Stainless Steel 410 Weld Neck Flange Manufacturers In India

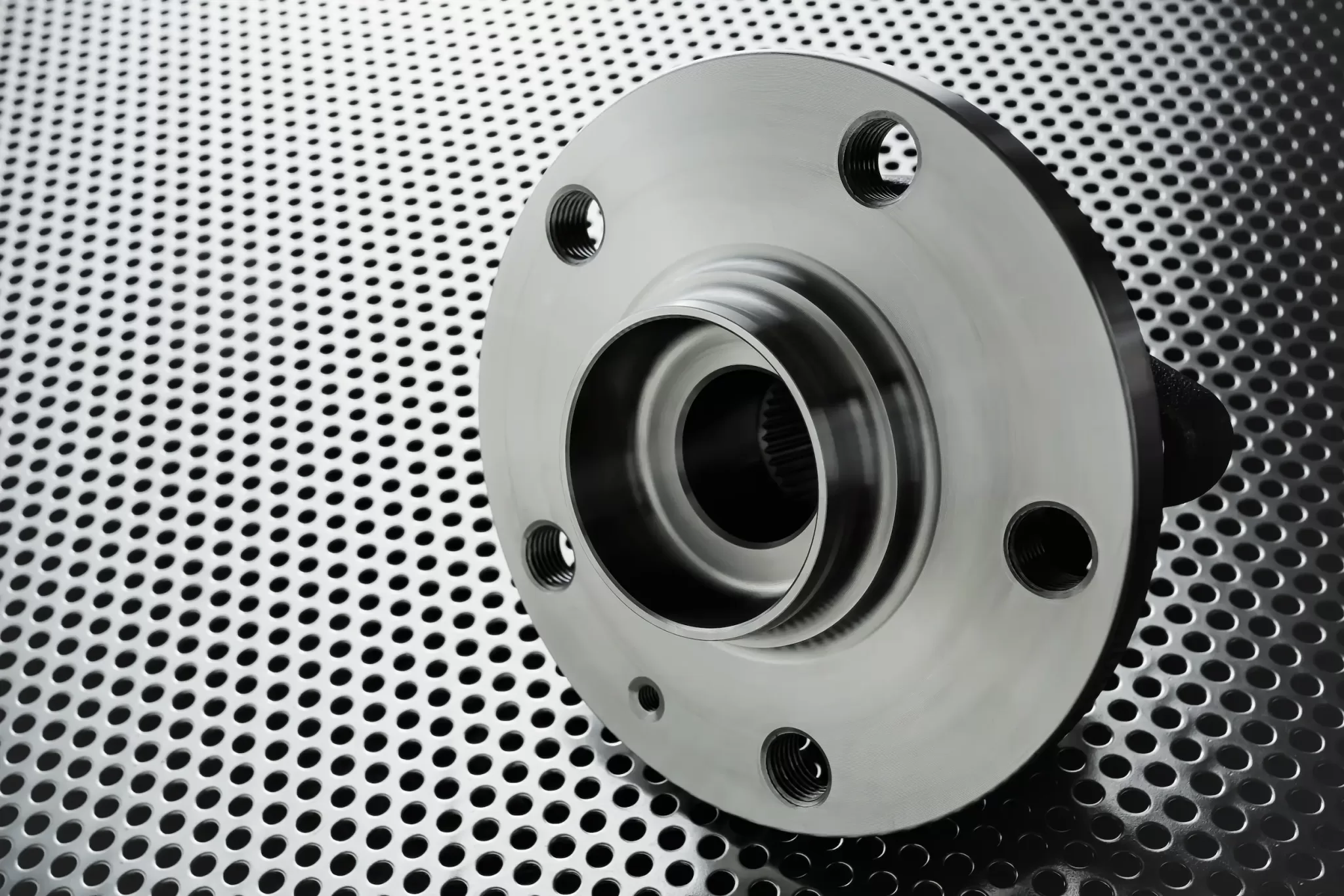

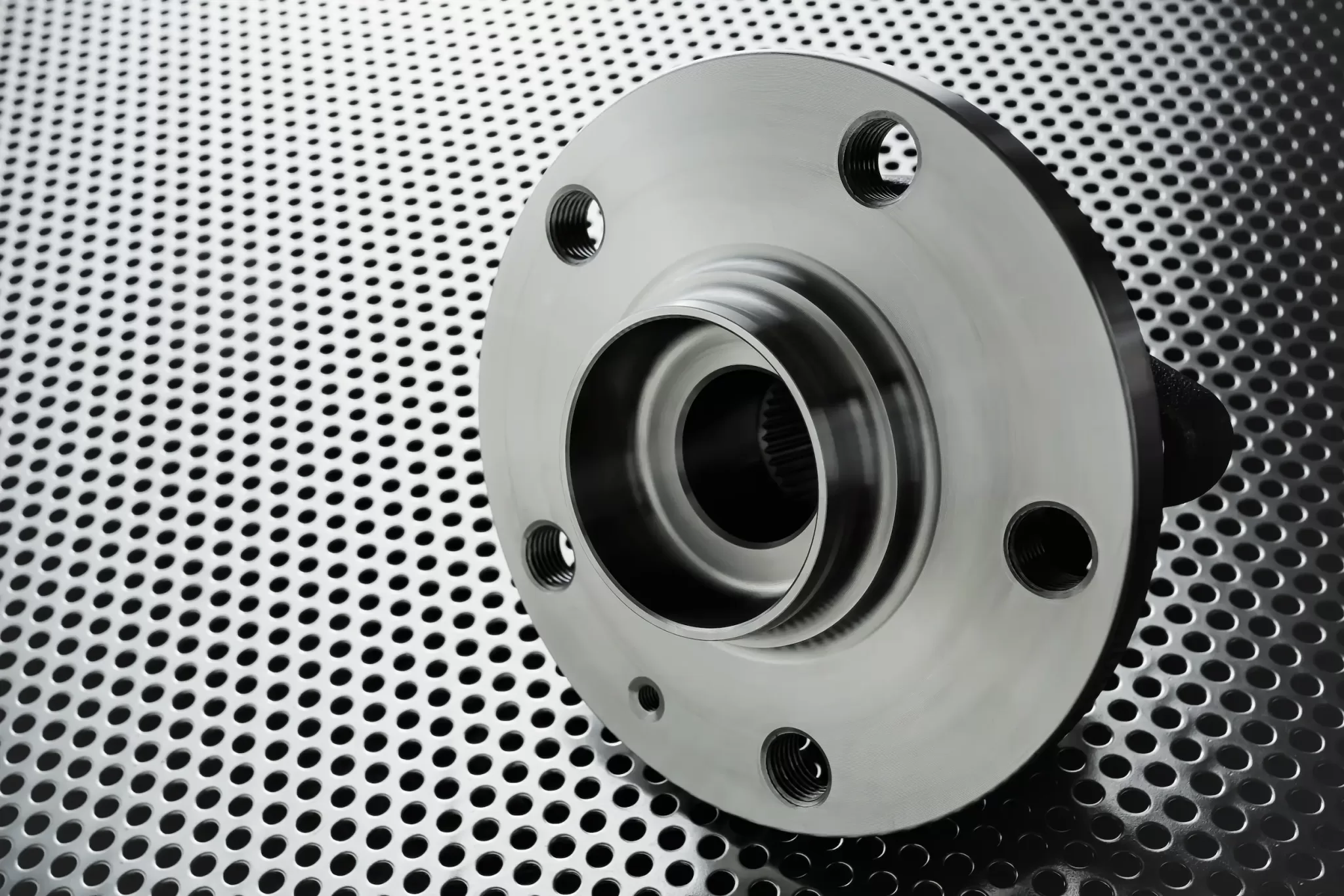

Introduction to Stainless Steel 410 Weld Neck Flanges

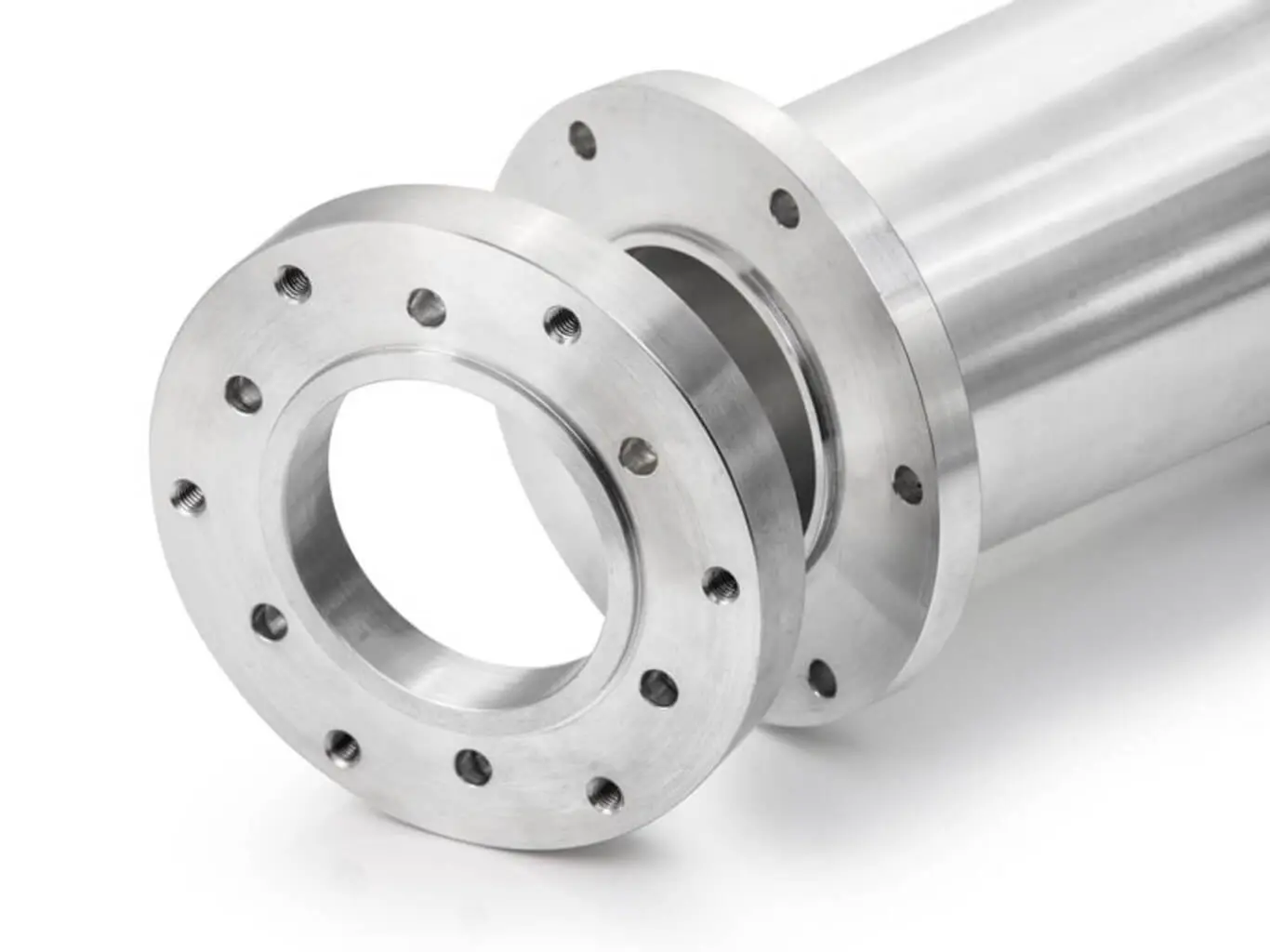

In the robust world of steel and engineering, certain components stand out for their sheer utility and performance. One such indispensable component is the weld neck flange. These flanges play a vital role in complex piping systems, ensuring secure connections and optimal performance. When crafted from Stainless Steel 410, these weld neck flanges offer an unmatched combination of strength and resistance.

Stainless Steel 410 is a marvel in the steel industry due to its unique properties. Known for durability, corrosion resistance, and cost-effectiveness, it has become a preferred material for various industrial applications, especially in manufacturing weld neck flanges. This blog post explores why Stainless Steel 410 Weld Neck Flanges are highly regarded and how Sachiya Steel International Private Limited is leading the pack in manufacturing these critical components.

