Quick Release Coupling Manufacturer in India

Quick Release Coupling Manufacturer in India

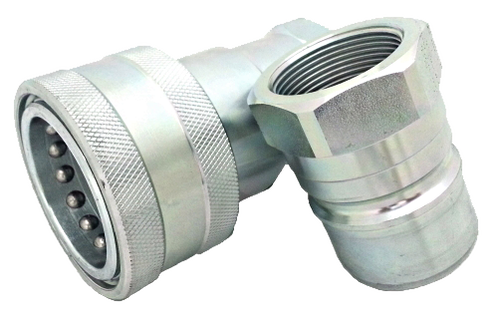

Sachiya Steel International is a trusted name in the industry for manufacturing and exporting Quick Release Coupling. The offered coupling is used in various industries including aeronautics and auto-mobiles. It is robust, resistant to high pressure, non corrosive and dimensionally accurate. This coupling ensures hassle free operations of the air assisted sprayers and prevents leakage of fluids.

Quick Release Connectors Suppliers in Mumbai at low price according to -40* C TO 300*C media temperature

quick release hose couplings at times improve the efficiency of the application due to their custom design and compact size. The design of Pressure Washer Quick Release Coupling is such that the male end fits into the female socket that creates a secure and leak proof seal. high pressure quick release coupling is used for hydraulic wrench, emergency cutting tools, construction equipment, and industrial machinery. Quick Couplings are used in machinery that displays high pressure and vibration. Quick Disconnect Coupling that is designed to work under high pressure has a flat face design with a patented locking sleeve. Qrc needs to be connected between the locking pin and the release notch. Push Pull Couplings are made up of plastic or metal and are said to be light in weight. They can be produced in disposable material for cleanliness and hygiene purposes.

Quick release couplings are fitting are used to mate fluid lines with system equipment that requires frequent connecting and disconnecting. They are used in both pneumatic and hydraulic applications to build or discontinue the connection of a fluid pipeline.

It is well known as quick coupler, quick coupling or quick connect coupling. Quick coupling can be made of stainless steel SS316, carbon steel and brass material for practically every application contingency. The fittings size is available from 1/4” to 2”. The working pressure will be determined depending on the body size.

Hydraulic Quick Release Coupling is found in air, water, steam, and vacuum distribution system. The disconnection of lines leads to a rapid loss of fluid and hence they are connected with Qdc Coupling to prevent the rapid loss during disconnection. Stucchi Italy Quick Release Coupling is used to speed up the work and reduce cost. Din Couplings have made it easy to connect electrical equipment for operation. Holmbury Uk Couplings are well known to increase the output and reduce the downtime of the application. Nitto Interchangeable Series Qrc has eliminated the need for valves and screws in the pneumatic and hydraulic system. Female X Female Qrc is known to prevent the loss of expensive hydraulic fluid.

Quick Release Coupling Specification

| BRAND NAME | SACHIYA STEEL INTERNATIONAL |

| SIZE | 1/8″ TO 4″ |

| THREAD | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| CONNECTION | FEMALE TO FEMALE, FEMALE TO MALE, MALE TO MALE, MALE TO HOSE BARBED |

| PRESSURE RATING | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI |

| MEDIA | HYDRAULIC OIL, AIR, WATER, GAS, STEAM, HOT WATER , COLD WATER , SEA WATER , CHEMICAL, FUEL, VACUUMS |

| MEDIA TEMPERATURE | (-40* C TO 300*C ) RANGE AS PER PRESSURE |

| BODY TYPE | BAR STOCK |

| SEAL | NITRILE, VITON, EPDM |

| EQUIVALENT BRANDS | PARKER, STUCCHI, HOLMBURY, HANSEN, FASTER, STAUFF |

| MATERIAL | SS 316, SS 304, SS 316 TI, COPPER, BRASS, DUPLEX, CS, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L, TITANIUM & ALL OTHER ALLOYS |

Male X Hose Qrc size depends upon the end use of the product. While purchasing Male X Male Qrc it is important to understand the pressure induced by the fluid system and the size of the system. Screwed Type Qrc is also widely used in many industries however care needs to be taken with regards to the fluid type and flow rate of the fluid. Ss 316 Quick Release Coupling is made up of high carbon grade of nickel and chromium when compared to its other version the Ss 304 Qrc grade.

What Is Quick Release Coupling ?

The fitting design is simple and easy to install, example a male end inserts into a female end to make a secure and leak-tight sealing. They are being called as push-in connect because the connection requires a quick push only. The fitting is manufactured according to different standard including ISO 7241-A, ISO 7241-B, Gromelle 6000, Hansen W6000, Parker 60, which are subjected to different industry applications.

