Weld Neck Flange Manufacturers In India

Sachiya Steel International is One Of The Leading Manufacturer, Supplier and Exporter of high Quality Weld Neck Flanges. Weld Neck Flanges are usually used in high pressure systems and are suitable for cold or hot temperatures. Also, we can produce as per your drawings and specifications. An ANSI class is a designation kept by a set of specifications or standards, that is meant to convey both the pressure as well as temperature ratings of pipe flanges. In its denotation, the word Class is mentioned after a by dimensionless number. This includes Class 150, 300, 400, Weld Neck Flange Class 600, 900, 1500, and 2500.

Flanges are structural systems used to connect pipes, tubes, valves in a piping system. A Weld Neck Flange is made up of a long tapered hub or bore. These flanges possess superior strength and enhanced hardness. They are widely used in high as well as low pressure and temperature applications. The long tapered hub of the Wnrf Flange gives the pipes structural support during rigorous and extreme movement of pipes within the system. Apart from this, flanges also help in low cycle fatigue, which is caused due to extension of the line. The Stainless Steel Weld Neck Flange is highly resistant to all forms of corrosion and oxidation mediums. These flanges possess superior tensile and yield strength. They can be easily machined or elongated. We are the top Weld neck flanges manufacturers in India. Our institution aims to produce the best products, which are available for all at reasonable prices.

A Carbon Steel Weld Neck Flange is designed with a higher concentration of carbon. Due to the presence of excess carbon, these flanges possess enhanced strength and ductility. They also have a low melting point. In the Weld Neck Pipe Flanges, the flange provides a leakproof sealing to the piping system. The inside diameter of these flanges is bored to match the mating of the pipe. This allows for low turbulence and a smooth flow of fluids or gases. A Raised Face Weld Neck Flange has a raised surface above the welding area, which is designed to reduce the surface area on the seal. This helps put pressure on the flange joint to create a strong joint. In the Flat Face Weld Neck Flange, the top surface is machined down to make it completely flat. These flanges are not affected by the bending pressure, which breaks or destroys some flanges when they are bolted or torqued. A Reducing Weld Neck Flange is mostly used in piping systems where there is a requirement to join pipes of different sizes together. These flanges can also be employed to reduce the diameter of the pipe. The Long Weld Neck Flange is a preferred choice in volatile and hostile environments. These flanges are widely used in petroleum, oil, gas, and chemical processing refineries. We are amongst the few Long Weld Neck Flange manufacturers who make use of the best raw materials and latest technology to manufacture all our products.

The Rtj Weld Neck Flange is used in systems where a metal-to-metal seal is required. These high-integrity sealing flanges can withstand high pressures and temperatures above 700-800 degrees. A Weld Neck Orifice Flange is installed in pipelines to check the flow rate of either fluids or gases in a pipeline. All our products can be easily customized in different chemical make-up, shapes, and sizes as per the requirements of our clients. If you have any queries or want to know more about our Welding Neck Flange, contact us for more information.

Sachiya Steel International Is One of The Leading Manufacturer And Exporter Of High Quality Carbon Steel Weld Neck Flange in RF FF Rtj Face, check SS Long Weld Neck Flange dimensions in mm and pressure class

Weld Neck Flanges Specifications

| Weld Neck Flanges Standards |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ASME B16.5 Weld Neck Flanges Size Chart |

1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Weld Neck Flanges Pressure Calculation in DIN |

6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Weld Neck Flanges |

| Weld Neck Flanges Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Weld Neck Flanges |

| UNI |

6Bar 10Bar 16Bar 25Bar 40Bar Weld Neck Flanges |

| JIS |

5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Weld Neck Flanges |

| Coating |

Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Weld Neck Flanges |

| EN |

6Bar 10Bar 16Bar 25Bar 40Bar Weld Neck Flanges |

| Test Certificates |

EN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etc |

| Most common types of Weld Neck Flanges |

Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type |

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Production technique |

- Forged, Heat treated and machined

|

| Test |

Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, Ultrasonic flaw detector, Magnetic particle detector |

| Special design |

As per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2″) to 200 NB (8″)

Equal and Reducing Configurations |

| Origin |

Indian / West Europe / Japan / USA / Korean |

| Equipment |

Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Weld Neck Flanges Uses & application |

- Bitumen upgraders.

- Heavy oil refineries.

- Nuclear power (mostly seamless).

- Petrochemicals and acids.

|

| Manufacturer of |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

Weld Neck Flanges: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

- B.S: BS4504 , BS3293, BS1560, BS10

- AS 2129: Table D; Table E; Table H

- ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

- ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

- American standard (ANSI)

- German (DIN)

- British standard (BS)

- DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 Weld Neck Flanges

- The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

|

| Export to |

Saudi Arabia, Peru, Egypt, Indonesia, Brazil, Spain, USA, Canada, Ukraine, Singapore, Thailand, Oman, Ireland, Korea, Iran, India, Dubai |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 |

WELD NECK FLANGES MATERIAL & GRADES :

Stainless Steel Weld Neck Flanges : ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Carbon Steel Weld Neck Flanges : ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70

Alloy Steel Weld Neck Flanges : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Weld Neck Flanges : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Super Duplex Weld Neck Flanges : ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61

Nickel Alloy Weld Neck Flanges : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy Weld Neck Flanges : UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu-Ni-70/30)

