Stainless Steel 316 Blind Flange Manufacturers In India

Introduction to Stainless Steel 316 Blind Flanges

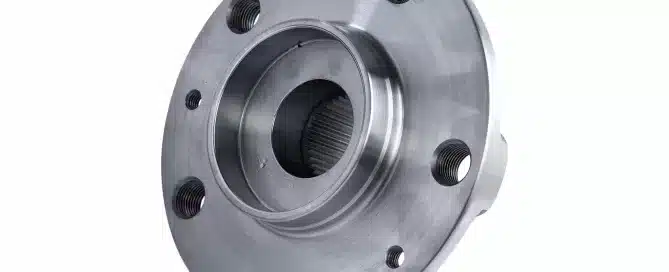

In the world of industrial components, stainless steel 316 blind flanges hold a significant place. These essential fittings are used to block off the ends of pipelines, valves, or pressure vessel openings, ensuring that no fluid passes through. Their applications span across various industries, including oil and gas, petrochemicals, and marine engineering. Understanding the importance of high-quality blind flanges can save industries from potential hazards and inefficiencies.

Blind flanges made from stainless steel 316 are especially revered for their robustness and resistance to corrosion, making them ideal for harsh environments. They provide a reliable sealing solution, preventing leaks and maintaining the integrity of the entire pipeline system. This blog post will guide you through the nuances of stainless steel 316 blind flanges, focusing on why Sachiya Steel International Private Limited is a top manufacturer in India.

By the end of this post, you will have a comprehensive understanding of the specifications, benefits, and manufacturing excellence associated with stainless steel 316 blind flanges. Let’s begin this insightful exploration.

Stainless Steel 316 Blind Flange Specifications Table

|

Specification

|

Details

|

|

Material

|

Stainless Steel 316

|

|

Type

|

Blind Flange

|

|

Standard

|

ASME B16.5, ANSI/ASME

|

|

Size Range

|

1/2 inch to 60 inches

|

|

Thickness Range

|

1/4 inch to 2 inches

|

|

Pressure Rating

|

Class 150, Class 300, Class 600

|

|

Finish

|

Smooth, Polish (Grain 120 to 320)

|

|

Connection Type

|

Bolt and Gasket

|

|

Temperature Range

|

Up to 870°C (1600°F)

|

|

Applications

|

Oil & Gas, Petrochemicals, Marine Engineering, Power Plants

|

This table serves as a concise reference to the critical specifications of stainless steel 316 blind flanges, aiding professionals in selecting the appropriate component for their specific applications.

A Closer Look at Sachiya Steel International Private Limited

Sachiya Steel International Private Limited stands as a beacon of quality and innovation in the manufacturing sector. Known for its expertise in producing stainless steel 316 blind flanges, the company has carved a niche for itself in both domestic and international markets. Their commitment to precision engineering and customer satisfaction sets them apart from other manufacturers.

This company prides itself on employing advanced technologies and adhering to stringent quality control measures. With a dedicated team of engineers and industry experts, Sachiya Steel International consistently delivers products that exceed expectations. Their comprehensive range of blind flanges caters to various industrial needs, proving their capability to handle demanding projects.

Among their notable achievements, Sachiya Steel has been recognized for its rapid turnaround times and ability to customize products according to client specifications. This flexibility and dedication to quality make them a preferred choice for industrial buyers and distributors worldwide.

