Sachiya Steel International Supplies A Full Range Of Bolt Grade 10.9 Bolts, Grade 10.9 Screw, Grade 10.9 Nuts At Factory Price In India

Grade 10.9 Bolt is a high tensile bolt. These are made up of carbon steels and low boron steels. The material is heat treated by quenched and tempered methods. Sachiya Steel International is One Of The Leading Manufacturer And Exporter Of High Quality Grade 10.9 Bolt products in various dimensions and types. The bolts are produced in a way that they have high tensile strength.

The specification standard used to manufacture the Grade 10.9 Stainless Steel Bolt include medium carbon steel, medium carbon steel alloy and low carbon boron steel. These three grades of steel are heat treated by quenching and tempering the Grade 10.9 Bolt Material. The main features of specified Hex Bolt Class 10.9 include its high tensile strength and good wear resistance.

These features are the reason why the Grade 10.9 Steel Bolts are used in automotive applications and for bolting large and forged parts. The yield strength of the Class 10.9 Bolt is 940 Mpa and the tensile strength of the Grade 10.9 Nuts is 1040 MPa. Bolts Grade 10.9 are characterized by uniformity in their threading, dimensional accuracy as well as their corrosion resistance which is why they are primarily used in applications like construction, Engineering, and structural steelwork in industries such as petrochemicals, Defence, railways, and mechanical.

The 10.9 grade has around 10.9mm diameter and the applications range from motors, engines, railroad equipment and processing equipment. The Class 10.9 Alloy Steel Hex Bolts have a hexagonally shaped head that could be used with appropriate tools for maximum tightening. This is the most common shape of the bolts. The Grade 10.9 Nut Dimensions vary in length from 20mm to 200mm depending on the use case.

The Grade 10.9 Screw is available in a wide range sizes i.e. – standard, coarse and fine sizes. Besides having variability in their sizes, the Class 10.9 Bolt are available in customizable finishes which are done either as required by the buyer or as required by the end use of the product. The Grade 10.9 Steel Bolts can be coated or plated by finishing the surface of the fastener with Black oxide, White Zinc Plating, Yellow Zinc Plating or they could be Hot Dip Galvanized.

We Sachiya Steel International manufacture and export a broad variety of products, including High Tensile Bolts 10.9 Grade in supreme Quality. We have a well-equipped infrastructure facility where our latest machinery assists us in making items of the accurate and finest quality. We are making these Bolts in a variety of specs and sizes, to satisfy the requirements of the clients. Tempering and quenching are also followed on these 10.9 Grade Bolts. Tempering is also done to modify this alloy.

We fabricate these bolts with a modest quantity of carbon steel and a lesser amount of boron steel. Boron is added to such steels to improve their properties. The formability of 10.9 grade bolt chemical composition improves even when trace amounts of boron are added.

The dimensions are governed by the DIN, EN,ISO 4014 and 4017 standards. The HT Class 10.9 Studs are one type of the fasteners that have threaded ends on both sides. The bolts could also be plain, zinc plated or hot dip galvanized in finish. The different finishes are preferred in different application types. The High Tensile Grade 10.9 Screw is a special type that does not need nuts to fix it onto other components. This grade of bolts have tensile strength Upto 1040 minimum and yield strength up to 940MPa minimum. The Grade 10.9 Stainless Steel Bolt Material Properties make them applicable in engine parts and components. Please contact us for more information on these products and pricing.

Grade 10.9 bolts are commonly used in high-strength situations, i.e. the automobile sector, in particular, needs. The popularity for high tensile bolts 10.9 grade stems from the significant cost savings they provide over common stainless steel grades such as 304 or 316. When increased corrosion resistance, such as oxidation or pitting, is required, stainless steel bolts are regarded to be a much durable. Although they have a higher rate of corrosion, they compensate for this by having superior mechanical qualities at hotter temperatures.

We Grade 10.9 High Tensile bolts manufacturers offer these bolts to a wide range of industries and are used for a variety of purposes. Bolts made of Alloy Steel Grade 10.9 is used in railroad machinery, air compressors, propellers, and processing machinery. Our consumers value our goods for their excellent quality and endurance. We manufacture these items in accordance with international manufacturing standards. We design these goods so that they may be used to their full potential even under difficult situations.