Low Temperature Carbon Steel Weld Neck Flanges : ASTM A350, LF2, LF3

Weld Neck Flanges Price List

|

Weld Neck Flange type

|

Weld Neck Flange Price in India

|

Weld Neck Flange Price in USD

|

Weld Neck Flange Price in UAE Dirham

|

|

Stainless Steel Weld Neck Flange

|

INR 1540.61 / Kg

|

USD $ 10.45 /Kg

|

AED 72.46 UAE Dirham

|

|

Carbon steel Weld neck flanges

|

INR 5270.01 / Kg

|

USD $ 65.89 /Kg

|

AED 258.76 UAE Dirham

|

|

Alloy steel Weld neck flanges

|

INR 4544.14 / Kg

|

USD $ 55.36 /Kg

|

AED 230.08 UAE Dirham

|

|

ANSI b16 5 Weld neck flanges

|

INR 5255.01 / Kg

|

USD $ 65.56 /Kg

|

AED 220.08 UAE Dirham

|

|

ASME b16.47 Weld neck flanges

|

INR 6649.87 / Kg

|

USD $ 75.56 /Kg

|

AED 341.01 UAE Dirham

|

Stainless Steel Weld Neck Flange Dimension chart

| Welding Neck Flange Bores |

Nominal Pipe Size

(inches) |

Outside Diameter

(inches) |

Inside Diameter (inches) |

| Light Wall 1) |

Schedule 20 |

Schedule 30 |

Standard Wall |

Schedule 40 |

Schedule 60 |

| 1/2 |

0.840 |

0.674 |

– |

– |

0.622 |

0.622 |

– |

| 3/4 |

1.050 |

0.884 |

– |

– |

0.824 |

0.824 |

– |

| 1 |

1.315 |

1.097 |

– |

– |

1.049 |

1.049 |

– |

| 1 1/4 |

1.660 |

1.442 |

– |

– |

1.380 |

1.380 |

– |

| 1 1/2 |

1.900 |

1.682 |

– |

– |

1.610 |

1.610 |

– |

| 2 |

2.375 |

2.157 |

– |

– |

2.067 |

2.067 |

– |

| 2 1/2 |

2.875 |

2.635 |

– |

– |

2.469 |

2.469 |

– |

| 3 |

3.500 |

3.260 |

– |

– |

3.068 |

3.068 |

– |

| 3 1/2 |

4.000 |

3.760 |

– |

– |

3.548 |

3.548 |

– |

| 4 |

4.500 |

4.260 |

– |

– |

4.026 |

4.026 |

– |

| 5 |

5.563 |

5.295 |

– |

– |

5.047 |

5.047 |

– |

| 6 |

6.625 |

6.357 |

– |

– |

6.065 |

6.065 |

– |

| 8 |

8.625 |

8.329 |

8.125 |

8.071 |

7.981 |

7.981 |

7.813 |

| 10 |

10.750 |

10.420 |

10.250 |

10.136 |

10.020 |

10.020 |

9.750 |

| 12 |

12.750 |

12.390 |

12.250 |

12.090 |

12.000 |

11.938 |

11.626 |

| 14 |

14.000 |

13.500 |

13.376 |

13.250 |

13.250 |

13.124 |

12.812 |

| 16 |

16.000 |

15.500 |

15.376 |

15.250 |

15.250 |

15.000 |

14.688 |

| 18 |

18.000 |

17.500 |

17.376 |

17.124 |

17.250 |

16.876 |

16.500 |

| 20 |

20.000 |

19.500 |

19.250 |

19.000 |

19.250 |

18.812 |

18.376 |

| 24 |

24.000 |

23.500 |

23.250 |

22.876 |

23.250 |

22.624 |

22.062 |

| 30 |

30.000 |

29.376 |

29.000 |

28.750 |

29.250 |

– |

– |

| 36 |

36.000 |

35.376 |

35.000 |

34.750 |

35.250 |

34.500 |

– |

| 42 |

42.000 |

– |

– |

– |

41.250 |

– |

– |

| 48 |

48.000 |

– |

– |

– |

47.250 |

– |

– |

Exporter & supplier of Mild/ Alloy Steel Reducing Weld Neck Flange in Grade ASTM A182 F11, ask for a free sample now

| Welding Neck Flange Bores |

Nominal Pipe Size

(inches) |

Outside Diameter

(inches) |

Inside Diameter (inches) |

| Extra Strong |

Schedule 80 |

Schedule 100 |

Schedule 120 |

Schedule 140 |

Schedule 160 |

Double Extra Strong |

| 1/2 |

0.840 |

0.546 |

0.546 |

– |

– |

– |

0.464 |

0.252 |

| 3/4 |

1.050 |

0.742 |

0.742 |

– |

– |

– |

0.612 |

0.434 |

| 1 |

1.315 |

0.957 |

0.957 |

– |

– |

– |

0.815 |

0.599 |

| 1 1/4 |

1.660 |

1.278 |

1.278 |

– |

– |

– |

1.160 |

0.896 |

| 1 1/2 |

1.900 |

1.500 |

1.500 |

– |

– |

– |

1.338 |

1.100 |

| 2 |

2.375 |

1.939 |

1.939 |

– |

– |

– |

1.687 |

1.503 |

| 2 1/2 |

2.875 |

2.323 |

2.323 |

– |

– |

– |

2.125 |

1.771 |

| 3 |

3.500 |

2.900 |

2.900 |

– |

– |

– |

2.624 |

2.300 |

| 3 1/2 |

4.000 |

3.364 |

3.364 |

– |

– |

– |

– |

2.728 |

| 4 |

4.500 |

3.826 |

3.826 |

– |

3.624 |

– |

3.438 |

3.152 |

| 5 |

5.563 |

4.813 |

4.813 |

– |

4.563 |

– |

4.313 |

4.063 |

| 6 |

6.625 |

5.761 |

5.761 |

– |

5.501 |

– |

5.187 |

4.897 |

| 8 |

8.625 |

7.625 |

7.625 |

7.437 |

7.187 |

7.001 |

6.813 |

6.875 |

| 10 |

10.750 |

9.750 |

9.562 |

9.312 |

9.062 |

8.750 |

8.500 |

8.750 |

| 12 |

12.750 |

11.750 |

11.374 |

11.062 |

10.750 |

10.500 |

10.126 |

10.750 |

| 14 |

14.000 |

13.000 |

12.500 |

12.124 |

11.814 |

11.500 |

11.188 |

– |

| 16 |

16.000 |

15.000 |

14.312 |

13.938 |

13.564 |

13.124 |

12.812 |

– |

| 18 |

18.000 |

17.000 |

16.124 |

15.688 |

15.250 |

14.876 |

14.438 |

– |

| 20 |

20.000 |

19.000 |

17.938 |

17.438 |

17.000 |

16.500 |

16.062 |

– |

| 24 |

24.000 |

23.000 |

21.562 |

20.938 |

20.376 |

19.876 |

19.312 |

– |

| 30 |

30.000 |

29.000 |

– |

– |

– |

– |

– |

– |

| 36 |

36.000 |

35.000 |

– |

– |

– |

– |

– |

– |

| 42 |

42.000 |

41.000 |

– |

– |

– |

– |

– |

– |

| 48 |

48.000 |

47.000 |

– |

– |

– |

– |

– |

– |

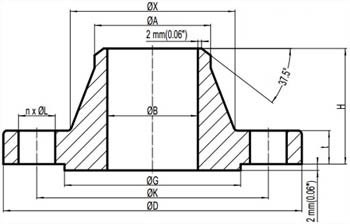

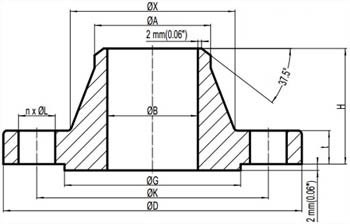

Weld Neck Flanges Dimensions/ Weld Neck Flange Size Chart

ANSI B16.5 Long Weld Neck Flange Dimensions, PN16 Weld Neck Flange Dimensions, 4 Weld Neck flange Dimensions