Specification Table for Stainless Steel 410 Weld Neck Flanges

|

Specification

|

Details

|

|

Size Range

|

½” to 24″

|

|

Pressure Class

|

150#, 300#, 600#, 900#, 1500#, 2500#

|

|

Dimensions

|

ANSI B16.5, ASME B16.47, DIN, and EN

|

|

Face Type

|

Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

|

|

Flange Facing

|

FF, RF, RTJ

|

|

Connection Type

|

Weld Neck

|

|

End Type

|

Beveled End

|

|

Thickness

|

SCH 10, SCH 40, SCH 80, SCH 160, XXS

|

|

Industry Standards

|

ASTM A182, ASME SA182

|

By incorporating these specifications into your system designs, you ensure that you are using components crafted to meet stringent industrial standards, resulting in reliable and high-performing infrastructure.

Sachiya Steel International Private Limited: A Leader in Manufacturing

Sachiya Steel International Private Limited has steadily carved a niche for itself in the steel industry. Since its inception, the company has focused on delivering high-quality products tailored to meet the needs of various sectors.

With a rich history of innovation and commitment to excellence, Sachiya Steel International stands as a beacon of quality and reliability. Our core values revolve around customer satisfaction, ethical practices, and continuous improvement. These principles have propelled us to the forefront of the industry, making us India’s leading manufacturer of Stainless Steel 410 Weld Neck Flanges.

Understanding Stainless Steel 410 and Its Benefits

Stainless Steel 410 is a martensitic stainless steel that combines strength, hardness, and corrosion resistance. These properties make it an ideal choice for manufacturing robust and durable weld neck flanges.

Properties that Make it Ideal for Flange Manufacturing

Stainless Steel 410 is known for its impressive tensile strength and hardness, which ensures that the flanges can withstand high pressure and mechanical stress.

While not as corrosion-resistant as some other stainless steel grades, Stainless Steel 410 offers adequate resistance to corrosion in mild environments, which is often sufficient for many industrial applications.

Compared to austenitic stainless steels, Stainless Steel 410 is more economical, providing a cost-effective solution without compromising on performance.

How it Compares to Other Stainless Steel Grades

When compared to other stainless steel grades, Stainless Steel 410 stands out for its balance of performance and cost. Unlike the more expensive austenitic grades like 304 and 316, 410 offers sufficient corrosion resistance and mechanical properties for many applications, making it an attractive option for manufacturers looking to optimize performance and budget.

Price List for Stainless Steel 410 Weld Neck Flange

The following price list provides detailed pricing information for Stainless Steel 410 Weld Neck Flanges. Prices are listed in both INR and USD to cater to our diverse global clientele. Each size and schedule has been meticulously priced to ensure competitive and transparent pricing.

|

Size

|

Pressure Class

|

Thickness

|

Price (INR)

|

Price (USD)

|

|

½”

|

150#

|

SCH 10

|

₹ 300

|

$ 4.00

|

|

½”

|

150#

|

SCH 40

|

₹ 320

|

$ 4.25

|

|

½”