Couplings are designed to change the connections without the use of tools or special devices. Quick Release Coupling is one such coupling that eliminates the need to close valves or bleed the system. quick release coupling manufacturers in India manufacture these couplings for various industries as they are high in demand due to their resistance to general corrosion. Quick Release Hose Couplings For Water offer leak-free performance with lightweight construction. quick release coupling for air has a pressure rating of 200 psi. Quick Release Connectors have a quick disconnect facility. Quick Release Hose Connectors are used to connect fluid lines to equipment that requires repeat connections and disconnections.

What size is a quick connect fitting?

The smaller the pipe size (OD), the higher pressure the fitting can withstand and it works respectively for different pipe size (OD). The fitting safety factor is 4.

|

Size

|

ISO 7241-A Norm (Bars)

|

ISO 7241-B Norm (Bars)

|

203 Series TGW (Bars)

|

|

1/4″

|

350

|

400

|

950

|

|

3/8″

|

300

|

380

|

750

|

|

1/2″

|

300

|

350

|

750

|

|

3/4″

|

250

|

320

|

650

|

|

1″

|

230

|

300

|

450

|

|

1 1/4″

|

230

|

280

|

450

|

|

1 1/2″

|

200

|

140

|

300

|

|

2″

|

130

|

100

|

300

|

Table 1: Working Pressure According to Different Size and Standard

Price Of Quick Release Hose Couplings For Water

|

Description

|

Price

|

| Pneumatic Quick Coupling Air Hose Quick Release Coupling C-Type Carbon Steel Coupling | US $ 0.2-2.8 / Piece |

| Hydraulic Hose Fitting Nipple Pipe Quick Release Coupling | US $ 0.99-9.99 / Piece |

| Steel Screw Locked High Pressure 700 Bar Hydraulic Quick Release Coupling | US $ 1-10 / Set |

| Stainless Steel Pneumatic Quick Coupler Air Hose Quick Connector Quick Release Air Coupling | US $ 0.5-4.6 / Piece |

| 1/2 Close Type Stainless Steel 304 Hydraulic Quick Release Coupling | US $ 2-10 / Set |

| Stainless Steel 304 304L Quick Connect Coupling | US $ 0.3-0.5 / Piece |

| Brass Elbow Quick Release Coupling with Hose Barb Fitting | US $ 1-5 / Piece |

| Quick Release Connector Plugs/ Mold Quick Coupling | US $ 0.2-1 / Piece |

QUICK RELEASE COUPLING |

QUICK DISCONNECT COUPLING |

PUSH PULL COUPLINGS |

QUICK COUPLINGS |

HYDRAULIC QUICK RELEASE COUPLING |

QRC |

QDC COUPLING |

DIN COUPLINGS |

STUCCHI ITALY QUICK RELEASE COUPLING |

HOLMBURY UK COUPLINGS |

NITTO INTERCHANGEABLE SERIES QRC |

HIGH PRESSURE QUICK RELEASE COUPLING |

3000 PSI QUICK RELEASE COUPLING |

6000 PSI QUICK RELEASE COUPLING |

FEMALE X FEMALE QRC |

FEMALE X FEMALE QRC |

MALE X HOSE QRC |

MALE X MALE QRC |

SCREWED TYPE QRC |

QRC MALE ADAPTOR |

QRC FEMALE ADAPTOR |

How do you identify a hydraulic quick coupling?

|

Quick Coupling Standard

|

ISO 7241-A Norm

|

ISO 7241-B Norm

|

203 Series TGW

|

|

Working Pressure

|

Up to 350 Bars

|

Up to 400 Bars

|

Up to 950 Bars

|

|

Connection Type

|

Push-in type

|

Push-in type

|

Threaded type

|

|

Material Type

|

|

|

|

|

Working temperature

|

|

|

|

|

Equivalent Design

|

|

|

|

Size Chart Of Quick Release Coupling For Air

|

Size

|

ISO 7241-B Norm (Bars)

|

ISO 7241-A Norm (Bars)

|

203 Series TGW (Bars)

|

|

3/8″

|

380

|

300

|

750

|

|

1/4″

|

400

|

350

|

950

|

|

1 1/2″

|

140

|

200

|

300

|

|

3/4″

|

320

|

250

|

650

|

|

1/2″

|

350

|

300

|

750

|

|

1 1/4″

|

280

|

230

|

450

|

|

1″

|

300

|

230

|

450

|

|

2″

|

100

|

130

|

300

|

How does a quick connect fitting work?

ISO 7241-A standard is versatile for use in hydraulic application for equipment maintenance or operation system. The fitting design is either a poppet valve or ball closing system. The poppet valve and a metal perch are used to maintain valve alignment and prevent flow duplication. Coupler sleeve and nipple body are hardened to be damage resistant and the standard end configurations include female pipe and straight thread of NPT or BSPP.