Weld Neck Flanges Dimensions

ANSI/ASME/ASA B16.5 150lb/sq.in. Flange WN-RF

|

ø

|

D

|

b

|

g

|

m

|

a

|

J*

|

h

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

88,9

|

11,1

|

34,9

|

30,2

|

21,3

|

15,7

|

47,6

|

60,3

|

4

|

15,9

|

0,500

|

|

3/4″

|

98,4

|

12,7

|

42,9

|

38,1

|

26,7

|

20,8

|

52,4

|

69,8

|

4

|

15,9

|

0,700

|

|

1″

|

107,9

|

14,3

|

50,8

|

49,2

|

33,5

|

26,7

|

55,6

|

79,4

|

4

|

15,9

|

1,100

|

|

1 1/4″

|

117,5

|

15,9

|

63,5

|

58,8

|

42,2

|

35,1

|

57,1

|

88,9

|

4

|

15,9

|

1,500

|

|

1 1/2″

|

127,0

|

17,5

|

73,0

|

65,1

|

48,3

|

40,9

|

61,9

|

98,4

|

4

|

15,9

|

1,800

|

|

2″

|

152,4

|

19,0

|

92,1

|

77,8

|

60,3

|

52,6

|

63,5

|

120,6

|

4

|

19,0

|

2,700

|

|

2 1/2″

|

177,8

|

22,2

|

104,8

|

90,5

|

73,1

|

62,7

|

69,8

|

139,7

|

4

|

19,0

|

4,400

|

|

3″

|

190,5

|

23,8

|

127,0

|

107,9

|

88,9

|

78,0

|

69,8

|

152,4

|

4

|

19,0

|

5,200

|

|

3 1/2″

|

215,9

|

23,8

|

139,7

|

122,2

|

101,6

|

90,2

|

71,4

|

177,8

|

8

|

19,0

|

6,400

|

|

4″

|

228,6

|

23,8

|

157,2

|

134,9

|

114,3

|

102,4

|

76,2

|

190,5

|

8

|

19,0

|

7,500

|

|

5″

|

254,0

|

23,8

|

185,7

|

163,5

|

141,2

|

128,3

|

88,9

|

215,9

|

8

|

22,2

|

9,200

|

|

6″

|

279,4

|

25,4

|

215,9

|

192,1

|

168,4

|

154,2

|

88,9

|

241,3

|

8

|

22,2

|

11,000

|

|

8″

|

342,9

|

28,6

|

269,9

|

246,1

|

219,1

|

202,7

|

101,6

|

298,4

|

8

|

22,2

|

18,300

|

|

10″

|

406,4

|

30,2

|

323,8

|

304,8

|

273,0

|

254,5

|

101,6

|

361,9

|

12

|

25,4

|

25,000

|

|

12″

|

482,6

|

31,7

|

381,0

|

365,1

|

323,8

|

304,8

|

114,3

|

431,8

|

12

|

25,4

|

39,000

|

|

14″

|

533,4

|

34,9

|

412,7

|

400,0

|

355,6

|

336,5

|

127,0

|

476,2

|

12

|

28,6

|

51,000

|

|

16″

|

596,9

|

36,5

|

469,9

|

457,2

|

406,4

|

387,3

|

127,0

|

539,7

|

16

|

28,6

|

60,000

|

|

18″

|

635,0

|

39,7

|

533,4

|

504,8

|

457,2

|

438,1

|

139,7

|

577,8

|

16

|

31,7

|

71,000

|

|

20″

|

698,5

|

42,9

|

584,2

|

558,8

|

508,0

|

488,9

|

144,5

|

635,0

|

20

|

31,7

|

88,000

|

|

22″

|

749,3

|

46,0

|

641,2

|

609,6

|

558,8

|

539,7

|

149,2

|

692,1

|

20

|

34,9

|

102,000

|

|

24″

|

812,8

|

47,6

|

692,1

|

663,6

|

609,6

|

590,5

|

152,4

|

749,3

|

20

|

34,9

|

119,000

|

|

*

|

The data “J” corresponds to the STD schedule

|

|

ANSI/ASME/ASA B16.5 300lb/sq.in. Flange WN-RF

|

|

ø

|

D

|

b

|

g

|

m

|

a

|

J*

|

h

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

95,2

|

14,3

|

34,9

|

38,1

|

21,3

|

15,7

|

52,4

|

66,7

|

4

|

15,9

|

0,900

|

|

3/4″

|

117,5

|

15,9

|

42,9

|

47,6

|

26,7

|

20,8

|

57,1

|

82,5

|

4

|

19,0

|

1,500

|

|

1″

|

123,8

|

17,5

|

50,8

|

54,0

|

33,5

|

26,7

|

61,9

|

88,9

|

4

|

19,0

|

1,900

|

|

1 1/4″

|

133,3

|

19,0

|

63,5

|

63,5

|

42,2

|

35,1

|

65,1

|

98,4

|

4

|

19,0

|

2,600

|

|

1 1/2″

|

155,6

|

20,6

|

73,0

|

69,8

|

48,3

|

40,9

|

68,3

|

114,3

|

4

|

22,2

|

3,300

|

|

2″

|

165,1

|

22,2

|

92,1

|

84,1

|

60,3

|

52,6

|

69,8

|

127,0

|

8

|

19,0

|

3,600

|

|

2 1/2″

|

190,5

|

25,4

|

104,8

|

100,0

|

73,1

|

62,7

|

76,2

|

149,2

|

8

|

22,2

|

5,400

|

|

3″

|

209,5

|

28,6

|

127,0

|

117,5

|

88,9

|

78,0

|

79,4

|

168,3

|

8

|

22,2

|

7,400

|

|

3 1/2″

|

228,6

|

30,2

|

139,7

|

133,3

|

101,6

|

90,2

|

81,0

|

184,1

|

8

|

22,2

|

8,900

|

|

4″

|

254,0

|

31,7

|

157,2

|

146,0

|

114,3

|

102,4

|

85,7

|

200,0

|

8

|

22,2

|

11,900

|

|

5″

|

279,4

|

34,9

|

185,7

|

177,8

|

141,2

|

128,3

|

98,4

|

234,9

|

8

|

22,2

|

16,000

|

|

6″

|

317,5

|

36,5

|

215,9

|

206,4

|

168,4

|

154,2

|

98,4

|

269,9

|

12

|

22,2

|

20,200

|

|

8″

|

381,0

|

41,3

|

269,9

|

260,3

|

219,1

|

202,7

|

111,1

|

330,2

|

12

|

25,4

|

31,000

|

|

10″

|

444,5

|

47,6

|

323,4

|

320,7

|

273,0

|

254,5

|

117,5

|

387,3

|

16

|

28,6

|

44,300

|

|

12″

|

520,7

|

50,8

|

381,0

|

374,6

|

323,8

|

304,8

|

130,2

|

450,8

|

16

|

31,7

|

64,000

|

|

14″

|

584,2

|

54,0

|

412,7

|

425,4

|

355,6

|

336,5

|

142,9

|

514,3

|

20

|

31,7

|

88,000

|

|

16″

|

647,7

|

57,1

|

469,9

|

482,6

|

406,4

|

387,3

|

146,0

|

571,5

|

20

|

34,9

|

113,000

|

|

18″

|

711,2

|

60,3

|

533,4

|

533,4

|

457,2

|

438,1

|

158,7

|

628,6

|

24

|

34,9

|

134,000

|

|

20″

|

774,7

|

63,5

|

584,2

|

587,4

|

508,0

|

488,9

|

161,9

|

685,8

|

24

|

34,9

|

171,000

|

|

22″

|

838,2

|

66,7

|

641,2

|

641,2

|

558,8

|

539,7

|

165,1

|

742,9

|

24

|

41,3

|

195,000

