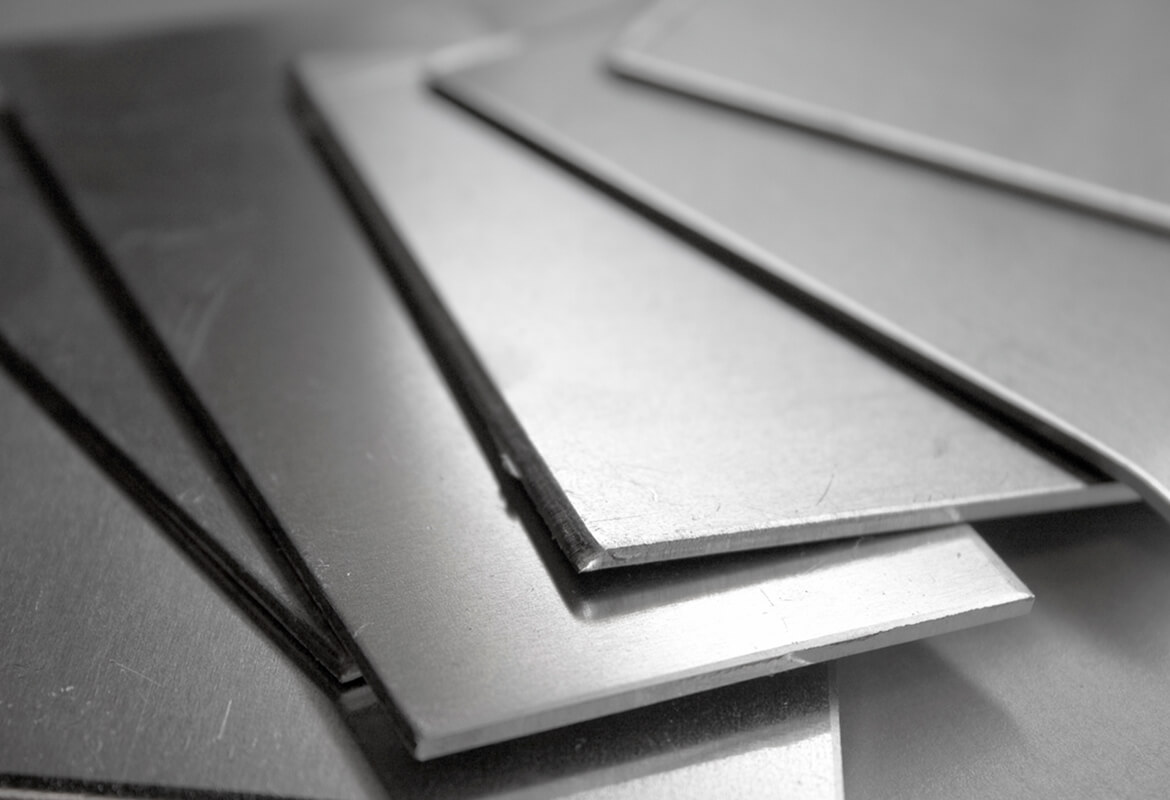

| Thickness | : | 1mm-300mm |

| Width |

: | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, 4050mm etc |

| Length | : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm, 15000mm etc |

| Surface | : | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR) |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip etc. |

Alloy Steel Gr 9 Plate, Sheet & Coil Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| Alloy Steel Gr 9 | 0.15 max | 0.30-0.60 | 1.0 max | 0.030 max | 0.030 max | 8.0 – 10.0 | 0.90 – 1.10 | – | – |

Alloy Steel Gr 9 Sheets, Plates & Coils Tensile Requirements

| Tensile (MPa) | Yield (MPa) | Elongation (50mm) | Elongation (200mm) | Reduction of Area |

| 415 – 585 | 205 min | 18% min | – | 40% min |

Alloy Steel Gr 9 Sheets, Plate & Coils Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Alloy Steel Gr 9 Sheets, Plate & Coils Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and Macro Test

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)