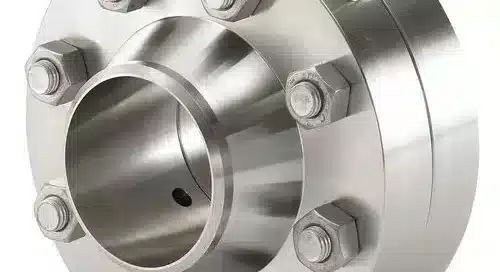

Stainless Steel 904L Orifice Flange Manufacturers in India

Stainless Steel 904L Orifice Flange Manufacturers in India – Sachiya Steel International

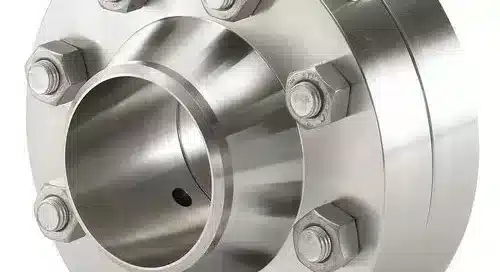

When it comes to Stainless Steel 904L Orifice Flange manufacturers in India, Sachiya Steel International Private Limited takes the lead. We are renowned for our precision-engineered flanges, designed to meet the demanding needs of various industries. With an emphasis on quality, durability, and compliance with international standards, our orifice flanges offer both reliability and exceptional performance.

What Is a Stainless Steel 904L Orifice Flange?

An orifice flange plays a crucial role in industrial pipelines by helping monitor and control fluid or gas flow. Installed alongside an orifice meter or plate, it restricts the flow and ensures precise measurement. Thus, industries benefit from enhanced control and efficient operations.

Stainless Steel 904L, an austenitic alloy, offers superior resistance to corrosion, making it perfect for environments that involve aggressive chemicals or high temperatures. Due to its outstanding mechanical properties, this alloy performs well even under extreme operating conditions.

Why Choose Stainless Steel 904L for Orifice Flanges?

Stainless Steel 904L provides several advantages, especially for critical applications. Here are the key reasons industries rely on this material:

- Excellent Corrosion Resistance: It withstands both acidic and chloride-rich environments without deteriorating.

- High Nickel and Molybdenum Content: These elements ensure resistance to pitting and crevice corrosion.

- Non-Magnetic Nature: It becomes ideal for applications in sensitive environments, such as the pharmaceutical industry.

- Superior Mechanical Strength: The material remains robust even under high pressure and fluctuating temperatures.

- Longevity and Minimal Maintenance: This alloy reduces maintenance needs, ensuring a longer lifespan and better cost efficiency.

As a result, Stainless Steel 904L orifice flanges provide exceptional value and reliability, especially in industries where performance is critical.

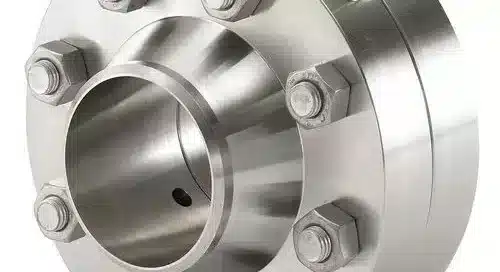

Specifications of Stainless Steel 904L Orifice Flanges

| Specification | Details |

|---|---|

| Standard | ASTM A182, ASME SA182 |

| Material Grade | Stainless Steel 904L |

| Flange Type | Orifice Flange |

| Size Range | ½” to 48” |

| Pressure Rating | Class 150 to Class 2500 |

| Facing | Raised Face (RF), Flat Face (FF), RTJ |

| Ends | Flanged Ends |

| Surface Finish | Smooth, Serrated, or Custom |

| Certification | ISO, PED, NACE, and more |

Applications of Stainless Steel 904L Orifice Flanges

Thanks to its versatile properties, SS 904L orifice flanges are utilized across several industries. Below are some key areas of application:

- Oil & Gas Industry: These flanges help monitor the flow of oil, gas, and refined products.

- Chemical Processing: With excellent resistance to harsh chemicals, these flanges ensure smooth operations in chemical plants.

- Pharmaceutical Industry: The non-magnetic nature of SS 904L is ideal for pharmaceutical environments.