|

|

24″

|

914,4

|

69,8

|

692,1

|

701,7

|

609,6

|

590,5

|

168,3

|

812,8

|

24

|

41,3

|

238,000

|

|

*

|

The data “J” corresponds to the STD schedule

|

Weld Neck Flange Dimensions Class 900

|

| Size in Inch |

Size in mm |

Outer Diameter |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

Bore |

RF Diameter |

RF Height |

PCD |

Weld Face |

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

| 1/2 |

15 |

120 |

22.3 |

38 |

21.3 |

60 |

Refer Note |

34.9 |

7 |

82.6 |

1.6 |

| 3/4 |

20 |

130 |

25.4 |

44 |

26.7 |

70 |

42.9 |

7 |

88.9 |

1.6 |

| 1 |

25 |

150 |

28.6 |

52 |

33.4 |

73 |

50.8 |

7 |

101.6 |

1.6 |

| 1 1/4 |

32 |

160 |

28.6 |

64 |

42.2 |

73 |

63.5 |

7 |

111.1 |

1.6 |

| 1 1/2 |

40 |

180 |

31.8 |

70 |

48.3 |

83 |

73 |

7 |

123.8 |

1.6 |

| 2 |

50 |

215 |

38.1 |

105 |

60.3 |

102 |

92.1 |

7 |

165.1 |

1.6 |

| 2 1/2 |

65 |

245 |

41.3 |

124 |

73 |

105 |

104.8 |

7 |

190.5 |

1.6 |

| 3 |

80 |

240 |

38.1 |

127 |

88.9 |

102 |

127 |

7 |

190.5 |

1.6 |

| 4 |

100 |

290 |

44.5 |

159 |

114.3 |

114 |

157.2 |

7 |

235 |

1.6 |

| 5 |

125 |

350 |

50.8 |

190 |

141.3 |

127 |

185.7 |

7 |

279.4 |

1.6 |

| 6 |

150 |

380 |

55.6 |

235 |

168.3 |

140 |

215.9 |

7 |

317.5 |

1.6 |

| 8 |

200 |

470 |

63.5 |

298 |

219.1 |

162 |

269.9 |

7 |

393.7 |

1.6 |

| 10 |

250 |

545 |

69.9 |

368 |

273 |

184 |

323.8 |

7 |

469.9 |

1.6 |

| 12 |

300 |

610 |

79.4 |

419 |

323.8 |

200 |

381 |

7 |

533.4 |

1.6 |

| 14 |

350 |

640 |

85.8 |

451 |

355.6 |

213 |

412.8 |

7 |

558.8 |

1.6 |

| 16 |

400 |

705 |

88.9 |

508 |

406.4 |

216 |

469.9 |

7 |

616 |

1.6 |

| 18 |

450 |

785 |

101.6 |

565 |

457 |

229 |

533.4 |

7 |

685.8 |

1.6 |

| 20 |

500 |

855 |

108 |

622 |

508 |

248 |

584.2 |

7 |

749.3 |

1.6 |

| 24 |

600 |

1040 |

139.7 |

749 |

610 |

292 |

692.2 |

7 |

901.7 |

1.6 |

Class 1500 Weld Neck Flange Dimensions

|

| Size in Inch |

Size in mm |

Outer Diameter |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

Bore |

RF Diameter |

RF Height |

PCD |

Weld Face |

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

| 1/2 |

15 |

120 |

22.3 |

38 |

21.3 |

60 |

Refer Note |

34.9 |

7 |

82.6 |

1.6 |

| 3/4 |

20 |

130 |

25.4 |

44 |

26.7 |

70 |

42.9 |

7 |

88.9 |

1.6 |

| 1 |

25 |

150 |

28.6 |

52 |

33.4 |

73 |

50.8 |

7 |

101.6 |

1.6 |

| 1 1/4 |

32 |

160 |

28.6 |

64 |

42.2 |

73 |

63.5 |

7 |

111.1 |

1.6 |

| 1 1/2 |

40 |

180 |

31.8 |

70 |

48.3 |

83 |

73 |

7 |

123.8 |

1.6 |

| 2 |

50 |

215 |

38.1 |

105 |

60.3 |

102 |

92.1 |

7 |

165.1 |

1.6 |

| 2 1/2 |

65 |

245 |

41.3 |

124 |

73 |

105 |

104.8 |

7 |

190.5 |

1.6 |

| 3 |

80 |

265 |

47.7 |

133 |

88.9 |

117 |

127 |

7 |

203.2 |

1.6 |

| 4 |

100 |

310 |

54 |

162 |

114.3 |

124 |

157.2 |

7 |

241.3 |

1.6 |

| 5 |

125 |

375 |

73.1 |

197 |

141.3 |

156 |

185.7 |

7 |

292.1 |

1.6 |

| 6 |

150 |

395 |

82.6 |

229 |

168.3 |

171 |

215.9 |

7 |

317.5 |

1.6 |

| 8 |

200 |

485 |

92.1 |

292 |

219.1 |

213 |

269.9 |

7 |

393.7 |

1.6 |

| 10 |

250 |

585 |

108 |

368 |

273 |

254 |

323.8 |

7 |

482.6 |

1.6 |

| 12 |

300 |

675 |

123.9 |

451 |

323.8 |

283 |

381 |

7 |

571.5 |

1.6 |

| 14 |

350 |

750 |

133.4 |

495 |

355.6 |

298 |

412.8 |

7 |

635 |

1.6 |

| 16 |

400 |

825 |

146.1 |

552 |

406.4 |

311 |

469.9 |

7 |

704.8 |

1.6 |

| 18 |

450 |

915 |

162 |

597 |

457 |

327 |

533.4 |

7 |

774.7 |

1.6 |

| 20 |

500 |

985 |

177.8 |

641 |

508 |

356 |

584.2 |

7 |

831.8 |

1.6 |

| 24 |

600 |

1170 |

203.2 |

762 |

610 |

406 |

692.2 |

7 |

990.6 |

1.6 |

Note: Welding Neck bore is derived from the pipe schedule

|

Class 2500 Weld Neck Flange Dimensions

|

| Size in Inch |

Size in mm |

Outer Diameter |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

Bore |

RF Diameter |

RF Height |

PCD |

Weld Face |

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

| 1/2 |

15 |

135 |

30.2 |

43 |

21.3 |

73 |

Refer Note |

34.9 |

7 |

88.9 |

1.6 |

| 3/4 |

20 |

140 |

31.8 |

51 |

26.7 |

79 |

42.9 |

7 |

95.2 |

1.6 |

| 1 |

25 |

160 |

35 |

57 |

33.4 |

89 |

50.8 |

7 |

108 |

1.6 |

| 1 1/4 |

32 |

185 |

38.1 |

73 |

42.2 |

95 |

63.5 |

7 |

130.2 |

1.6 |

| 1 1/2 |

40 |

205 |

44.5 |

79 |

48.3 |

111 |

73 |

7 |

146 |

1.6 |

| 2 |

50 |

235 |

50.9 |

95 |

60.3 |

127 |

92.1 |

7 |

171.4 |

1.6 |

| 2 1/2 |

65 |

265 |

57.2 |

114 |

73 |

143 |

104.8 |

7 |

196.8 |

1.6 |

| 3 |

80 |

305 |

66.7 |

133 |

88.9 |

168 |

127 |

7 |

228.6 |

1.6 |

| 4 |

100 |

355 |

76.2 |

165 |

114.3 |

190 |

157.2 |

7 |

273 |

1.6 |

| 5 |

125 |

420 |

92.1 |

203 |

141.3 |

229 |

185.7 |

7 |

323.8 |

1.6 |

| 6 |

150 |

485 |

108 |

235 |

168.3 |

273 |

215.9 |

7 |

368.3 |

1.6 |

| 8 |

200 |

550 |

127 |

305 |

219.1 |

318 |

269.9 |

7 |