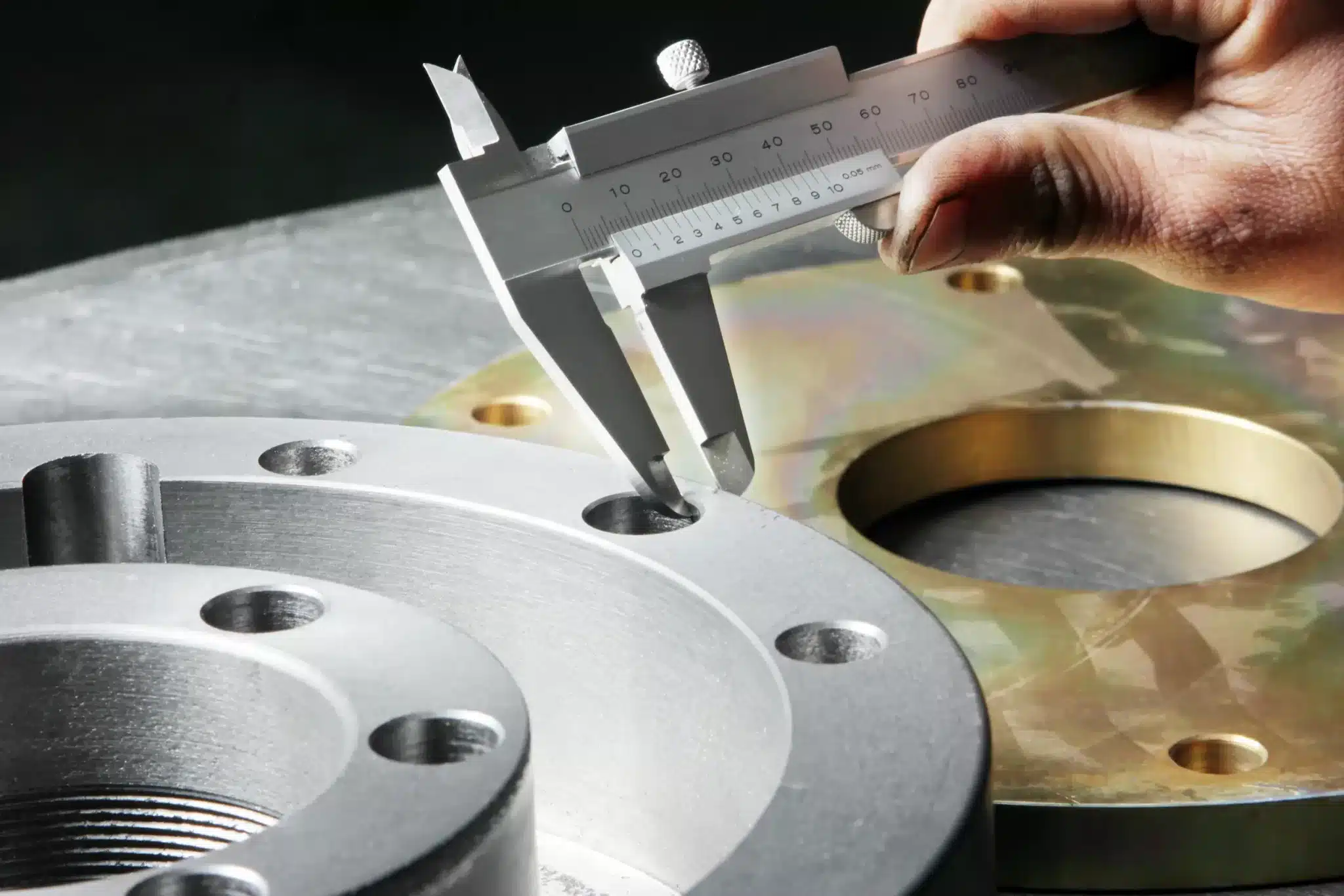

Quality Assurance and Certifications

Quality assurance is the backbone of Sachiya Steel International’s operations. The company adheres to rigorous standards to ensure that every stainless steel 316 blind flange meets the highest industry benchmarks. Their commitment to excellence is reflected in their numerous certifications and compliance with international quality standards.

Sachiya Steel holds certifications such as ISO 9001, which underscores their dedication to quality management systems. Additionally, they conform to ASTM, ASME, and ANSI standards, ensuring that their products are globally recognized and accepted. These certifications are not just accolades but a testament to their relentless pursuit of perfection.

The company’s quality assurance process involves multiple stages of inspection and testing. From raw material procurement to final product delivery, each step is meticulously monitored. Non-destructive testing (NDT) methods are employed to detect any potential flaws, ensuring that only flawless products reach the customers.