ISO 7241-B or Parker 60 standard are poppet valves along with a metal to metal valve stop maintains valve alignment. It used to prevent flow duplication. The standard end configuration is female pipe thread of NPT or BSPP. It is generally for applications with lower life cycle and no severe cyclic pressure fluctuations, essentially applied in steady pressure during an operating cycle. The common applications include mine roof support system, hydraulic jacks and high pressure fluid transfer.

Screw end Gromelle W6000 or 203 Series TGW quick coupling is used to connect pipes under high pressure inline systems and high impulse hydraulic applications where fluid lines require fast and easy connection. Screw locking mechanism such as the 203 Series TGW provides exceptional resistance to severe hydraulic loads. This quick coupling is designed for severe conditions where hydraulic shocks, system vibrations or hose bending are possible.

|

Quick Coupling Standard

|

ISO 7241-A Norm

|

ISO 7241-B Norm

|

203 Series TGW

|

|

Applications

|

|

|

|

Table 3: Application in Different Industry -ring material

Available Standard Material

STAINLESS STEEL QUICK RELEASE COUPLING |

SS 304 QUICK RELEASE COUPLING |

SS 316 QUICK RELEASE COUPLING |

CS QUICK RELEASE COUPLING |

BRASS QUICK RELEASE COUPLING |

DUPLEX QUICK RELEASE COUPLING |

SUPER DUPLEX QUICK RELEASE COUPLING |

INCONEL 625 QUICK RELEASE COUPLING |

MONEL 400 QRC |

HASTELLOY C276 QUICK RELEASE COUPLING |

ALLOY 20 QUICK RELEASE COUPLING |

6MO QUICK RELEASE COUPLING |

TITANIUM QUICK RELEASE COUPLING |

CUPRO NICKEL 70 – 30 QRC |

CUPRO NICKEL 90 – 10 QRC |

Hydraulic Quick Coupling Identification Method

|

Quick Coupling Standard

|

ISO 7241-B Norm

|

ISO 7241-A Norm

|

203 Series TGW

|

|

Connection Type

|

Push-in type

|

Push-in type

|

Threaded type

|

|

Working Pressure

|

Up to 400 Bars

|

Up to 350 Bars

|

Up to 950 Bars

|

|

Working temperature

|

|

|

|

|

Material Type

|

|

|

|

|

Equivalent Design

|

|

|

|

Quick Release Connectors Equivalent Material Grade

|

DESCRIPTION

|

CASTING

|

FORGING

|

BARSTOCK

|

UNS GRADE

|

|---|---|---|---|---|

|

Low Temp Carbon

|

A352 LCB

|

A350 LF2

|

A350 LF2

|

K03011

|

|

Carbon Steel

|

A216 WCB

|

A105

|

A105

|

K30504

|

|

3 1/2 Nickel Steel

|

A352 LC3

|

A350 LF3

|

A350 LF3

|

K32025

|

|

High Yield Steel

|

–

|

A694 F60

|

A694 F60

|

K03014

|

|

1 1/4 Chrome, 1/2 Moly

|

A217 WC6

|

A182 F11

|

A182 F11

|

K11597

|

|

5 Chrome, 1/2 Moly

|

A217 C5

|

A182 F5

|

A182 F5

|

K41545

|

|

9 Chrome, 1 Moly

|

A217 WC6

|

A182 F9

|

A182 F9

|

K90941

|

|

2 1/4 Chrome, 1 Moly

|

A217 WC9

|

A182 F22

|

A182 F22

|

K21590

|

|

304

|

A351 CF8

|

A182 F304

|

A276 or A479 304

|

S30400

|

|

13 Chrome

|

A351 CA15

|

A182 F6A

|

A276 or A479 410

|

S41000

|

|

316

|

A351 CF8M

|

A182 F316

|

A276 or A479 316

|

S31600

|

|

304L

|

A351 CF3

|

A182 F304L

|

A276 or A479 304L

|

S30403

|

|

317L

|

A351 CG8M

|

A182 F317L

|

A276 or A479 317L

|

S31703

|

|

316L

|

A351 CF3M

|

A182 F316L

|

A276 or A479 316L

|

S31603

|

|

347

|

A351 CF8C

|

A182 F347

|

A276 or A479 347

|

S34700

|

|

321

|

–

|

A182 F321

|

A276 or A479 321

|

S32100

|

|

Alloy 400

|

A494 M35-1

|

B564 N04400

|

B164 N04400

|

N04400

|

|

17-4PH

|

–

|

A564 630

|