438.2 |

1.6 |

| 10 |

250 |

675 |

165.1 |

375 |

273 |

419 |

323.8 |

7 |

539.8 |

1.6 |

| 12 |

300 |

760 |

184.2 |

441 |

323.8 |

464 |

381 |

7 |

619.1 |

1.6 |

Note: Welding Neck bore is derived from the pipe schedule

JIS Weld Neck Flange Dimensions

JIS 16K Weld Neck Flange Dimensions, JIS 20K Weld Neck Flange Dimensions

| Nominal |

Outside |

Inside |

Outside |

Sectional Dimensions of Flange |

Bolt Hole |

Nominal |

Approx. |

| Dia. of |

Dia. of |

Dia. of |

Dia. of |

t |

T |

Dia. of Hub |

r |

Dia. of |

Dia. of |

Bolt. |

Number |

Hole |

Bolt |

Weight |

| Flange |

Steel |

Flange |

Flange |

a |

b |

Face |

Raised Face |

Circle |

of Bolt |

Dia. |

Size |

(kg) |

| |

Pipe |

do |

D |

f |

g |

Dia |

Holes |

h |

|

BL |

SOH |

| 10 |

17.3 |

17.8 |

90 |

12 |

16 |

26 |

28 |

4 |

1 |

46 |

65 |

4 |

15 |

M12 |

0.53 |

0.52 |

| 15 |

21.7 |

22.2 |

95 |

12 |

16 |

30 |

32 |

4 |

1 |

51 |

70 |

4 |

15 |

M12 |

0.6 |

0.58 |

| 20 |

27.2 |

27.7 |

100 |

14 |

20 |

38 |

42 |

4 |

1 |

56 |

75 |

4 |

15 |

M12 |

0.79 |

0.75 |

| 25 |

34 |

34.5 |

125 |

14 |

20 |

46 |

50 |

4 |

1 |

67 |

90 |

4 |

19 |

M16 |

1.22 |

1.16 |

| 32 |

42.7 |

43.2 |

135 |

16 |

22 |

56 |

60 |

5 |

2 |

76 |

100 |

4 |

19 |

M16 |

1.66 |

1.53 |

| 40 |

48.6 |

49.1 |

140 |

16 |

24 |

62 |

66 |

5 |

2 |

81 |

105 |

4 |

19 |

M16 |

1.79 |

1.64 |

| 50 |

60.5 |

61.1 |

155 |

16 |

24 |

76 |

80 |

5 |

2 |

96 |

120 |

8 |

19 |

M16 |

2.09 |

1.83 |

| 65 |

76.3 |

77.1 |

175 |

18 |

26 |

94 |

98 |

5 |

2 |

116 |

140 |

8 |

19 |

M16 |

3.08 |

2.58 |

| 80 |

89.1 |

90 |

200 |

20 |

28 |

108 |

112 |

6 |

2 |

132 |

160 |

8 |

23 |

M20 |

4.41 |

3.61 |

| -90 |

101.6 |

102.6 |

210 |

20 |

30 |

120 |

124 |

6 |

2 |

145 |

170 |

8 |

23 |

M20 |

4.92 |

3.89 |

| 100 |

114.3 |

115.4 |

225 |

22 |

34 |

134 |

138 |

6 |

2 |

160 |

185 |

8 |

23 |

M20 |

6.29 |

4.87 |

| 125 |

139.8 |

141.2 |

270 |

22 |

34 |

164 |

170 |

6 |

2 |

195 |

225 |

8 |

25 |

M22 |

9.21 |

7.09 |

| 150 |

165.2 |

166.6 |

305 |

24 |

38 |

196 |

202 |

6 |

2 |

230 |

260 |

12 |

25 |

M22 |

12.7 |

9.57 |

| 200 |

216.3 |

218 |

350 |

26 |

40 |

244 |

252 |

6 |

2 |

275 |

305 |

12 |

25 |

M22 |

18.4 |

12 |

| 250 |

267.4 |

269.5 |

430 |

28 |

44 |

304 |

312 |

6 |

2 |

345 |

380 |

12 |

27 |

M24 |

30.4 |

20.1 |

| 300 |

318.5 |

321 |

480 |

30 |

48 |

354 |

364 |

8 |

3 |

395 |

430 |

16 |

27 |

M24 |

40.5 |

24.3 |

| 350 |

355.6 |

358.1 |

540 |

34 |

52 |

398 |

408 |

8 |

3 |

440 |

480 |

16 |

33 |

M30×3 |

57.5 |

34.4 |

| 400 |

406.4 |

409 |

605 |

38 |

60 |

446 |

456 |

10 |

3 |

495 |

540 |

16 |

33 |

M30×3 |

81.7 |

47.4 |

| 450 |

457.2 |

460 |

675 |

40 |

64 |

504 |

514 |

10 |

3 |

560 |

605 |

20 |

33 |

M30×3 |

107 |

61.8 |

| 500 |

508 |

511 |

730 |

42 |

68 |

558 |

568 |

10 |

3 |

615 |

660 |

20 |

33 |

M30×3 |

132 |

73.7 |

| -550 |

558.8 |

562 |

795 |

44 |

70 |

612 |

622 |

10 |

3 |

670 |

720 |

20 |

39 |

M36×3 |

163 |

87.9 |

| 600 |

609.6 |

613 |

845 |

46 |

74 |

666 |

676 |

10 |

3 |

720 |

770 |

24 |

39 |

M36×3 |

192 |

98.4 |

| 650 |

660.4 |

664 |

895 |

48 |

77 |

704 |

726 |

10 |

5 |

770 |

820 |

24 |

39 |

M36×3 |

– |

– |

| 700 |

711.2 |

715 |

960 |

50 |

80 |

754 |

776 |

10 |

5 |

820 |

875 |

24 |

42 |

M39×3 |

– |

– |

| 750 |

762 |

766 |

1020 |

52 |

83 |

806 |

832 |

10 |

5 |

880 |

935 |

24 |

42 |

M39×3 |

– |

– |

| 800 |

812.8 |

817 |

1085 |

54 |

86 |

865 |

885 |

10 |

5 |

930 |

990 |

24 |

48 |

M45×3 |

– |

– |

| 850 |

863.6 |

868 |

1135 |

56 |

89 |

916 |

936 |

10 |

5 |

980 |

1040 |

24 |

48 |

M45×3 |

– |

– |

| 900 |

914.4 |

919 |

1185 |

58 |

93 |

968 |

986 |

10 |

5 |

1030 |

1090 |

28 |

48 |

M45×3 |

– |

– |

| 1000 |

1016 |

1021 |

1320 |

62 |

99 |

1070 |

1098 |

12 |

5 |

1140 |

1210 |

28 |

56 |

M52×3 |

– |

– |

| 1100 |

1117.6 |

1123 |

1420 |

66 |

105 |

1180 |

1200 |

12 |

15 |

1240 |

1310 |

32 |

56 |

M52×3 |

– |

– |

| 1200 |

1219.2 |

1225 |

1530 |

70 |

112 |

1282 |

1302 |

12 |

5 |

1350 |

1420 |

32 |

56 |

M52×3 |

– |

– |

| 1300 |

1320.8 |

1326 |

1645 |

74 |

– |

– |

– |

– |

5 |

1450 |

1530 |

32 |

62 |

M56×3 |

– |

– |

| 1350 |

1371.6 |

1377 |

1700 |

76 |

– |

– |

– |

– |

5 |

1510 |

1590 |

32 |

62 |

M56×3 |

– |

– |

| 1400 |

1422.4 |

1428 |

1755 |

78 |

– |

– |

– |

– |

5 |

1560 |

1640 |

36 |

62 |

M56×3 |

– |

– |

| 1500 |

1524 |

1529 |

1865 |

80 |

– |

– |

– |

– |

5 |

1670 |

1750 |

36 |

62 |

M56×3 |

– |

– |

ANSI B16.5 Weld Neck Flange Schedule Chart, Weld Neck Flange Thickness Chart

WELDING NECK FLANGES BORES (in inches)

|

Nom

Pipe

Size |

Outside

Diam |

Sched

10 |

Sched

20 |

Sched

30 |

Std.