Advantages of Stainless Steel 316

Stainless steel 316 is renowned for its superior qualities, making it an ideal material for manufacturing blind flanges. One of its most significant advantages is its exceptional resistance to corrosion. This grade of stainless steel contains molybdenum, which enhances its ability to withstand corrosive environments, including those with high salinity and industrial chemicals.

Durability is another hallmark of stainless steel 316. It can endure extreme temperatures, both high and low, without losing its structural integrity. This makes it suitable for applications in industries such as oil and gas, where components are exposed to harsh operational conditions.

Additionally, stainless steel 316 is known for its excellent mechanical properties. It offers high tensile and yield strength, ensuring that the blind flanges can handle substantial pressure and weight. This reliability is crucial for maintaining the safety and efficiency of industrial systems.

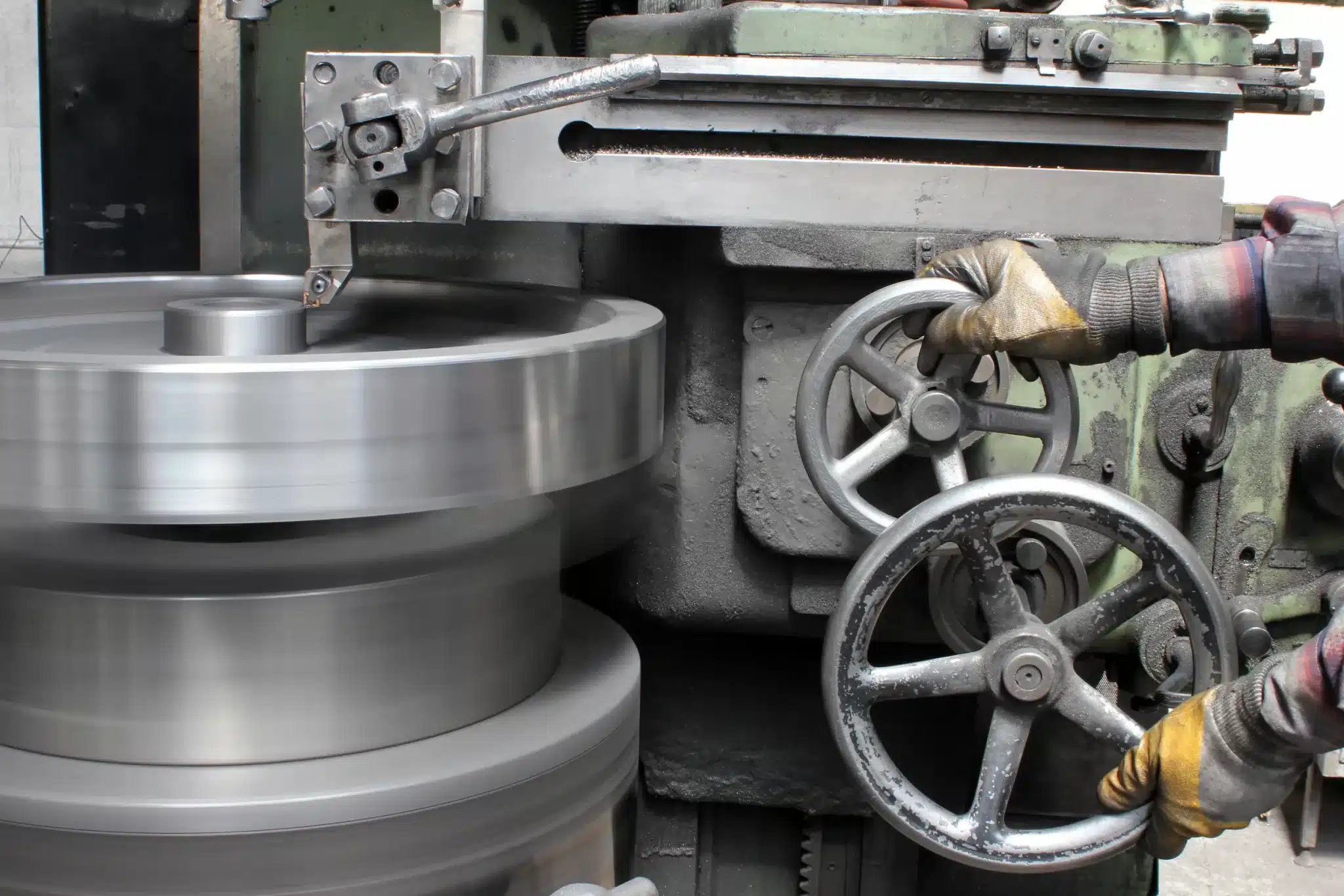

Manufacturing Process

Sachiya Steel International employs a sophisticated manufacturing process to produce stainless steel 316 blind flanges. This process begins with selecting high-quality raw materials, sourced from reputable suppliers. The raw stainless steel undergoes a series of treatments to enhance its properties and prepare it for fabrication.

Forging is a critical step in the manufacturing process. It involves shaping the stainless steel under high pressure to form the blind flange. This method ensures that the material’s grain structure is enhanced, resulting in increased strength and durability. The forged flanges are then subjected to precision machining to achieve the desired dimensions and surface finish.

Heat treatment is another essential stage. By carefully controlling the heating and cooling cycles, the mechanical properties of the stainless steel are optimized. This process enhances the flange’s hardness, toughness, and resistance to wear and tear. Finally, the blind flanges are thoroughly inspected and tested to ensure they meet all quality standards before being dispatched to customers.