Specification Chart of 10.9 Grade Bolt

| Grades | Grade 10.9 Bolt |

|---|---|

| Standard | ASTM A324, ASME SA324 |

| Size | Dia M 20 to 100 mm Inch 3/4″ to 3.1/2″ |

| finish | Zinc plated / Plain / Hot dip galvanized |

Chemical Composition Grade 10.9 Nut

| Carbon Steel 10.9 | C | P | S | B |

|---|---|---|---|---|

| 0.20-0.55 | 0.025 | 0.025 | 0.003 |

HT Class 10.9 Studs Mechanical Strength

| Grades | Size Range | PS [MPa] | YS (min) [MPa] | TS (min) [MPa] | Hardness [Rockwell] |

|---|---|---|---|---|---|

| Class 10.9 | 5–100 | 830 | 940 | 1040 | C33–39 |

Grade 10.9 Stainless Steel Bolt Physical Properties

| Class and Material | Nominal Size Range (mm) | Mechanical Properties | ||

|---|---|---|---|---|

| Proof Load (MPa) | Min. Yield Strength (MPa) | Min. Tensile Strength (MPa) | ||

| Class 10.9 Alloy steel, quenched and tempered | 5mm – 100mm | 830 | 940 | 1040 |

Sachiya Steel International is One Of The Leading Manufacturer of Hex Bolt Class 10.9, Hex Head Bolt Grade 10.9 in India. Check Dimension of Hex Bolt Grade 10.9.

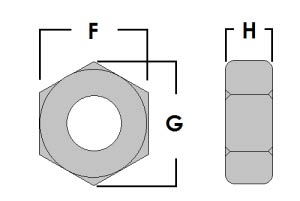

Dimensions Schedule Of Class 10.9 Hex Nuts

| Diameter | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pitch | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 |

| Across Flat (S) Max

Minimum |

7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 510.9 | 63.1 | 68.1 | 73.1 | 78.1 | |

| Thickness (M) Max

Minimum |

3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 18 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 |

| 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 16.9 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | |

| Across corners (E) Min | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.35 | 26.75 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 |

| Minor Dia at thread (min) | 3.242 | 4.134 | 4.917 | 6.647 | 8.376 | 10.106 | 11.835 | 13.835 | 15.294 | 17.294 | 19.294 | 20.752 | 23.752 | 26.211 | 29.211 | 31.67 | 34.67 | 37.129 | 40.129 | 42.587 | 46.587 |

| Minor Dia at thread (maximum) | 3.422 | 4.334 | 5.153 | 6.912 | 8.676 | 10.441 | 12.210 | 14.210 | 15.744 | 17.774 | 19.774 |

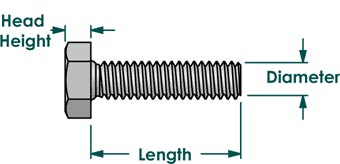

Grade 10.9 Hex Bolts Dimensions

Grade 10.9 Hex Bolts Dimensions

**All measurements in millimeters**

|

DIA |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

M42 |

M45 |

M48 |

M52 |

|

Pitch |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

5 |

||||||||

|

Grade A upto length |

40 |

50 |

60 |

80 |

100 |

120 |

140 |

150 |

Grade A not applicable to these dia’s |

||||||||||||

|

Head Across Flat (S) Nom = Max Min Grade A Grade B |

7 |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

27 |

30 |

34 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

|

6.78 |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

26.67 |

29.67 |

33.38 |

35.38 |

Grade A not applicable to these dia’s |

|||||||||

|

6.64 |

7.64 |

9.64 |

12.57 |

15.57 |

17.57 |

20.16 |

23.16 |

26.16 |

29.16 |

33 |

35 |

40 |

45 |

49 |

53.8 |

510.9 |

63.1 |

68.1 |

73.1 |

78.1 |

|

|

Head Height (K) Nom Tol + or – Grade A Grade B |

2.8 |

3.5 |

4 |

5.3 |

6.4 |

7.5 |

10.9 |

10 |

11.5 |

12.5 |

14 |

15 |

17 |

18.7 |

21 |

22.5 |

25 |

26 |

28 |

30 |

33 |

|

0.125 |

0.15 |

0.18 |

0.215 |

Grade A not applicable to these dia’s |

|||||||||||||||||

|

0.2 |

0.24 |

0.29 |

0.35 |

0.42 |

0.5 |

||||||||||||||||

|

Across corners e Min Grade A Grade B |

7.66 |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.36 |

26.75 |

30.14 |

33.53 |

37.72 |

39.98 |

Grade A not applicable to these dia’s |

||||||||

|

7.5 |

8.63 |

10.89 |

14.2 |

17.59 |

19.85 |

22.78 |

26.17 |

29.56 |

32.95 |

37.29 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

76.95 |

82.6 |

88.25 |

|

|

Thread Length (b) For lengths < or = 125mm For lengths > 125mm <= 200mm For lengths > 200mm |

