Stainless Steel Square Tubes Manufacturers In India

Stainless Steel Square Tubes Manufacturers In India

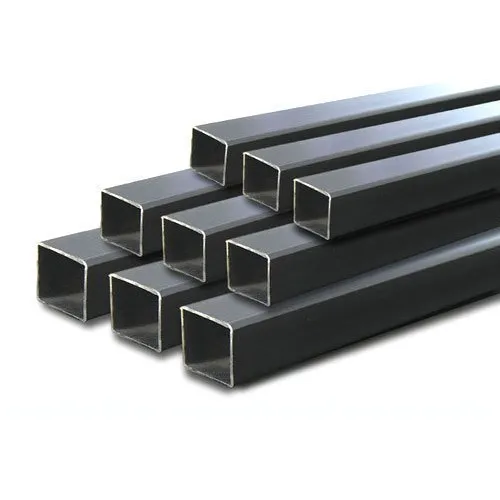

Stainless Steel Steel Square Tubes are a popular choice in the construction industry due to their excellent strength-to-weight ratio, durability, and versatility. They are used in a wide range of applications, including framing, structural support, and fencing, among others. Sachiya Steel International is a leading manufacturer of steel square tubes, offering high-quality products at competitive prices.

At Sachiya Steel International, we are committed to providing our customers with the highest quality steel square tubes. Our tubes are made from premium quality steel, which is sourced from trusted vendors in the market. We use the latest manufacturing techniques and equipment to ensure that our products are of the highest quality.

Specification Chart of Stainless Steel Square Tubes

| Pipe Size | 12.75 X 12.75, 15 X 15, 20 X 20, 25 X 25, 30 X 30, 40 X 40, 50 X 50, 60 X 60, 75 X 75, 80 X 80, 90 X 90, 100 X100 |

| Stainless Steel Square Pipe Grades | TP – 304/L/H, TP – 316/L/H/Ti, TP – 317L, TP – 321/H, TP – 347/H, 202, JT – 7, J4 – 1, TP – 409/L, TP – 410, TP – 430Ti, TP 439 |

| Stainless Steel Square

Pipe Standards |

ASTM A249 – A269 – A312 – A358 – A409 – A554 – A778 – A789 – A790 |

| TOLERANCE on Length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| Stainless Steel Square Pipe Finish | Polished Grit 120 – 600, Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm,Mirror Polished |

One of the key benefits of our steel square tubes is their strength. They are designed to withstand heavy loads and resist bending, which makes them ideal for use in construction applications. Our tubes are also resistant to corrosion, which means that they can be used in outdoor environments without the risk of rusting or degradation.

In addition to their strength and durability, our steel square tubes are also highly versatile. They can be cut, welded, and formed into a wide range of shapes and sizes, which makes them ideal for a variety of applications. Whether you need a standard size or a custom-made tube, we can provide you with the right solution to meet your needs.

At Sachiya Steel International, we pride ourselves on our commitment to customer satisfaction. We work closely with our customers to understand their unique needs and provide them with tailored solutions that meet their requirements. Our team of experts is always on hand to offer advice and support, ensuring that you get the right product for your project.

Jindal SS square tube Dimension Standard

| MM | 0.65 | 0.80 | 0.90 | 0.95 | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | |

| 12.5 x 12.5 | 0.075 | 0.091 | 0.102 | 0.107 | 0.112 | 0.133 | 0.163 | |||

| 20 x 20 | 0.176 | 0.184 | 0.220 | 0.271 | 0.354 | 0.433 | 0.508 | |||

| 25 x 25 | 0.221 | 0.232 | 0.277 | 0.343 | 0.450 | 0.553 | 0.652 | |||

| 30 x 30 | 0.267 | 0.280 | 0.335 | 0.415 | 0.516 | 0.673 | 0.796 | |||

| 38 x 38 | 0.340 | 0.358 | 0.427 | 0.531 | 0.700 | 0.866 | 1.027 | |||

| 40 x 40 | 0.358 | 0.376 | 0.450 | 0.559 | 0.738 | 0.898 | 1.084 | |||

| 50 x 50 | 0.473 | 0.565 | 0.703 | 0.930 | 1.153 | 1.372 |

Steel square tubes are a versatile and reliable choice for a wide range of construction applications. Whether you need a structural support for a building or a durable fence, Sachiya Steel International can provide you with the right product to meet your needs.

Our steel square tubes come in a range of sizes and thicknesses to suit your specific requirements. We can also provide custom sizes and lengths, so you can be sure that you are getting the right product for your project.

At Sachiya Steel International, we use only the highest quality steel in our manufacturing process. This ensures that our products are strong, durable, and long-lasting. Our tubes are also resistant to corrosion, which means that they can be used in harsh environments without the risk of rusting or degradation.