|

300#

|

SCH 40

|

₹ 350

|

$ 4.60

|

|

1″

|

150#

|

SCH 10

|

₹ 450

|

$ 6.00

|

|

1″

|

150#

|

SCH 40

|

₹ 480

|

$ 6.40

|

|

1″

|

300#

|

SCH 40

|

₹ 520

|

$ 6.90

|

|

2″

|

150#

|

SCH 10

|

₹ 800

|

$ 10.70

|

|

2″

|

150#

|

SCH 40

|

₹ 850

|

$ 11.35

|

|

2″

|

300#

|

SCH 40

|

₹ 900

|

$ 12.00

|

|

3″

|

150#

|

SCH 10

|

₹ 1,200

|

$ 16.00

|

|

3″

|

150#

|

SCH 40

|

₹ 1,280

|

$ 17.00

|

|

3″

|

300#

|

SCH 40

|

₹ 1,360

|

$ 18.00

|

|

4″

|

150#

|

SCH 10

|

₹ 1,800

|

$ 24.00

|

|

4″

|

150#

|

SCH 40

|

₹ 1,900

|

$ 25.30

|

|

4″

|

300#

|

SCH 40

|

₹ 2,000

|

$ 26.70

|

|

6″

|

150#

|

SCH 10

|

₹ 2,800

|

$ 37.30

|

|

6″

|

150#

|

SCH 40

|

₹ 2,950

|

$ 39.30

|

|

6″

|

300#

|

SCH 40

|

₹ 3,100

|

$ 41.30

|

|

8″

|

150#

|

SCH 10

|

₹ 4,000

|

$ 53.30

|

|

8″

|

150#

|

SCH 40

|

₹ 4,250

|

$ 56.70

|

|

8″

|

300#

|

SCH 40

|

₹ 4,500

|

$ 60.00

|

|

10″

|

150#

|

SCH 10

|

₹ 5,600

|

$ 74.70

|

|

10″

|

150#

|

SCH 40

|

₹ 6,000

|

$ 80.00

|

|

10″

|

300#

|

SCH 40

|

₹ 6,400

|

$ 85.30

|

|

12″

|

150#

|

SCH 10

|

₹ 7,800

|

$ 104.00

|

|

12″

|

150#

|

SCH 40

|

₹ 8,350

|

$ 111.30

|

|

12″

|

300#

|

SCH 40

|

₹ 8,900

|

$ 118.70

|

|

14″

|

150#

|

SCH 10

|

₹ 9,500

|

$ 126.70

|

|

14″

|

150#

|

SCH 40

|

₹ 10,200

|

$ 136.00

|

|

14″

|

300#

|

SCH 40

|

₹ 10,800

|

$ 144.00

|

|

16″

|

150#

|

SCH 10

|

₹ 11,500

|

$ 153.30

|

|

16″

|

150#

|

SCH 40

|

₹ 12,300

|

$ 164.00

|

|

16″

|

300#

|

SCH 40

|

₹ 13,100

|

$ 174.70

|

|

18″

|

150#

|

SCH 10

|

₹ 13,500

|

$ 180.00

|

|

18″

|

150#

|

SCH 40

|

₹ 14,400

|

$ 192.00

|

|

18″

|

300#

|

SCH 40

|

₹ 15,300

|

$ 204.00

|

|

20″

|

150#

|

SCH 10

|

₹ 15,500

|

$ 206.70

|

|

20″

|

150#

|

SCH 40

|

₹ 16,600

|

$ 221.30

|

|

20″

|

300#

|

SCH 40

|

₹ 17,700

|

$ 236.00

|

|

24″

|

150#

|

SCH 10

|

₹ 18,500

|

$ 246.70

|

|

24″

|

150#

|

SCH 40

|

₹ 19,800

|

$ 264.00

|

|

24″

|

300#

|

SCH 40

|

₹ 21,000

|

$ 280.00

|

By offering transparent and competitive pricing, Sachiya Steel International Private Limited ensures that our clients have access to high-quality Stainless Steel 410 Weld Neck Flanges at the best possible prices.