14 |

16 |

18 |

22 |

26 |

30 |

34 |

38 |

42 |

46 |

50 |

54 |

60 |

66 |

Not specified as full thread recommended |

||||||

|

20 |

22 |

24 |

28 |

32 |

36 |

40 |

44 |

48 |

52 |

56 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

102 |

108 |

116 |

|

|

33 |

35 |

37 |

41 |

45 |

49 |

53 |

57 |

61 |

65 |

69 |

73 |

79 |

85 |

91 |

97 |

103 |

109 |

115 |

121 |

129 |

|

|

Major Dia at thread (min) |

3.838 |

4.826 |

5.794 |

7.76 |

9.732 |

11.701 |

13.682 |

15.682 |

17.623 |

19.623 |

21.623 |

23.577 |

26.577 |

29.522 |

32.522 |

35.465 |

38.465 |

41.437 |

44.437 |

47.399 |

51.399 |

|

Major Dia at thread (max) |

3.978 |

4.976 |

5.974 |

7.972 |

9.968 |

11.966 |

13.962 |

15.962 |

17.958 |

19.958 |

21.958 |

23.952 |

26.952 |

29.947 |

32.947 |

35.94 |

38.94 |

41.937 |

44.937 |

47.929 |

51.929 |

Grade 10.9 Hex Bolts In Bsw/Bsf Threads To Bs 1083-1965

All dimensions in Inches

| DIA | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | 1 3/4 | 2 |

| BSW Pitch (TPI) | 20 | 18 | 16 | 14 | 12 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 5 | 4.5 | |

| BSF PITCH (TPI) | 26 | 22 | 20 | 18 | 16 | 16 | 14 | 12 | 11 | 10 | 9 | 9 | 8 | 8 | 7 | 7 |

| Head Across Flat (S) Min

Max |

0.438 | 0.518 | 0.592 | 0.702 | 0.812 | 0.912 | 1.000 | 1.190 | 1.288 | 1.468 | 1.640 | 1.815 | 2.005 | 2.175 | 2.520 | 2.700 |

| 0.445 | 0.525 | 0.600 | 0.710 | 0.820 | 0.920 | 1.010 | 1.200 | 1.300 | 1.480 | 1.670 | 1.860 | 2.050 | 2.220 | 2.580 | 2.760 | |

| Head height (K) Min

Max |

0.166 | 0.208 | 0.250 | 0.292 | 0.333 | 0.365 | 0.407 | 0.480 | 0.563 | 0.636 | 0.710 | 0.790 | 0.880 | 0.960 | 1.110 | 1.270 |

| 0.176 | 0.218 | 0.260 | 0.302 | 0.343 | 0.375 | 0.417 | 0.500 | 0.583 | 0.666 | 0.750 | 0.830 | 0.920 | 1.000 | 1.170 | 1.330 | |

| Across corners e Max | 0.51 | 0.61 | 0.69 | 0.82 | 0.95 | 1.06 | 1.17 | 1.39 | 1.50 | 1.71 | 1.93 | 2.15 | 2.37 | 2.56 | 2.98 | 3.19 |

| Thread Length b Min | Twice the Dia (2D) | |||||||||||||||

| Major Dia at thread BSW (min) | 0.2427 | 0.3046 | 0.3666 | 0.4285 | 0.4904 | 0.5527 | 0.6147 | 0.7390 | 0.8653 | 0.9897 | 1.1140 | 1.2388 | 1.4879 | 1.7369 | 1.9862 | |

| Major Dia at thread BSW (max) | 0.2488 | 0.3112 | 0.3736 | 0.4360 | 0.4985 | 0.5609 | 0.6233 | 0.7482 | 0.8750 | 1.000 | 1.1250 | 1.250 | 1.500 | 1.750 | 2.000 | |

| Major Dia at thread BSF (min) | 0.2432 | 0.3051 | 0.3671 | 0.4290 | 0.4910 | 0.5533 | 0.6153 | 0.7394 | 0.8658 | 0.9902 | 1.1148 | 1.2395 | 1.3640 | 1.4888 | 1.7380 | 1.9876 |

| Major Dia at thread BSF (max) | 0.2489 | 0.3113 | 0.3737 | 0.4361 | 0.4985 | 0.5610 | 0.6234 | 0.7482 | 0.8750 | 1.000 | 1.1250 | 1.250 | 1.375 | 1.500 | ||