Wall |

Sched

40 |

Sched

60 |

Extra

Strong |

Sched

80 |

Sched

100 |

Sched

120 |

Sched

140 |

Sched

160 |

Double

Extra

Strong |

| 1/2” |

0.840 |

0.674 |

– |

– |

0.622 |

0.622 |

– |

0.546 |

0.546 |

– |

– |

– |

0.464 |

0.252 |

| 3/4” |

1.050 |

0.884 |

– |

– |

0.824 |

0.824 |

– |

0.742 |

0.742 |

– |

– |

– |

0.612 |

0.434 |

| 1” |

1.315 |

1.097 |

– |

– |

1.049 |

1.049 |

– |

0.957 |

0.957 |

– |

– |

– |

0.815 |

0.599 |

| 1.1/4” |

1.660 |

1.442 |

– |

– |

1.380 |

1.380 |

– |

1.278 |

1.278 |

– |

– |

– |

1.160 |

0.896 |

| 1.1/2” |

1.900 |

1.682 |

– |

– |

1.610 |

1.610 |

– |

1.500 |

1.500 |

– |

– |

– |

1.338 |

1.100 |

| 2” |

2.375 |

2.157 |

– |

– |

2.067 |

2.067 |

– |

1.939 |

1.939 |

– |

– |

– |

1.687 |

1.503 |

| 2.1/2” |

2.875 |

2.635 |

– |

– |

2.469 |

2.469 |

– |

2.323 |

2.323 |

– |

– |

– |

2.125 |

1.771 |

| 3” |

3.500 |

3.260 |

– |

– |

3.068 |

3.068 |

– |

2.900 |

2.900 |

– |

– |

– |

2.624 |

2.300 |

| 3-1/2” |

4.000 |

3.760 |

– |

– |

3.548 |

3.548 |

– |

3.364 |

3.364 |

– |

– |

– |

– |

2.728 |

| 4” |

4.500 |

4.260 |

– |

– |

4.026 |

4.026 |

– |

3.826 |

3.826 |

– |

3.624 |

– |

3.438 |

3.152 |

| 5” |

5.563 |

5.295 |

– |

– |

5.047 |

5.047 |

– |

4.813 |

4.813 |

– |

4.563 |

– |

4.313 |

4.063 |

| 6” |

6.625 |

6.357 |

– |

– |

6.065 |

6.065 |

– |

5.761 |

5.761 |

– |

5.501 |

– |

5.187 |

4.897 |

| 8” |

8.625 |

8.329 |

8.125 |

8.071 |

7.981 |

7.981 |

7.813 |

7.625 |

7.625 |

7.437 |

7.187 |

7.001 |

6.813 |

6.875 |

| 10” |

10.750 |

10.420 |

10.250 |

10.136 |

10.020 |

10.020 |

9.750 |

9.750 |

9.562 |

9.312 |

9.062 |

8.750 |

8.500 |

8.750 |

| 12” |

12.750 |

12.390 |

12.250 |

12.090 |

12.000 |

11.938 |

11.626 |

11.750 |

11.374 |

11.062 |

10.750 |

10.500 |

10.126 |

10.750 |

| 14” |

14.000 |

13.500 |

13.376 |

13.250 |

13.250 |

13.124 |

12.812 |

13.000 |

12.500 |

12.124 |

11.814 |

11.500 |

11.188 |

– |

| 16” |

16.000 |

15.500 |

15.376 |

15.250 |

15.250 |

15.000 |

14.688 |

15.000 |

14.312 |

13.938 |

13.564 |

13.124 |

12.812 |

– |

| 18” |

18.000 |

17.500 |

17.376 |

17.124 |

17.250 |

16.876 |

16.500 |

17.000 |

16.124 |

15.688 |

15.250 |

14.876 |

14.438 |

– |

| 20” |

20.000 |

19.500 |

19.250 |

19.000 |

19.250 |

18.812 |

18.376 |

19.000 |

17.938 |

17.438 |

17.000 |

16.500 |

16.062 |

– |

| 24” |

24.000 |

23.500 |

23.250 |

22.876 |

23.250 |

22.624 |

22.062 |

23.000 |

21.562 |

20.938 |

20.376 |

19.876 |

19.312 |

– |

| 30” |

30.000 |

29.376 |

29.000 |

28.750 |

29.250 |

– |

– |

29.000 |

– |

– |

– |

– |

– |

– |

| 36” |

36.000 |

35.376 |

35.000 |

34.750 |

35.250 |

34.500 |

– |

35.000 |

– |

– |

– |

– |

– |

– |

| 42” |

42.000 |

– |

– |

– |

41.250 |

– |

– |

41.000 |

– |

– |

– |

– |

– |

– |

Weld Neck Flange Weight Chart, Weld Neck Flange Weight in KG

ANSI B16.5 WELD NECK FLANGES WEIGHT (KGS)