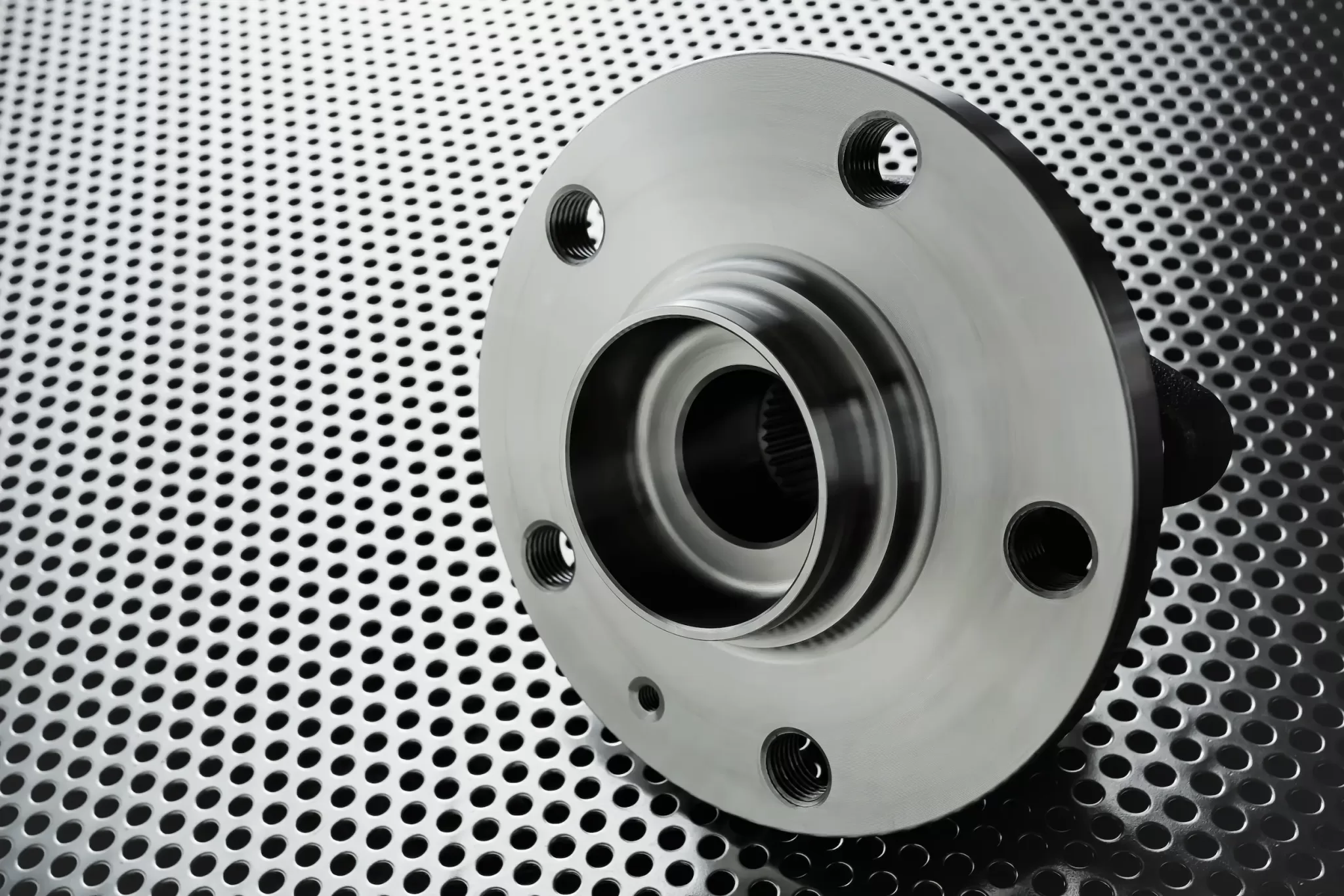

The Manufacturing Process of Stainless Steel 410 Weld Neck Flanges

Creating high-quality weld neck flanges from Stainless Steel 410 involves a meticulous manufacturing process designed to ensure precision and durability.

Detailed Steps from Raw Material to Finished Product

- Raw Material Selection:

High-quality Stainless Steel 410 is sourced to ensure the best possible starting point for manufacturing.

- Forging:

The steel is heated and shaped into the basic form of the flange through forging, a process that enhances the material’s strength.

- Machining:

Precision machining techniques are employed to achieve the exact dimensions and specifications required for the weld neck flange.

- Heat Treatment:

Heat treatment processes such as annealing are applied to improve the mechanical properties of the flange.

- Finishing:

The flange undergoes surface finishing to enhance its appearance and resistance to environmental factors.

Quality Control Measures in Place

At Sachiya Steel International, rigorous quality control measures are integrated into every step of the manufacturing process. Stringent inspections and testing protocols ensure that each flange meets the highest standards of quality and performance. From dimensional accuracy to mechanical strength, every aspect is scrutinized to deliver a product that our clients can trust.