Grade 10.9 Hex Bolts Unc/Unf Threads To Bs 1768-1963

All dimensions in Inches

|

DIA |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

9/16 |

5/8 |

3/4 |

7/8 |

1 |

1 1/8 |

1 1/4 |

1 3/8 |

1 1/2 |

1 3/4 |

2 |

|

UNC Pitch (TPI) |

20 |

18 |

16 |

14 |

13 |

12 |

11 |

10 |

9 |

8 |

7 |

7 |

6 |

6 |

5 |

4.5 |

|

UNF Pitch (TPI) |

28 |

24 |

24 |

24 |

20 |

20 |

18 |

16 |

14 |

12 |

NOT RECOMMENDED |

|||||

|

Head Across Flat (S) Min Max |

0.430 |

0.493 |

0.554 |

0.617 |

0.742 |

0.804 |

0.929 |

1.115 |

1.300 |

1.488 |

1.657 |

1.830 |

2.017 |

2.205 |

2.565 |

2.940 |

|

0.437 |

0.500 |

0.562 |

0.625 |

0.750 |

0.812 |

0.937 |

1.125 |

1.312 |

1.500 |

1.687 |

1.875 |

2.062 |

2.250 |

2.625 |

3.000 |

|

|

Head Height (K) Min Max |

0.153 |

0.201 |

0.233 |

0.281 |

0.313 |

0.361 |

0.393 |

0.463 |

0.543 |

0.597 |

0.678 |

0.773 |

0.838 |

0.934 |

1.074 |

1.203 |

|

0.163 |

0.211 |

0.243 |

0.291 |

0.323 |

0.371 |

0.403 |

0.483 |

0.563 |

0.627 |

0.718 |

0.813 |

0.878 |

0.974 |

1.134 |

1.263 |

|

|

Across corners e (MAX) |

0.505 |

0.577 |

0.650 |

0.722 |

0.866 |

0.938 |

1.083 |

1.300 |

1.515 |

1.732 |

1.948 |

2.165 |

2.382 |

2.598 |

3.031 |

3.464 |

|

Thread Length b (Min) |

2D + 1/4” upto bolt length of 6” and 2D + 1/2” for bolt lengths above 6” |

|||||||||||||||

|

Major Dia at thread ( Class 2A) Min for UNC |

0.2408 |

0.3026 |

0.3643 |

0.4258 |

0.4876 |

0.5495 |

0.6113 |

0.7353 |

0.8592 |

0.9830 |

1.1064 |

1.2314 |

1.3544 |

1.4794 |

1.7268 |

1.9751 |

|

Major Dia at thread (2A) Min for UNF |

0.2425 |

0.3042 |

0.3667 |

0.4281 |

0.4906 |

0.5524 |

0.6149 |

0.7391 |

0.8631 |

0.9868 |

NOT RECOMMENDED |

|||||

|

Major Dia at thread Class 2A Max for UNC |

0.2490 |

0.3113 |

0.3737 |

0.4361 |

0.4985 |

0.5609 |

0.6234 |

0.7482 |

0.8731 |

0.9980 |

1.1228 |

1.2478 |

1.3726 |

1.4976 |

1.7473 |

1.9971 |

Grade 10.9 Washers Dimensions

| DIA | M16 | M20 | M22 | M24 | M27 | M30 | M36 |

| HARDNESS FOR PL. WASHER | 35 TO 45 HRC | ||||||

| Hardness for Hot Dip Galvd washer | 26 HRC | ||||||

| Outer Dia (Max) d2 | 34 | 42 | 44 | 50 | 56 | 60 | 72 |

| Inner Dia (Min) d1 | 18 | 22 | 24 | 26 | 30 | 33 | 39 |

| Thickness (S) | 3.1 TO 4.6 | ||||||

| Tolerance for OD Minus(-) | 1.6 | 1.9 | |||||

| Tolerance for ID Plus(+) | 0.43 | 0.52 | 0.62 | ||||

Hardened And Tempered Washers To Din 6916

All dimensions in mm

|

DIA |

M12 |

M16 |

M20 |

M22 |

M24 |

M27 |

M30 |

M36 |

|

Weight in Kgs for 100 nos |

0.703 |

1.46 |

1.96 |

2.43 |

3.06 |

5.02 |

6.32 |

11.50 |

|

Outer Dia (Max) d2 |

24 |

30 |

37 |

39 |

44 |

50 |

56 |

66 |

|

Inner Dia (Min) d1 |

13 |

