Stainless Steel Tube Manufacturers In India

Stainless Steel Tube Manufacturers In India

We are leading stainless steel tube manufacturers in India, Supplier, Dealers, and Exporter of Stainless Steel Tubes in India. Our Stainless Steel Tubes are available in different sizes, shapes, and grades. We supply these Tubes in most of the major Indian cities in more than 20 States. We Sachiya Steel International offer different types of grades like Stainless Steel Tubes, Super Duplex Steel Tubes, Duplex Steel Tubes, Carbon Steel Tubes, Alloys Steel Tubes, Nickel Alloys Tubes, Titanium Steel Tubes, Inconel Steel Tubes, Aluminium Tubes, etc.

About Stainless Steel Tubes

Household and industrial gas lines are usually made of stainless steel tubing as well. If this tubing has eroded, become rusty or broken down due to heat or weathering, then it may be made of galvanized steel, copper or some blend of other metals that all have a shorter shelf life than stainless steel.

Applications & Uses of Stainless Steel Tubes

Stainless steel tubing is used in a variety of industries.

- It is used in aircraft hydraulic lifts.

- These use small amounts of nickel and large percentages of chromium.

- Many factories, mills, and production lines use these components for their machines or in the manufactured products.

| Stainless steel Tubes | Specifications | |||

|---|---|---|---|---|

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS | |||

| Standard | ASME/ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 | |||

| Tubes Size | 1/2″OD TO 8″OD | |||

| Type | Seamless/ erw/ welded/semi welded in round, square, rectangular, coil form, u shape and hydraulic. Tubes | |||

| Grades | ||||

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L | |||

| Super Duplex Steel | S32750 | |||

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. | |||

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 | |||

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. | |||

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 | |||

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI | |||

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L | |||

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G | |||

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum | |||

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 | |||

| Niobium | ASTM B394, R04200 R04210 | |||

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc | |||

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten | |||

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc | |||

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. | |||

| Tantalum | Tantalum – Grade 1. | |||

| Monel | Monel 400, Monel k500 | |||

| MU-METAL | MU-METAL | |||

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 | |||

| Beryllium Copper | Alloy 25 UNSC17200 | |||

| Aluminum | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 | |||

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 | |||

Stainless Steel Tube Packaging

Stainless Steel Tube may be furnished bare or coated and with capped ends. pipes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of Stainless Steel Tube may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.

Stainless Steel Tube Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

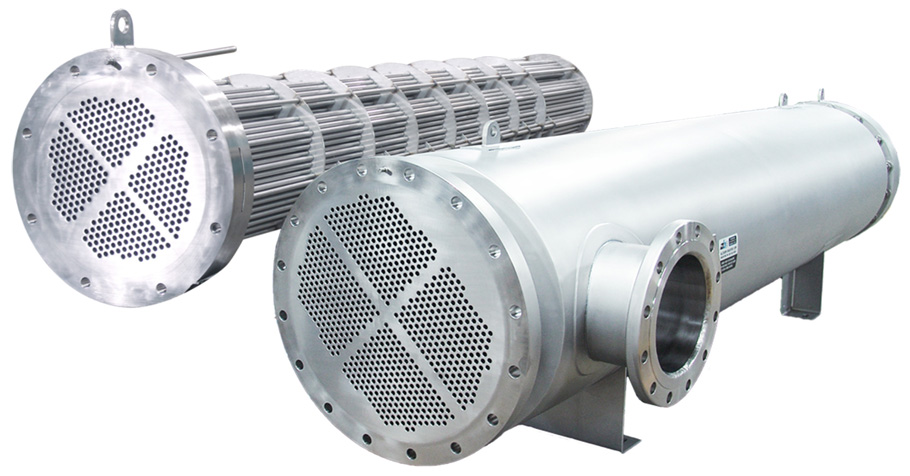

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Stainless Steel Tube Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRITE CONTENT as per norms if requested by clients.

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third-Party Inspection Report, etc

Stainless Steel Tube Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and Macro Test

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Documentation

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- Form A for the purposes of the Generalized System of Preferences (GSP)

Country’s We Export

Venezuela, Iraq, United Kingdom, Russia, United Arab Emirates, Croatia, Indonesia, Oman, Kazakhstan, Israel, Kenya, Iran, Bahrain, Bhutan, Colombia, Serbia, Pakistan, Czech Republic, Turkey, Ukraine, Poland, Bulgaria, France, Chile, Slovakia, Belgium, Iran, Ireland, Qatar, Sri Lanka, Sweden, Brazil, Bolivia, Taiwan, Jordan, South Africa, Switzerland, Tibet, Norway, India, Ghana, Costa Rica, Hungary, New Zealand, Vietnam, Ecuador, Afghanistan, Algeria, Peru, Netherlands, Argentina, Austria, Malaysia, Thailand, Portugal, Zimbabwe, Mongolia, Lebanon, Trinidad & Tobago, Tunisia, Mexico, Greece, Angola, Hong Kong, Denmark, Nepal, Finland, Chile, Poland, Yemen, Nigeria, Italy, Bangladesh, Australia, Macau, Azerbaijan, Saudi Arabia, Japan, Gabon, Philippines, Singapore, United States, Namibia, Romania, South Korea, Germany, Puerto Rico, Estonia, Morocco, Belarus, Nigeria, Mexico, Spain, China, Canada, Libya, Lithuania, Kuwait, Gambia, Egypt.