Chemical Properties of Stainless Steel 410 Weld Neck Flange

The composition of Stainless Steel 410 is tailored to provide a balance of strength, hardness, and corrosion resistance. Below is the typical chemical composition of Stainless Steel 410:

|

Element

|

Composition (%)

|

|

Carbon (C)

|

0.08 – 0.15

|

|

Manganese (Mn)

|

1.00 max

|

|

Phosphorus (P)

|

0.040 max

|

|

Sulfur (S)

|

0.030 max

|

|

Silicon (Si)

|

1.00 max

|

|

Chromium (Cr)

|

11.50 – 13.50

|

|

Nickel (Ni)

|

0.75 max

|

|

Iron (Fe)

|

Balance

|

The specific chemical properties ensure that the Stainless Steel 410 can deliver robust performance in various industrial applications.

Mechanical Properties of Stainless Steel 410 Weld Neck Flange

In addition to its chemical properties, the mechanical properties of Stainless Steel 410 are critical to its performance in demanding environments. Below are the typical mechanical properties:

|

Property

|

Value

|

|

Tensile Strength

|

450 – 650 MPa

|

|

Yield Strength

|

205 MPa min

|

|

Elongation

|

20% min

|

|

Hardness (Rockwell C)

|

20 – 25 HRC

|

|

Impact Toughness

|

20 J min

|

These mechanical properties highlight the material’s ability to withstand high-pressure environments and mechanical stress, ensuring long-lasting performance and reliability.

Applications and Industries that Benefit from These Flanges

Stainless Steel 410 Weld Neck Flanges find their utility in a diverse array of industries, thanks to their robustness and reliability.

Highlight Sectors Where These Flanges Are Commonly Used

These flanges are critical in the oil and gas industry, where they are used in pipelines and drilling equipment, providing secure and leak-proof connections.

The chemical industry benefits from the corrosion-resistant properties of Stainless Steel 410, making these flanges ideal for use in harsh chemical environments.

In power plants, weld neck flanges are essential for connecting pipes in high-pressure steam systems and other critical infrastructure.

Success Stories or Case Studies from Previous Clients

One of our clients in the oil and gas sector reported significant improvements in operational efficiency after switching to our Stainless Steel 410 Weld Neck Flanges. The enhanced durability and reduced maintenance needs translated into lower operational costs and increased uptime, showcasing the tangible benefits of our high-quality flanges.

Dimension Chart for Stainless Steel 410 Weld Neck Flange

The following dimension chart provides detailed measurements and information for the Stainless Steel 410 Weld Neck Flange across various sizes:

|

Nominal Pipe Size (inches)

|

Outside Diameter (OD) (mm)

|

Inside Diameter (ID) (mm)

|

Bolt Circle Diameter (BCD) (mm)

|

Number of Bolts

|

Size of Bolts (mm)

|

Thickness (mm)

|

Hub Height (mm)

|

Weight (kg)