17 |

21 |

23 |

25 |

28 |

31 |

37 |

|

Thickness (S) |

3 |

4 |

4 |

4 |

4 |

5 |

5 |

6 |

|

Tolerance for OD Minus(-) |

0.52 |

0.62 |

1 |

1.20 |

||||

|

Tolerance for ID Plus(+) |

0.27 |

0.33 |

0.52 |

0.62 |

||||

|

Tolerance for thickness + or – |

0.30 |

0.60 |

||||||

Dimensions of Grade 10.9 Hex Nuts

Dimensions of Grade 10.9 Hex Nuts

**All measurements in millimeters**

|

DIA |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

M42 |

M45 |

M48 |

M52 |

|

Pitch |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

4.5 |

5 |

5 |

|

Across Flat (S) Max Min |

7 |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

27 |

30 |

34 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

|

6.78 |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

26.16 |

29.16 |

33 |

35 |

40 |

45 |

49 |

53.8 |

510.9 |

63.1 |

68.1 |

73.1 |

78.1 |

|

|

Thickness (M) Max Min |

3.2 |

4.7 |

5.2 |

6.8 |

8.4 |

10.8 |

12.8 |

14.8 |

15.8 |

18 |

19.4 |

21.5 |

23.8 |

25.6 |

28.7 |

31 |

33.4 |

34 |

36 |

38 |

42 |

|

2.9 |

4.4 |

4.9 |

6.44 |

8.04 |

10.37 |

12.1 |

14.1 |

15.1 |

16.9 |

18.1 |

20.2 |

22.5 |

24.3 |

27.4 |

29.4 |

31.8 |

32.4 |

34.4 |

36.4 |

40.4 |

|

|

Across corners (E) Min |

7.66 |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.35 |

26.75 |

29.56 |

32.95 |

37.29 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

71.3 |

76.95 |

82.6 |

88.25 |

|

Minor Dia at thread (min) |

3.242 |

4.134 |

4.917 |

6.647 |

8.376 |

10.106 |

11.835 |

13.835 |

15.294 |

17.294 |

19.294 |

20.752 |

23.752 |

26.211 |

29.211 |

31.67 |

34.67 |

37.129 |

40.129 |

42.587 |

46.587 |

|

Minor Dia at thread (max) |

3.422 |

4.334 |

5.153 |

6.912 |

8.676 |

10.441 |

12.210 |

14.210 |

15.744 |

17.774 |

19.774 |

21.252 |

24.252 |

26.771 |

29.771 |

32.27 |

35.27 |

37.799 |

40.799 |

43.297 |

47.297 |

Grade 10.9 Hex Nuts In Bsw/Bsf Threads To Bs 1083-1965 Threads To Bs 84

All dimensions in inches

|

DIA |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

9/16 |

5/8 |

3/4 |

7/8 |

1 |

1 1/8 |

1 1/4 |

1 3/8 |

1 1/2 |

1 3/4 |

2 |

|

BSW Pitch (TPI) |

20 |

18 |

16 |

14 |

12 |

12 |

11 |

10 |

9 |

8 |

7 |

7 |

– |

6 |

5 |

4.5 |

|

BSF PITCH (TPI) |

26 |

22 |

20 |

18 |

16 |

16 |

14 |

12 |

11 |

10 |

9 |

9 |

8 |

8 |

7 |

7 |

|

WIDTH Across Flat (S) Min Max |

0.438 |

0.518 |

0.592 |

0.702 |

0.812 |

0.912 |

1.000 |

1.190 |

1.288 |

1.468 |

1.640 |

1.815 |

2.005 |

2.175 |

2.520 |

2.700 |

|

0.445 |

0.525 |

0.600 |

0.710 |

0.820 |

0.920 |

1.010 |

1.200 |

1.300 |

1.480 |

1.670 |

1.860 |

2.050 |

2.220 |

2.580 |

2.760 |

|

|

Thickness (M) Min Max |