|

Nom

Pipe

Size |

150# |

300# |

600# |

900# |

1500# |

2500# |

|

WN |

S/O |

B/K |

WN |

S/O |

B/K |

WN |

S/O |

B/K |

WN |

S/O |

B/K |

WN |

S/O |

B/K |

WN |

S/O |

B/K |

| 1/2” |

0.7 |

0.4 |

0.5 |

0.8 |

0.7 |

0.8 |

0.9 |

0.8 |

0.8 |

2.1 |

1.8 |

1.9 |

2.1 |

1.8 |

1.9 |

3.2 |

3 |

3 |

| 3/4” |

0.8 |

0.7 |

0.8 |

1.4 |

1.2 |

1.2 |

1.6 |

1.4 |

1.4 |

2.7 |

2.4 |

2.7 |

2.7 |

2.4 |

2.7 |

3.6 |

4 |

4.5 |

| 1” |

1.1 |

0.8 |

0.9 |

1.7 |

1.4 |

1.5 |

1.9 |

1.7 |

1.7 |

3.9 |

3.6 |

3.7 |

3.9 |

3.6 |

3.7 |

5.4 |

5 |

5 |

| 1.1/4” |

1.5 |

1.2 |

1.3 |

2.2 |

1.8 |

2 |

2.6 |

2.1 |

2.4 |

4.5 |

4.1 |

4.3 |

4.5 |

4.1 |

4.3 |

7.8 |

8 |

8 |

| 1.1/2” |

1.8 |

1.4 |

1.6 |

3.2 |

2.7 |

2.9 |

3.6 |

3.1 |

3.4 |

6.2 |

5.4 |

5.9 |

6.2 |

5.4 |

5.9 |

11.5 |

11 |

11 |

| 2” |

2.7 |

2.2 |

2.6 |

3.6 |

3.2 |

3.5 |

4.7 |

3.9 |

4.4 |

11.3 |

10.5 |

11.3 |

11.3 |

10.5 |

11.3 |

19 |

17 |

17 |

| 2.1/2” |

4.4 |

3.5 |

4.1 |

5.4 |

4.5 |

5.3 |

4.8 |

5.4 |

6.8 |

16.3 |

15.8 |

16 |

16.3 |

15.8 |

16 |

24 |

25 |

25 |

| 3” |

5.2 |

3.8 |

5.1 |

7.3 |

5.9 |

7.2 |

8.7 |

7.3 |

8.9 |

15 |

12.3 |

16.8 |

21 |

21.5 |

19.5 |

42.6 |

38 |

39 |

| 3-1/2” |

6.4 |

5 |

6.5 |

8.9 |

7.5 |

9.2 |

11.6 |

9 |

12.7 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

| 4” |

7.5 |

5.6 |

7.5 |

11.8 |

10 |

12.2 |

18.4 |

16.5 |

18.6 |

24 |

23.2 |

24.5 |

31.8 |

31 |

33 |

64 |

58 |

60 |

| 5” |

9.2 |

6.5 |

9.2 |

16 |

12.5 |

16 |

31 |

28.5 |

30.8 |

38.5 |

37.5 |

39.5 |

59 |

58.8 |

60 |

111 |

95 |

101 |

| 6” |

11.0 |

8.1 |

11.8 |

20.2 |

16.5 |

22 |

37 |

36.2 |

38 |

50 |

48.3 |

51.5 |

72 |

74 |

75 |

171 |

146 |

156 |

| 8” |

18.4 |

13 |

20.4 |

31.2 |

25.5 |

36 |

54.5 |

51.5 |

62.2 |

85 |

75 |

89 |

124 |

112 |

125 |

261 |

220 |

242 |

| 10” |

25.5 |

18.4 |

31 |

44.3 |

35 |

55 |

98.5 |

76.2 |

102 |

123 |

110 |

131 |

207 |

184 |

215 |

485 |

420 |

465 |

| 12” |

37 |

28.5 |

47 |

63.5 |

52 |

82.5 |

105 |

89.5 |

132 |

168 |

146 |

187 |

306 |

264 |

316 |

698 |

590 |

665 |

| 14” |

51 |

37.5 |

60 |

86 |

73 |

108 |

150 |

102 |

158 |

198 |

172 |

224 |

416 |

– |

– |

– |

– |

– |

| 16” |

61.5 |

44.5 |

61 |

112 |

88 |

139 |

177 |

150 |

225 |

225 |

192 |

259 |

567 |

– |

– |

– |

– |

– |

| 18” |

71.5 |

54 |

93 |

141 |

115 |

178 |

228 |

180 |

285 |

318 |

272 |

383 |

736 |

– |

– |

– |

– |

– |

| 20” |

85 |

72 |

127 |

173 |

139 |

228 |

285 |

231 |

365 |

376 |

330 |

482 |

929 |

– |

– |

– |

– |

– |

| 24” |

119 |

95 |

190 |

248 |

212 |

350 |

372 |

330 |

532 |

680 |

632 |

905 |

1504 |

– |

– |

– |

– |

– |

Dimensional Tolerances of Weld-Neck Flanges ASME B16.5/ ANSI B16.5 Weld Neck Flange Tolerances

Outside Diameter

≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter

not applicable |

Diameter of Contact Face

1.6 mm Raised Face = ± 0.8 mm

6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub

≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

Diameter of Counterbore

not applicable |

Drilling

Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm

Eccentricity of Bolt Circle with Respect to Facing

≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

Thickness

≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub

≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

ASTM Specification of Weld Neck Flanges

- Alloy Steel High-Temp Weld Neck Flanges

- A182 Gr F1 Weld Neck Flanges

- A182 Gr F11 Weld Neck Flanges

- A182 Gr F12 Weld Neck Flanges

- A182 Gr F22 Weld Neck Flanges

- A182 Gr F5 Weld Neck Flanges

- A182 Gr F9 Weld Neck Flanges

- Alloy Steel Low-Temp Weld Neck Flanges

- A350 Gr LF2 Weld Neck Flanges

- A350 Gr LF3 Weld Neck Flanges

- Austenitic Stainless Steel Weld Neck Flanges

- A182 Gr F304 Weld Neck Flanges

- A182 Gr F316 Weld Neck Flanges

- A182 Gr F321 Weld Neck Flanges

- A182 Gr F347 Weld Neck Flanges

- A182 Gr F304L Weld Neck Flanges

- A182 Gr F316L Weld Neck Flanges

- A182 Gr F317 Weld Neck Flanges

- A182 Gr F317L Weld Neck Flanges

- A182 Gr F321 Weld Neck Flanges

- A182 Gr F310 Weld Neck Flanges

- A182 Gr 347 Weld Neck Flanges

|

- Nickel Alloy Weld Neck Flanges

- ASTM B564 Weld Neck Flanges

- astm b564 uns n06600 Weld Neck Flanges

- astm b564 uns n06625 Weld Neck Flanges

- astm b564 uns no4400 Weld Neck Flanges

- astm b564 uns n08810 Weld Neck Flanges

- astm b564 uns n08811 Weld Neck Flanges

- astm b564 uns n08825 Weld Neck Flanges

- astm b564 uns n04400 Weld Neck Flanges

- astm b564 uns n10276 Weld Neck Flanges

- astm b564 uns n10665 Weld Neck Flanges

- Titanium Weld Neck Flanges

- astm b381 grade f2 Weld Neck Flanges

- astm b381 f5 Weld Neck Flanges

- astm b381 f3 Weld Neck Flanges

- astm b381 f12 Weld Neck Flanges

- astm b381 f7 Weld Neck Flanges

- Other grades: ASTM B381 F1, F2, F2H, F3, F4, F5, F6, F7, F7H, F9, F10, F11, F12, F13, F14, F15, F16, F16H, F17, F18, F19, F20, F21, F23, F24, F25, F26 , F26H, F27, F28, F29, F30, F31, F32, F33, F34, F35, F36, F37, F38 Weld Neck Flanges

- Carbon Steel Weld Neck Flanges

|

Type of Weld Neck Flanges we produce

|

Weld Neck Flanges Class 900

|

Weld Neck Flanges Flat Face

|

|

Weld Neck Flanges Pn16

|

Kf Weld Neck Flanges

|

|

Weld Neck Flanges Class 2500

|

Weld Neck Flanges Slip On

|

|

Weld Neck Flanges Din 2527

|

Weld Neck Flanges Weight 150#

|

|

Weld Neck Flanges Din 2576

|

Weld Neck Flanges With 1/2 Npt

|

|

Weld Neck Flanges Pn 64

|

Weld Neck Flanges Ansi B16.5 150

|

|

Weld Neck Flanges Class 150

|

Weld Neck Flanges Threaded

|

|

Weld Neck Flanges Pn10

|

Weld Neck Flanges B16.47

|

|

Weld Neck Flanges Pn40

|

Weld Neck Flanges Rtj 900

|

|

Weld Neck Flanges Pn 160

|

Weld Neck Flanges Rtj

|

|

Weld Neck Flanges Class 1500

|

Weld Neck Flanges Npt

|

|

Weld Neck Flanges Dn150 Pn16

|

Weld Neck Flanges Jis 5k

|

|

Weld Neck Flanges Class 600

|

Weld Neck Flanges Jis B2220

|

|

Weld Neck Flanges Asme B16.5 Class 300

|

Weld Neck Flanges Ring Type Joint

|

|

Weld Neck Flanges Din 2633

|

Weld Neck Flanges Rtj 1500

|

|

Weld Neck Flanges Class 300

|

Weld Neck Flanges With Threaded Hole

|

|

Weld Neck Flanges Din En 1092-1

|

Weld Neck Flanges Jis 10k

|

Look Price Per KG Of Weld Neck Flange Asme B16.5 Class 150, Class 300 And Class 600 Also Check Sizes Of Weld Neck Flange Din En 1092-1