Standard Weight Chart of SS Square Welded Tube

| Square Hollow Section | Size | kg / m |

|---|---|---|

| Black SS Square Pipe | 12 x 12 x 1.5 mm | 0.59 |

| Silver SS Square Pipe | 15 x 15 x 1.2 mm | 0.54 |

| Welded Stainless Steel Square Pipe | 15 x 15 x 1.5 mm | 0.66 |

| Stainless Steel Box Pipe | 20 x 20 x 1.2 mm | 0.73 |

| Stainless Steel ERW Square Pipes | 20 x 20 x 1.5 mm | 0.90 |

| Stainless Steel Square Pipe | 20 x 20 x 2.0 mm | 0.18 |

| SS Square Pipe | 25 x 25 x 1.2 mm | 0.93 |

| Ferritic Stainless Steel Square Pipe | 25 x 25 x 1.5 mm | 1.15 |

| Austenitic Stainless Steel Square Pipe | 25 x 25 x 2.0 mm | 1.50 |

| Martensitic Stainless Steel Square Pipe | 25 x 25 x 3.0 mm | 2.22 |

| Austenitic Chromium Nickel Stainless Steel Square Pipe | 30 x 30 x 1.2 mm | 1.11 |

| Chromium Nickel Stainless Steel Square Pipe | 30 x 30 x 1.5 mm | 1.37 |

| Chromium Stainless Steel Square Pipe | 30 x 30 x 2.0 mm | 1.84 |

| Ferritic Stainless Steel grade Square Pipe | 30 x 30 x 3.0 mm | 2.72 |

| Austenitic Stainless Steel grade Square Pipe | 40 x 40 x 1.2 mm | 1.50 |

| Martensitic Stainless Steel grade Square Pipe | 40 x 40 x 1.5 mm | 1.86 |

| Austenitic and Ferritic Stainless Steel Square Pipe | 40 x 40 x 2.0 mm | 2.45 |

| Super Austenitic Stainless Steel Square Pipe | 40 x 40 x 3.0 mm | 3.76 |

Our team of experts has extensive experience in the steel tube industry, and we are committed to providing our customers with the best possible service. We work closely with our customers to understand their needs and offer tailored solutions that meet their requirements. Whether you need advice on the best product for your project or assistance with the ordering process, our team is always available to help.

In addition to our steel square tubes, we also offer a range of other steel products, including round tubes, rectangular tubes, and stainless steel tubes. We can provide you with a complete solution for all your steel tubing needs.

ASTM A270 square Tube Size Chart In Mm

| Nominal | SS Square Pipe Schedule 5 | SS Square Pipe Schedule 10 | SS Square Pipe Schedule 40 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inch | MM | Wt./MM | Kg./M | Kg./Ft | Wt./MM | Kg./M | Kg./Ft | Wt./MM | Kg./M | Kg./Ft |

| 1 / 2 | 21 | 1.65 | 0.801 | 0.244 | 2.11 | 0.999 | 0.305 | 2.77 | 1.270 | 0.387 |

| 3 / 4 | 21.30 | 1.65 | 1.020 | 0.311 | 2.11 | 1.280 | 0.390 | 2.87 | 1.680 | 0.512 |

| 1 | 26.70 | 1.65 | 1.290 | 0.393 | 2.77 | 2.090 | 0.637 | 3.38 | 2.500 | 0.762 |

| 1 1 / 4 | 33.40 | 1.65 | 1.650 | 0.503 | 2.77 | 2.690 | 0.820 | 3.56 | 3.380 | 1.030 |

| 1 1 / 2 | 42.20 | 1.65 | 1.900 | 0.579 | 2.77 | 3.110 | 0.948 | 3.68 | 4.050 | 1.230 |

| 2 | 48.30 | 1.65 | 3.340 | 0.728 | 2.77 | 3.920 | 1.200 | |||

| 2 1 / 2 | 73.00 | 2.11 | 3.690 | 1.130 | 3.05 | 5.260 | 1.600 | |||

| 3 | 88.90 | 2.11 | 4.510 | 1.380 | 3.05 | 6.450 | 1.970 | |||

| 3 1 / 2 | 101.60 | 2.11 | 5.190 | 1.580 | 3.05 | 7.400 | 2.260 | |||

When it comes to technical information, Sachiya Steel International’s steel square tubes are made to exacting standards. We use only the highest quality steel to ensure that our tubes meet or exceed industry standards. Our steel square tubes are made using a variety of manufacturing techniques, including hot rolled, cold rolled, and cold drawn methods.

Our steel square tubes are available in a range of sizes, from small diameters to larger, heavier tubes. They are typically measured by their outside dimensions, which can range from ½ inch to 16 inches. The wall thickness of our tubes can also vary, from 0.065 inches to 0.250 inches.

Stainless Steel Square Pipe Chemical Composition Table

| STAINLESS STEEL PIPE GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

We offer a range of finishes for our steel square tubes, including hot dipped galvanized, black, and painted finishes. Our galvanized tubes are ideal for outdoor use, as they are resistant to corrosion and rust. Our black and painted tubes are often used for indoor applications, as they offer a clean and polished appearance.

SS square tube Mechanical Properties

| Material | Heat | Temperature | Tensile Strength | Yield Strength | Elongation %, Min |

|---|---|---|---|---|---|

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

One of the advantages of our steel square tubes is their versatility. They can be easily cut, welded, and formed to create a variety of shapes and sizes, making them ideal for a wide range of construction applications. They are commonly used for framing, fencing, and structural support, but can also be used for machinery and equipment, furniture, and even artistic creations.

At Sachiya Steel International, we are committed to providing our customers with the highest quality steel square tubes. Our tubes are tested and inspected to ensure that they meet or exceed industry standards, and we offer a range of certifications and documentation to verify their quality.

In conclusion, if you need high-quality steel square tubes for your construction project, Sachiya Steel International is the ideal choice. With our commitment to quality, versatility, and technical excellence, we can provide you with the right product to meet your needs. Contact us today to learn more about our products and services.