Chemical Properties of Stainless Steel 316 Blind Flange

|

Element

|

Composition (%)

|

|

Chromium (Cr)

|

16.0 – 18.0

|

|

Nickel (Ni)

|

10.0 – 14.0

|

|

Molybdenum (Mo)

|

2.0 – 3.0

|

|

Carbon (C)

|

≤ 0.08

|

|

Silicon (Si)

|

≤ 1.0

|

|

Manganese (Mn)

|

≤ 2.0

|

|

Phosphorus (P)

|

≤ 0.045

|

|

Sulfur (S)

|

≤ 0.030

|

|

Iron (Fe)

|

Balance

|

Mechanical Properties of Stainless Steel 316 Blind Flange

|

Property

|

Value

|

|

Density

|

8.0 g/cm³

|

|

Ultimate Tensile Strength

|

560 MPa (80,000 psi)

|

|

Yield Strength

|

290 MPa (42,000 psi)

|

|

Modulus of Elasticity

|

193 GPa (28 x 10³ ksi)

|

|

Elongation

|

40%

|

|

Hardness (Brinell)

|

150 HB

|

|

Hardness (Rockwell)

|

B70

|

|

Poisson’s Ratio

|

0.3

|

These tables provide a detailed overview of the chemical and mechanical properties of stainless steel 316, enabling engineers and industry professionals to understand the performance characteristics of blind flanges constructed from this high-quality material.

Key Features of Sachiya Steel’s Blind Flanges

Sachiya Steel’s stainless steel 316 blind flanges boast several key features that set them apart from competitors. Firstly, their flanges are designed with precision and accuracy, ensuring a perfect fit and seamless integration into various pipeline systems. This reduces the risk of leaks and enhances the overall efficiency of the system.

Customization is another standout feature. Sachiya Steel understands that different industries have unique requirements, and they offer tailored solutions to meet these needs. Whether it’s specific dimensions, surface finishes, or additional features, the company can modify their flanges to suit individual customer demands.

Durability and longevity are also paramount. The stainless steel 316 used in their blind flanges is chosen for its ability to withstand extreme conditions. This means reduced maintenance costs and longer service life, providing excellent value for money. Additionally, the flanges come with comprehensive documentation, including material test reports and quality certificates, ensuring complete transparency and reliability.