Weld Neck Flanges Material

| Stainless Steel Weld Neck Flanges |

ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel Weld Neck Flanges |

ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Titanium Weld Neck Flanges |

ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7

ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Alloy Steel Weld Neck Flanges |

ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Copper Nickel Weld Neck Flanges |

ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Copper Weld Neck Flanges |

T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Inconel Weld Neck Flanges |

ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Weld Neck Flanges |

| Brass Weld Neck Flanges |

3602 / 2604 / H59 / H62 / etc. |

| Monel Weld Neck Flanges |

ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Hastelloy Weld Neck Flanges |

ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Aluminium Weld Neck Flanges |

5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Alloy 20 Weld Neck Flanges |

ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Duplex Weld Neck Flanges |

S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Nickel Weld Neck Flanges |

ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Incoloy Weld Neck Flanges |

ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| Super Duplex Weld Neck Flanges |

S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Other Weld Neck Flanges material |

Tin bronze, Aluminum bronze, Lead bronze |

| Nimonic Weld Neck Flanges |

Nimonic 75, Nimonic 80A, Nimonic 90 |

| 254 Smo Weld Neck Flanges |

ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

Weld Neck Flange Types

|

ANSI B16.5 class 150 SWRF Flange Stockholder

|

High Quality SWRF Flanges

|

|

Weld Neck Flange Class 900

|

Weld Neck Flange Welding

|

|

4 Bolt Weld Neck flange

|

ANSI 150 Weld Neck Flange

|

|

Weld Neck Flange Class 2500

|

1 inch Weld Neck Flange

|

|

Flat Face SWRF Flange

|

Weld Neck Flange Class 900

|

|

Weld Neck Flange PN16

|

ASME B16.47 Series A and B SWRF Flanges

|

|

2 inch Weld Neck Flange

|

ANSI B16.5 Class 150 Weld Neck Flanges

|

|

ANSI B16.5 Weld Neck Flanges

|

Weld Neck Flange Dimensions

|

|

ASME B16.5 SWRF Flanges

|

Raised Faced Weld Neck Flanges

|

|

Stainless Steel Weld Neck Flanges Suppliers

|

Weld Neck Tube Flange

|

|

Weld Neck Raised Face Flange

|

300# Weld Neck Flange

|

|

Weld Neck Flange Class 600

|

Weld Neck Pipe Flanges

|

|

Weld Neck RTJ Flange

|

6 inch Weld Neck Flange

|

|

Weld Neck Ring Type Joint Flanges

|

3 inch Weld Neck Flange

|

|

4 inch Weld Neck Flange

|

Weld Neck Flange Class 300

|

Weld Neck Flange Uses

- Power Plant

- Oil & Gas

- Cement

- Chemical

- Fertilizers

- Sugar

- Petrochemical

- Refineries

- Breweries

- Nuclear Power

- Paper

- Weld Neck Flange For Hydrotest

- Weld Neck Flange For Pressure Test

|

- Offshore

- Mining

- Construction

- Shipbuilding

- Engineering Co. &

- Oil Mills

- Steel Plant

- Railway

- Defence

- Ports

- Government Org. etc.

- Weld Neck Flange For Hdpe Pipe

- Weld Neck Flange Oil And Gas

|

Stock Of Weld Neck Flange

- Slip Weld Neck Flange

- Tapped Weld Neck Flange

- Paddle Weld Neck Flange

- Victaulic Weld Neck Flange

- Api Weld Neck Flange

- Asme Weld Neck Flange

- Aluminum Weld Neck Flange

- Weld Neck Flange Asme B16.5

- Weld Neck Flange A105

- Weld Neck flange vs weld neck flange

- Weld Neck Flange Asme

- Weld Neck Flange Awwa C207 Class D

- Weld Neck Flange Api 6a

- Weld Neck Flange Ansi 600

- Weld Neck Flange B16.5

- Weld Neck Flange Bolts

- Grayloc Weld Neck Flange

- Weld Neck Flange Hdpe

- Weld Neck Flange Hub

- Weld Neck Flange With Tap

- Weld Neck Flange With Hole

- Weld Neck Flange Water Main

- Weld Neck Flange With Drain

- Weld Neck Flange With Hub

- Weld Neck Flange Tapped

- Weld Neck Flange Vessel

- Blind Orifice Flange

- Weld Neck Flange Slip On

- Weld Neck Flange Ring Type Joint

- Harga Weld Neck Flange Jis 10k

- Jual Weld Neck Flange

- Weld Neck Flange Pipe

- Weld Neck Flange Pn16

- Weld Neck Flange Plate

- Weld Neck Flange Raised Face

- Weld Neck Flange Rtj

|

- Weld Neck Flange En 1092-1

- Weld Neck Flange En 1092

- Weld Neck Flange End Connection

- Weld Neck Flange Din En 1092-1

- Weld Neck Flange Face

- Weld Neck Flange Class 150

- Weld Neck Flange Cap

- Weld Neck Flange Carbon Steel

- Weld Neck Flange Class 300

- Weld Neck Flange Class 600

- Weld Neck Flange Drilled And Tapped

- Weld Neck Flange B16.47

- Weld Neck Flange Brass

- Weld Neck Flange With Bleed Valve

- Weld Neck Flange Series B

- Weld Neck Flange Asme B16.5 Class 300

- Kf Weld Neck Flange

- Weld Neck Flange Lifting Device

- Weld Neck Flange Lifting Lug

- Weld Neck Flange Lockout

- Weld Neck Flange Npt

- Weld Neck Flange Nozzle

- Weld Neck Flange Nps

- Weld Neck Flange Need Gasket

- Weld Neck Flange With Npt Tap

- Weld Neck Flange With Npt Thread

- Weld Neck Flange With Npt Hole

- Weld Neck Flange Od Chart

- Weld Neck Flange On P&Id

- Weld Neck Flange Ring Type Joint

- Weld Neck Flange Rtj 900

- Weld Neck Flange Rtj 1500

- Weld Neck Flange Rtj 2500

- Weld Neck Flange Need Gasket

- Blind Kidney Flange

- Weld Neck Flange Plumbing

|

MARKING & PACKING

Our products like flanges are packaged to make sure that there’s no damage throughout transit. Just in case of exports, customary export packaging is completed in wooden boxes or cases. All flanges are marked with Trademark (SSI LOGO), Grade, Size and Lot No. On requests we can do custom marking on our products.

TEST CERTIFICATES

Manufacturer Test Certificate as per EN 10204-3.1, EN 10204-3.2, Raw Materials Certificate, NABL approved Lab Test Report, 100% Radiography Test Report, Third Party Inspection Report etc.