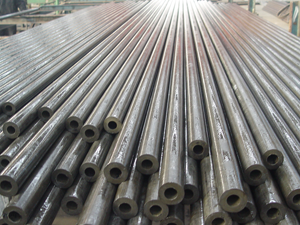

Alloy 20 Tube Suppliers And Manufacturers In India

We are leading Manufacturers, Supplier, Dealers, and Exporter of Alloy 20 Tube in India. Our Alloy 20 Tube is available in different sizes, shapes, and grades. We supply Alloy 20 Tube in most of the major Indian cities in more than 20 States. We Sachiya Steel International offer different types of grades like Stainless Steel tubes, Super Duplex Steel Tubes, Duplex Steel Tubes, Carbon Steel tubes, Alloys Steel tubes, Nickel Alloys tubes, Titanium Steel tubes, Inconel Steel tubes, Aluminium tubes, etc.

Alloy 20 Tube Specification

| Specifications | : | ASTM B 729 ASME SB 729 / ASTM B 468 ASME SB 468 |

| Dimensions | : | ASTM, ASME, and API |

| Tube Size | : | 4 to 219mm W. T.: 0.5 to 20mm |

| Specialized in | : | Large Diameter Size |

| Length | : | Within 13500mm |

| Type | : | Seamless / ERW / Welded / Fabricated |

| Form | : | Round, Hydraulic Etc |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

Types of Alloy 20 Welded Tubes

|

Alloy 20 Seamless Tube | Alloy 20 Seamless Tube Alloy 20Cb-3® Seamless Tube Carpenter 20 Seamless Tubing UNS N08020 Seamless Tube WERKSTOFF NR. 2.4660 Seamless Tube ASTM B729 20 Alloy Seamless Tubes |

|

Alloy 20 Welded Tube | Alloy 20 Welded Tube Alloy 20Cb-3® ERW Tube Alloy 20 EFW Tubing Alloy 20 EFW Tube 20 Alloy Welded Tube UNS N08020 Welded Tube WERKSTOFF NR. 2.4660 Welded Tube ASTM B468 Alloy 20 Welded Tubes |

|

Alloy 20 Round Tube | Alloy 20 Round Tube Alloy 20Cb-3® Round Tubing Carpenter 20 Round Tube UNS N08020 Round Tube Alloy UNS N08020 Round Tube ASTM B729 Alloy 20 Round Tubes |

|

Custom Alloy 20 Tube | Alloy 20 Custom Tube Carpenter 20 Custom Tube Incoloy® alloy 20 Custom Tubing UNS N08020 Custom Tube WERKSTOFF NR. 2.4660 Custom Tube ASME SB729 Alloy 20 Custom Tubes |

Alloy 20 Tubes Chemical Composition

| Alloy 20 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 32 – 38 | 0.02 max | 2 – 3 | 1 – 2 | 0.7 max | Bal | 3 – 4 | 0.005 max | 0.02 max | 19 – 21 |

Alloy 20 Tubing Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35000, MPa – 241 | Psi – 80000 , MPa – 551 | 30 % |

Equivalent Grades for Alloy 20 Tubing

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo | – | – | – |

Alloy 20 Tube Packaging

Alloy 20 Tube may be furnished bare or coated and with capped ends. pipes up to 3” OD will be supplied in bundles. In order to prevent rust during sea shipment, bundles of Alloy 20 Tube may be wrapped with polypropylene sheets, and secured with flat steel bands. Over 3” OD will be supplied loose.

Alloy 20 Tube Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Alloy 20 Tube Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRITE CONTENT as per norms if requested by clients.

- EN 10204/3.1B

- Raw Materials Certificate

- 100% Radiography Test Report

- Third-Party Inspection Report, etc

Material Testing

We at Sachiya Steel International ensure that all our materials go through strict quality tests before dispatching them to our clients.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and Macro Test

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Documentation

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Guarantee Letter

- NABL approved Laboratory Test Reports

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- Form A for the purposes of the Generalized System of Preferences (GSP)

Country’s We Export

Venezuela, Iraq, United Kingdom, Russia, United Arab Emirates, Croatia, Indonesia, Oman, Kazakhstan, Israel, Kenya, Iran, Bahrain, Bhutan, Colombia, Serbia, Pakistan, Czech Republic, Turkey, Ukraine, Poland, Bulgaria, France, Chile, Slovakia, Belgium, Iran, Ireland, Qatar, Sri Lanka, Sweden, Brazil, Bolivia, Taiwan, Jordan, South Africa, Switzerland, Tibet, Norway, India, Ghana, Costa Rica, Hungary, New Zealand, Vietnam, Ecuador, Afghanistan, Algeria, Peru, Netherlands, Argentina, Austria, Malaysia, Thailand, Portugal, Zimbabwe, Mongolia, Lebanon, Trinidad & Tobago, Tunisia, Mexico, Greece, Angola, Hong Kong, Denmark, Nepal, Finland, Chile, Poland, Yemen, Nigeria, Italy, Bangladesh, Australia, Macau, Azerbaijan, Saudi Arabia, Japan, Gabon, Philippines, Singapore, United States, Namibia, Romania, South Korea, Germany, Puerto Rico, Estonia, Morocco, Belarus, Nigeria, Mexico, Spain, China, Canada, Libya, Lithuania, Kuwait, Gambia, Egypt.