Stainless Steel 316 Blind Flange Dimension Chart

The following table provides a comprehensive dimension chart for stainless steel 316 blind flanges, detailing various sizes, including nominal pipe sizes (NPS), outer diameters (OD), thicknesses, and bolt hole specifications.

|

Nominal Pipe Size (NPS)

|

Outer Diameter (OD)

|

Thickness

|

Number of Holes

|

Bolt Circle Diameter (BCD)

|

Hole Size

|

|

1/2

|

3.0 in

|

0.5 in

|

4

|

2.5 in

|

0.25 in

|

|

3/4

|

3.5 in

|

0.5 in

|

4

|

2.75 in

|

0.25 in

|

|

1

|

4.0 in

|

0.5 in

|

4

|

3.0 in

|

0.25 in

|

|

1.5

|

5.0 in

|

0.5 in

|

4

|

4.0 in

|

0.25 in

|

|

2

|

6.0 in

|

0.5 in

|

4

|

4.5 in

|

0.25 in

|

|

2.5

|

7.0 in

|

0.5 in

|

4

|

5.5 in

|

0.25 in

|

|

3

|

8.0 in

|

0.5 in

|

4

|

6.5 in

|

0.25 in

|

|

4

|

9.0 in

|

0.5 in

|

8

|

8.0 in

|

0.25 in

|

|

5

|

10.0 in

|

0.5 in

|

8

|

9.0 in

|

0.25 in

|

|

6

|

11.0 in

|

0.5 in

|

8

|

10.0 in

|

0.25 in

|

|

8

|

13.0 in

|

0.5 in

|

8

|

12.0 in

|

0.25 in

|

|

10

|

15.0 in

|

0.5 in

|

12

|

14.0 in

|

0.31 in

|

|

12

|

17.0 in

|

0.5 in

|

12

|

16.0 in

|

0.31 in

|

|

14

|

19.0 in

|

0.5 in

|

12

|

18.0 in

|

0.31 in

|

|

16

|

21.0 in

|

0.5 in

|

12

|

20.0 in

|

0.31 in

|

|

18

|

23.0 in

|

0.5 in

|

12

|

22.0 in

|

0.31 in

|

|

20

|

25.0 in

|

0.5 in

|

12

|

24.0 in

|

0.31 in

|

|

24

|

29.0 in

|

0.5 in

|

12

|

28.0 in

|

0.31 in

|

|

30

|

36.0 in

|

0.5 in

|

12

|

34.0 in

|

0.31 in

|

This dimension chart serves as a reference for engineers and procurement specialists seeking precise measurements for stainless steel 316 blind flanges, ensuring compatibility and optimal performance in various applications.

Ready Stock Stainless Steel 316 Blind Flange

The following table lists the ready stock specifications for Sachiya Steel’s stainless steel 316 blind flanges, providing essential information on availability, dimensions, and inventory levels.

|

Nominal Pipe Size (NPS)

|

Outer Diameter (OD)

|

Thickness

|

Number of Holes

|

Bolt Circle Diameter (BCD)