0.190 |

0.240 |

0.302 |

0.365 |

0.427 |

0.490 |

0.552 |

0.677 |

0.740 |

0.865 |

0.990 |

1.105 |

1.230 |

1.355 |

1.605 |

1.730 |

|

0.200 |

0.250 |

0.312 |

0.375 |

0.437 |

0.500 |

0.562 |

0.687 |

0.750 |

0.875 |

1.000 |

1.125 |

1.250 |

1.375 |

1.625 |

1.750 |

|

|

Across corners (Max inches) |

0.51 |

0.61 |

0.69 |

0.82 |

0.95 |

1.06 |

1.17 |

1.39 |

1.50 |

1.71 |

1.93 |

2.15 |

2.37 |

2.56 |

2.98 |

3.19 |

|

Minor Dia at thread BSW (min) |

0.1860 |

0.2413 |

0.2950 |

0.3461 |

0.3932 |

0.4557 |

0.5086 |

0.6220 |

0.7328 |

0.8400 |

0.9420 |

1.0670 |

– |

1.2866 |

1.4938 |

1.7154 |

|

Minor Dia at thread BSW (max) |

0.2030 |

0.2594 |

0.3145 |

0.3674 |

0.4169 |

0.4794 |

0.5338 |

0.6490 |

0.7620 |

0.8720 |

0.9776 |

1.1026 |

– |

1.3269 |

1.5408 |

1.7668 |

|

Minor Dia at thread BSF (min) |

0.2008 |

0.2543 |

0.3110 |

0.3663 |

0.4200 |

0.4825 |

0.5336 |

0.6432 |

0.7586 |

0.8720 |

0.9828 |

1.1078 |

1.2150 |

1.3400 |

1.5670 |

1.8170 |

|

Minor Dia at thread BSF (max) |

0.2125 |

0.2684 |

0.3280 |

0.3844 |

0.4395 |

0.5020 |

0.5549 |

0.6669 |

0.7838 |

0.8990 |

1.0120 |

1.1370 |

1.2470 |

1.3720 |

1.6026 |

1.8526 |

Grade 10.9 Hex Nuts In Unc/Unf Threads To Bs 1768-1963 Threads To Bs 1580

All dimensions in inches

|

DIA |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

9/16 |

5/8 |

3/4 |

7/8 |

1 |

1 1/8 |

1 1/4 |

1 3/8 |

1 1/2 |

1 3/4 |

2 |

|

UNC Pitch (TPI) |

20 |

18 |

16 |

14 |

13 |

12 |

11 |

10 |

9 |

8 |

7 |

7 |

6 |

6 |

5 |

4.5 |

|

UNF Pitch (TPI) |

28 |

24 |

24 |

24 |

20 |

20 |

18 |

16 |

14 |

12 |

NOT RECOMMENDED |

|||||

|

Width Across Flat (S) Min Max |

0.430 |

0.493 |

0.554 |

0.617 |

0.742 |

0.804 |

0.929 |

1.115 |

1.300 |

1.488 |

1.657 |

1.830 |

2.017 |

2.205 |

2.565 |

2.940 |

|

0.437 |

0.500 |

0.562 |

0.625 |

0.750 |

0.812 |

0.937 |

1.125 |

1.312 |

1.500 |

1.687 |

1.875 |

2.062 |

2.250 |

2.625 |

3.000 |

|

|

Thickness (M) Min Max |

0.214 |

0.261 |

0.323 |

0.370 |

0.432 |

0.479 |

0.542 |

0.631 |

0.740 |

0.844 |

0.949 |

1.037 |

1.147 |

1.251 |

1.470 |

1.684 |

|

0.224 |

0.271 |

0.333 |

0.380 |

0.442 |

0.489 |

0.552 |

0.651 |

0.760 |

0.874 |

0.989 |

1.087 |

1.197 |

1.311 |

1.530 |

1.754 |

|

|

Across corners (E) Max |

0.505 |

0.577 |

0.650 |

0.722 |

0.866 |

0.938 |

1.083 |

1.300 |

1.515 |

1.732 |

1.948 |

2.165 |

2.382 |

2.598 |

3.031 |

3.464 |

|

Minor Dia at thread (min) UNC (2B) |

0.1960 |

0.2520 |

0.3070 |

0.3600 |

0.4170 |

0.4720 |

0.5270 |

0.6420 |

0.7550 |

0.8650 |

0.9700 |

1.0950 |

1.1950 |

1.3200 |

1.5340 |

1.7590 |

|

Minor Dia at thread (max) UNC (2B) |