- Power Generation: Power plants use these flanges to manage high-pressure steam systems effectively.

- Marine Applications: Since the material resists saltwater corrosion, it performs exceptionally well in marine environments.

Price List of Stainless Steel 904L Orifice Flanges

| Nominal Pipe Size (NPS) | Class | Price (INR) | Price (USD) |

|---|---|---|---|

| ½” | 150 | 600 | 7.50 |

| 1” | 300 | 900 | 11.20 |

| 2” | 600 | 1500 | 18.60 |

| 4” | 900 | 3200 | 39.50 |

| 6” | 1500 | 5100 | 63.00 |

| 10” | 2500 | 9800 | 120.00 |

| 24” | 150 | 16,000 | 195.00 |

| 36” | 300 | 30,500 | 370.00 |

Chemical Composition of Stainless Steel 904L

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.02 max |

| Chromium (Cr) | 19.0 – 23.0 |

| Nickel (Ni) | 23.0 – 28.0 |

| Molybdenum (Mo) | 4.0 – 5.0 |

| Manganese (Mn) | 2.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.035 max |

| Copper (Cu) | 1.0 – 2.0 |

Mechanical Properties of Stainless Steel 904L

| Property | Value |

|---|---|

| Tensile Strength | 490 MPa min |

| Yield Strength (0.2%) | 220 MPa min |

| Elongation (%) | 35 min |

| Hardness (Brinell) | 210 max |

| Operating Temperature | Up to 400°C |

| Impact Resistance | Excellent |

Dimensions of Stainless Steel 904L Orifice Flanges

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Thickness (T) | Bolt Circle Diameter | No. of Bolts |

|---|---|---|---|---|

| ½” | 89 mm | 11.2 mm | 60.3 mm | 4 |

| 1” | 114 mm | 12.7 mm | 79.4 mm | 4 |

| 2” | 152 mm | 15.9 mm | 120.7 mm | 8 |

| 4” | 229 mm | 23.9 mm | 190.5 mm | 8 |

| 6” | 279 mm | 25.4 mm | 241.3 mm | 8 |

| 10” | 406 mm | 28.4 mm | 317.5 mm | 12 |

| 24” | 635 mm | 35.1 mm | 482.6 mm | 16 |

| 36” | 914 mm | 38.1 mm | 635.0 mm | 20 |

Export Countries for Stainless Steel 904L Orifice Flanges

| Region | Countries |

|---|---|

| Asia | UAE, Saudi Arabia, Qatar, Singapore, Malaysia |

| Europe | Germany, UK, France, Italy, Spain |

| North America | USA, Canada, Mexico |

| South America | Brazil, Argentina, Chile |

| Africa | South Africa, Egypt, Nigeria |

| Australia & NZ | Australia, New Zealand |

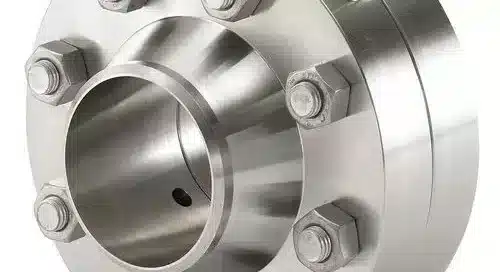

Why Sachiya Steel International Is Your Best Choice

When industries seek reliable Stainless Steel 904L Orifice Flange manufacturers in India, Sachiya Steel International is their top choice. Our products undergo rigorous testing to ensure they meet global standards. Additionally, we offer customized solutions to meet unique project requirements.

We pride ourselves on:

- Precision Manufacturing: We utilize advanced machinery for flawless production.

- Global Distribution Network: With a presence in over 30 countries, we ensure timely deliveries.

- Competitive Pricing: Our products offer excellent value without compromising on quality.

- Exceptional Customer Support: Our team provides assistance throughout the purchasing process.

Conclusion

If you need Stainless Steel 904L Orifice Flange manufacturers in India, Sachiya Steel International Private Limited is the partner you can trust. With a focus on quality, customization, and customer satisfaction, we are committed to delivering the best products and services.

Contact us today to explore our product range and experience the excellence that sets us apart from the competition!