|

Hole Size

|

Stock Level

|

|

1/2

|

3.0 in

|

0.5 in

|

4

|

2.5 in

|

0.25 in

|

Available

|

|

3/4

|

3.5 in

|

0.5 in

|

4

|

2.75 in

|

0.25 in

|

Available

|

|

1

|

4.0 in

|

0.5 in

|

4

|

3.0 in

|

0.25 in

|

Limited

|

|

1.5

|

5.0 in

|

0.5 in

|

4

|

4.0 in

|

0.25 in

|

Available

|

|

2

|

6.0 in

|

0.5 in

|

4

|

4.5 in

|

0.25 in

|

Available

|

|

2.5

|

7.0 in

|

0.5 in

|

4

|

5.5 in

|

0.25 in

|

Limited

|

|

3

|

8.0 in

|

0.5 in

|

4

|

6.5 in

|

0.25 in

|

Available

|

|

4

|

9.0 in

|

0.5 in

|

8

|

8.0 in

|

0.25 in

|

Available

|

|

5

|

10.0 in

|

0.5 in

|

8

|

9.0 in

|

0.25 in

|

Limited

|

|

6

|

11.0 in

|

0.5 in

|

8

|

10.0 in

|

0.25 in

|

Available

|

|

8

|

13.0 in

|

0.5 in

|

8

|

12.0 in

|

0.25 in

|

Available

|

|

10

|

15.0 in

|

0.5 in

|

12

|

14.0 in

|

0.31 in

|

Limited

|

|

12

|

17.0 in

|

0.5 in

|

12

|

16.0 in

|

0.31 in

|

Available

|

|

14

|

19.0 in

|

0.5 in

|

12

|

18.0 in

|

0.31 in

|

Available

|

|

16

|

21.0 in

|

0.5 in

|

12

|

20.0 in

|

0.31 in

|

Limited

|

|

18

|

23.0 in

|

0.5 in

|

12

|

22.0 in

|

0.31 in

|

Available

|

|

20

|

25.0 in

|

0.5 in

|

12

|

24.0 in

|

0.31 in

|

Available

|

|

24

|

29.0 in

|

0.5 in

|

12

|

28.0 in

|

0.31 in

|

Limited

|

|

30

|

36.0 in

|

0.5 in

|

12

|

34.0 in

|

0.31 in

|

Available

|

This ready stock table is a valuable resource for customers and procurement departments, ensuring quick access to essential product information and assisting in prompt decision-making for purchase orders.

Case Studies and Testimonials

Real-life applications of Sachiya Steel’s products provide valuable insights into their performance and reliability. One notable case study involves a leading oil refinery that faced frequent pipeline leaks due to substandard flanges. After switching to Sachiya Steel’s stainless steel 316 blind flanges, the refinery reported a significant reduction in maintenance issues and operational downtime.

Testimonials from satisfied customers further highlight the company’s excellence. “Sachiya Steel’s blind flanges are unmatched in quality. Their attention to detail and commitment to customer satisfaction have made them our go-to supplier,” says an engineering manager at a major petrochemical company. Such feedback underscores the trust and confidence that industry professionals place in Sachiya Steel’s products.

Another customer, a distributor in Europe, praised the company’s responsiveness and flexibility. “We often have specific requirements, and Sachiya Steel always delivers customized solutions promptly. Their products consistently meet our high standards.”

The Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for stainless steel 316 blind flanges is critical for ensuring the safety and efficiency of industrial operations. A reputable manufacturer like Sachiya Steel International guarantees that their products meet stringent quality standards and are free from defects. This reliability translates into fewer maintenance issues and lower operational risks.

A trustworthy manufacturer also offers comprehensive support and after-sales service. From technical assistance during installation to prompt resolution of any issues, having a reliable partner can make a significant difference. Sachiya Steel’s commitment to customer satisfaction ensures that clients receive the best possible service throughout the product lifecycle.

Additionally, choosing a manufacturer with a strong track record and industry recognition provides peace of mind. Sachiya Steel’s numerous certifications and positive testimonials reflect their dedication to quality and excellence. For industrial buyers and engineers, this assurance is invaluable.

Countries Where Sachiya Steel Exports Stainless Steel 316 Blind Flanges

Sachiya Steel International has established a robust global presence, exporting stainless steel 316 blind flanges to a wide array of countries. The following is a list of key markets where these high-quality products are available:

- United States

- Canada

- Mexico

- United Kingdom

- Germany

- France

- Italy

- Spain

- Netherlands

- Australia

- South Africa

- United Arab Emirates

- Saudi Arabia

- India

- Japan

- South Korea

- Singapore

- Brazil

- Argentina

- Indonesia

This extensive export network showcases the company’s commitment to providing reliable and durable stainless steel solutions to diverse industries worldwide, ensuring that clients receive exceptional performance no matter the location.

Conclusion

Stainless steel 316 blind flanges are indispensable components in various industries, offering unmatched durability and corrosion resistance. Sachiya Steel International Private Limited stands out as a leading manufacturer, known for its commitment to quality, customization, and customer satisfaction.

In this comprehensive guide, we have explored the significance of stainless steel 316 blind flanges, the manufacturing excellence of Sachiya Steel, and the critical factors to consider when choosing a manufacturer. By opting for high-quality products from a reputable supplier, industrial buyers and engineers can ensure the efficiency and safety of their operations.

If you are looking to enhance your industrial systems with superior stainless steel 316 blind flanges, consider partnering with Sachiya Steel International. Their expertise and dedication to excellence will provide you with reliable solutions tailored to your specific needs. Contact them today to learn more about their offerings and how they can support your projects.