0.2070 |

0.2650 |

0.3210 |

0.3760 |

0.4340 |

0.4900 |

0.5460 |

0.6630 |

0.7780 |

0.8900 |

0.9980 |

1.1230 |

1.2250 |

1.3500 |

1.5680 |

1.7950 |

|

Minor Dia at thread (min) UNF (2B) |

0.2110 |

0.2670 |

0.3300 |

0.3830 |

0.4460 |

0.5020 |

0.5650 |

0.6820 |

0.7980 |

0.9100 |

NOT RECOMMENDED |

|||||

|

Minor Dia at thread (max) UNF (2B) |

0.2200 |

0.2770 |

0.3400 |

0.3950 |

0.4570 |

0.5150 |

0.5780 |

0.6960 |

0.8140 |

0.9280 |

||||||

High Strength Friction Grip Hex Nuts In Mm Threads To Is 6623-1985 Grades 8s & 10s

All dimensions in mm

|

DIA |

M16 |

M20 |

M22 |

M24 |

M27 |

M30 |

M36 |

|

Pitch |

2 |

2.5 |

2.5 |

3 |

3 |

3.5 |

4 |

|

Head Across Flat (B) Min |

26.16 |

33 |

35 |

40 |

45 |

49 |

510.9 |

|

Head Across Flat (B) Max |

27 |

34 |

36 |

41 |

46 |

50 |

60 |

|

Height (H) Min Max |

16.4 |

19.4 |

22.3 |

22.9 |

26.3 |

29.1 |

35 |

|

17.1 |

20.7 |

23.6 |

24.2 |

27.6 |

30.7 |

36.6 |

|

|

Across corners C min |

29.56 |

37.29 |

39.55 |

45.20 |

50.85 |

55.37 |

66.44 |

|

Minor Dia at thread (min) |

14.235 |

17.694 |

19.694 |

21.202 |

24.252 |

26.761 |

32.270 |

|

Minor Dia at thread (max) |

14.610 |

18.144 |

20.144 |

21.702 |

24.752 |

27.321 |

32.870 |

Application of Grade 10.9 Fasteners

- HT Studs uses in Petrochemicals

- Grade 10.9 Nuts uses in Specialty Chemicals

- Grade 10.9 Bolts And Nuts uses in Pharmaceuticals

- HT U Bolts uses in Spiral Welded tube for burner pipes and flues

- Grade 10.9 Fasteners uses in Gas Processing

- HT Fasteners uses in Power Generation

- Grade 10.9 Threaded Rod uses in Sea Water Equipment

- HT Bolts uses in Off-Shore Oil Drilling Companies

- HT Anchor Bolts uses in Heat Exchangers

- HT Fasteners uses in Pharmaceutical Equipment

ASTM A324 HT Grade 10.9 Threaded Rod price

| High Tensile Gr. 10.9 Fasteners Price List | Price Per Pcs |

|---|---|

| High Tensile class 10.9 Socket Head Cap Screw price | USD $3.00 |

| Grade 10.9 Allen bolt price | USD $4.00 |

| High Tensile Class 10.9 Hex head bolt price | USD $6.00 |

| High Tensile Class 10.9 Nuts price | USD $1.20 |

| High Tensile Gr 10.9 Machine bolt price | USD $5.00 |

Grade 10.9 Bolt

Grade 10.9 Bolt is a high tensile bolt. These are made up of carbon steels and low boron steels. The material is heat treated by quenched and tempered methods. Sachiya Steel International is One Of The Leading Manufacturer And Exporter Of High Quality Grade 10.9 Bolt products in various dimensions and types. The bolts are produced in a way that they have high tensile strength.

Product Brand: Sachiya Steel International

Product Currency: INR

Product Price: 100

Price Valid Until: 2026-05-28

Product In-Stock: InStock

5