|

|

1/2″

|

89

|

21.3

|

60.3

|

4

|

12.7

|

11.2

|

35

|

1.0

|

|

3/4″

|

98

|

26.7

|

69

|

4

|

12.7

|

12.7

|

38

|

1.5

|

|

1″

|

108

|

33.4

|

79.5

|

4

|

12.7

|

14.2

|

42

|

2.0

|

|

1-1/4″

|

117

|

42.1

|

89

|

4

|

15.9

|

15.7

|

44

|

2.8

|

|

1-1/2″

|

127

|

48.3

|

98.5

|

4

|

15.9

|

17.5

|

48

|

3.7

|

|

2″

|

152

|

60.3

|

120.5

|

4

|

19.1

|

19.0

|

51

|

5.5

|

|

2-1/2″

|

178

|

73.0

|

139.5

|

4

|

19.1

|

23.9

|

57

|

7.5

|

|

3″

|

190

|

88.9

|

152.5

|

4

|

19.1

|

23.9

|

61

|

8.6

|

|

4″

|

229

|

114.3

|

190.5

|

8

|

19.1

|

23.9

|

66

|

13.1

|

|

5″

|

254

|

141.3

|

216

|

8

|

22.2

|

23.9

|

72

|

15.5

|

|

6″

|

279

|

168.3

|

241.5

|

8

|

22.2

|

25.4

|

80

|

18.9

|

|

8″

|

343

|

219.1

|

298.5

|

8

|

22.2

|

28.6

|

95

|

29.2

|

|

10″

|

406

|

273.1

|

362

|

12

|

25.4

|

30.2

|

108

|

42.2

|

|

12″

|

483

|

323.9

|

432

|

12

|

25.4

|

31.8

|

114

|

56.9

|

|

14″

|

533

|

355.6

|

476

|

12

|

28.6

|

36.5

|

121

|

68.0

|

|

16″

|

597

|

406.4

|

540

|

16

|

28.6

|

38.1

|

127

|

84.4

|

|

18″

|

635

|

457.2

|

578

|

16

|

31.8

|

41.3

|

133

|

97.1

|

|

20″

|

698

|

508

|

635

|

20

|

31.8

|

44.5

|

140

|

117.7

|

|

24″

|

813

|

609.6

|

749.5

|

20

|

35.0

|

47.8

|

152

|

150.5

|

This detailed dimension chart ensures that our clients have all the required information to select the appropriate weld neck flange for their specific needs, thereby ensuring optimal performance and reliability in their applications.

Advantages of Choosing Sachiya Steel International Private Limited

When it comes to choosing a supplier for Stainless Steel 410 Weld Neck Flanges, Sachiya Steel International stands out for several compelling reasons.

Competitive Pricing and On-Time Delivery

We understand the importance of cost management and timely delivery in industrial operations. Our competitive pricing ensures that you get the best value without compromising on quality. Additionally, our efficient logistics system guarantees that your orders are delivered on time, every time.

Customization Options and Dedicated Customer Support

At Sachiya Steel International, we believe in offering solutions tailored to your specific needs. Our customization options allow you to specify dimensions, finishes, and other requirements to suit your unique applications. Furthermore, our dedicated customer support team is always on hand to assist you with any queries or concerns, ensuring a seamless and satisfying experience.

Export Countries List for Stainless Steel 410 Weld Neck Flange

Below is a table detailing the countries to which we export Stainless Steel 410 Weld Neck Flanges:

|

Country

|

Continent

|

Industry Applications

|

|

United States

|

North America

|

Oil and Gas, Chemical Processing, Power Generation

|

|

Germany

|

Europe

|

Chemical Processing, Power Generation

|

|

United Kingdom

|

Europe

|

Oil and Gas, Chemical Processing

|

|

Saudi Arabia

|

Asia

|

Oil and Gas, Power Generation

|

|

Australia

|

Australia

|

Chemical Processing, Power Generation

|

|

Brazil

|

South America

|

Oil and Gas, Power Generation

|

|

Japan

|

Asia

|

Chemical Processing, Power Generation

|

|

South Korea

|

Asia

|

Oil and Gas, Chemical Processing

|

|

Canada

|

North America

|

Oil and Gas, Power Generation

|

|

South Africa

|

Africa

|

Chemical Processing, Power Generation

|

|

UAE

|

Asia

|

Oil and Gas, Chemical Processing

|

|

Mexico

|

North America

|

Oil and Gas, Chemical Processing

|

|

Italy

|

Europe

|

Oil and Gas, Power Generation

|

|

Spain

|

Europe

|

Chemical Processing, Power Generation

|

This comprehensive list underlines our global reach and commitment to supplying high-quality Stainless Steel 410 Weld Neck Flanges to a diverse range of industries and regions.

Conclusion

The Future of Stainless Steel 410 Weld Neck Flanges

Innovation and technology continue to drive advancements in the steel industry, and Stainless Steel 410 Weld Neck Flanges are at the forefront of this evolution. Their combination of strength, durability, and cost-effectiveness makes them an indispensable component across various sectors.

By choosing Sachiya Steel International Private Limited, you are partnering with a leader committed to quality, reliability, and customer satisfaction. We invite you to experience the difference our flanges can make in your operations. Explore our range of products and discover how we can help you achieve your goals.

For more information or to place an order, visit our website today and take the first step towards enhancing your industrial applications with the best in the business.