–

|

S17400

|

|

Alloy 800

|

–

|

B564 N08810

|

B408 N08800

|

N08800

|

|

Alloy K500

|

–

|

–

|

B865 N05500

|

N05500

|

|

Alloy 600

|

A494 CY40

|

B564 N06600

|

B166 N06600

|

N06600

|

|

Alloy 825

|

–

|

–

|

B425 N08825

|

N08825

|

|

Alloy B2

|

A494 N 12MV

|

B564 N10665

|

B335 N10665

|

N10665

|

|

Alloy 625

|

A494 CW 6MC

|

B564 N06625

|

B446 N06625

|

N06625

|

|

Alloy C22

|

A494 CX2MW

|

B574 N06022

|

B574 N06022

|

N06022

|

|

Alloy C

|

A494 CW6M

|

–

|

–

|

N10002

|

|

22% Duplex

|

A890 Gr 4A

|

A182 F51

|

A276 or A479 S31803

|

S31803

|

|

Alloy C276

|

A494 CW12 MW

|

B564 N10276

|

B574 N10276

|

N10276

|

|

25% Duplex

|

A890 Gr 6A

|

A182 F53

|

A276 or A479 S32750 or 60

|

S32750 or 32760

|

|

904L

|

–

|

B625 N08904

|

B649 N08904

|

N08904

|

|

254SMO

|

A351 CK3MCuN

|

A182 F44

|

A182 F44

|

S31254

|

|

Titanium

|

B367 C2

|

B381 F2

|

B348 Gr 2

|

R50400

|

Quick Release Couplings Types

- ISO 7241A Series Coupling

- ISO 7241 B Series Coupling

- ISO 16028 Coupler

- ISO 5675 Couplers

- Screwed To Connect Quick Release Coupling

- Double Check Valve Qrc

- Single Check Valve Qrc

- Through Type Qrc

- Minimess Test Couplings

- Brass Quick Release Coupling

- Camlock Couplings

Variants Of Pressure Washer QRC

- Plug-in or screw coupling

- with or without check valve

- optional with additional pressure relief (coupling under residual pressure)

- flat-sealing (leakage-free), cone-sealing or ball-sealing

- optional with dust plug, dust cap

- pipe, Bulkhead, hose or block integration

Hydraulic Quick Release Coupling Application

- Power Plant

- Refinery

- Water Treatment Plant etc.

- Petrochemical Plant

- Ship Building

- Offshore Platform

HSN Code Of High Pressure Quick Release Coupling

| HS Code | Description |

|---|---|

| 84819090 | COVERING CONSIGNMENT OF: Quick Release Coupling 1/2 Male X Female Pressure : 700Bars Material : SS 304 |

| 84818090 | QUICK RELEASE COUPLING INSERT |

| 73072900 | HOSE COUPLING & ADAPTOR:S S COUPLING & ADAPTOR (GDV TYPE QUICK RELEASE COUPLER)SIZE 1/2 |

| 84819090 | COVERING CONSIGNMENT OF: Quick Release Coupling 1/2 Male X Female Pressure : 100Bars Material: SS 304 |

| 90269000 | EXTRA QUICK RELEASE COUPLING FOR BOTH END |

| 84311090 | QUICK RELEASE COUPLING WITH ALUMINIUM DUST CAPS WITH SET |

| 84161000 | HOSE,ADAPTORS & QUICK RELEASE COUPLING FOR START UP BURNER |

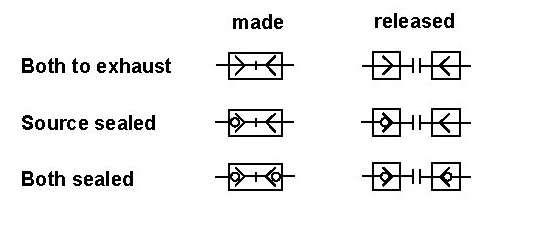

Push Pull Couplings Symbol

Push Pull Couplings Symbol

Quick Disconnect Coupling Advantages

- Designed to withstand high-pressure peaks and pulses

- When connected the male and female halves can rotate, even under pressure, thus avoiding any torsional stress in the flexible hoses

- Positive, quick connection ensured by the snap together locking ball system

- Poppet valve seals have shockproof protective edges

- Poppet valves have balanced springs and calibrated oil flow passages to minimize the pressure drop

How do you use quick connect fittings?

- Helps to keep contaminants out of fluid system.

- Protection from environmental dirt and grit which prolongs the coupling life and helps to keep maintain the fitting in

- excellent working condition.

- Colour coded plug and cap help to visually identify connecting lines.

- Tether straps keep the plug and cap nearby when coupling halves are connected.